Femtosekundový laser vyzařuje ultrakrátké světelné pulzy, z nichž každý trvá pouze jednu kvadriliontinu sekundy (10^-15 sekund). Tato neuvěřitelně krátká doba trvání umožňuje přesné zpracování materiálu s minimálním tepelným poškozením, což činífemtosekundové laseryneocenitelné v různých vysoce přesných aplikacích.

Jak fungují femtosekundové lasery?

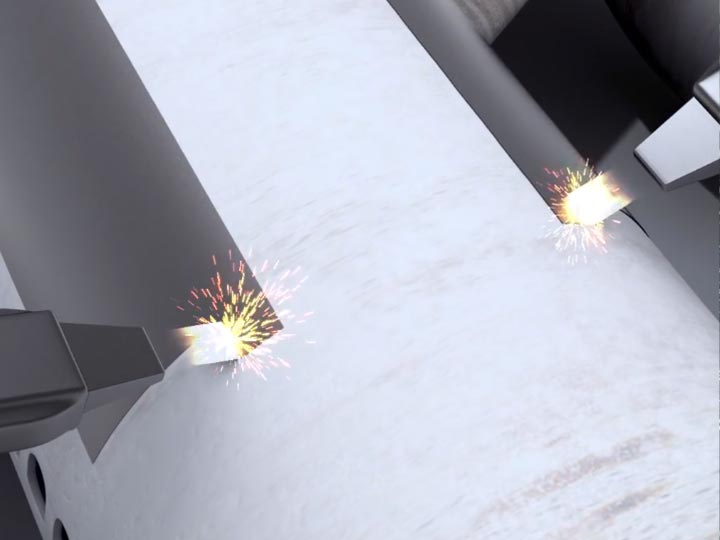

Femtosekundové lasery fungují na principu generování ultrakrátkých pulzů pomocí procesu zvaného synchronizace módů, kde se kombinuje více světelných frekvencí a vytváří se jediný pulz s vysokou intenzitou. Tyto pulzy interagují s materiály prostřednictvím nelineárních absorpčních procesů, což umožňuje přesnou ablaci bez významné difúze tepla.

Klíčové komponenty femtosekundového laserového systému

Zisk středníTypicky titanem dopovaný safír (Ti

) krystal nebo yterbiem dopované vlákno, které zesiluje laserové světlo.

Mechanismus uzamčení režimuZajišťuje generování ultrakrátkých pulzů.

Pulzní kompresorZkracuje dobu trvání pulzu na femtosekundový rozsah.

Systém dodávání paprskůSměruje laserové pulzy s vysokou přesností na cílový materiál.

Výhody ultrarychlých pulzů

Minimální tepelné poškozeníUltrakrátká doba trvání pulzu omezuje ukládání energie na malý objem, čímž se zmenšují tepelně ovlivněné zóny.

Vysoká přesnostUmožňuje mikroobrábění a nanoměřítky.

VšestrannostÚčinný na širokou škálu materiálů, včetně kovů, polymerů a biologických tkání.

Femtosekundové vs. pikosekundové a nanosekundové lasery

Pochopení rozdílů mezi femtosekundovými, pikosekundovými a nanosekundovými lasery je klíčové pro výběr vhodné technologie pro konkrétní aplikace.

Porovnání trvání pulzu

Femtosekundové lasery: 10^-15 sekund

Pikosekundové lasery: 10^-12 sekund

Nanosekundové lasery: 10^-9 sekund

Dopad na zpracování materiálu

Femtosekundové laseryNabízí nejvyšší přesnost se zanedbatelnými tepelnými účinky, ideální pro choulostivé materiály a aplikace vyžadující extrémní přesnost.

Pikosekundové laseryPoskytují rovnováhu mezi přesností a rychlostí zpracování, vhodné pro mikroobráběcí úkoly.

Nanosekundové laseryCenově výhodnější pro odstraňování sypkého materiálu, ale může způsobit značné tepelné poškození.

Vhodnost aplikace

FemtosekundaOční chirurgie, výroba mikroelektroniky a vysoce přesné mikroobrábění.

PikosekundaGravírování, značení a některé lékařské aplikace.

NanosekundaSvařování, řezání a všeobecné zpracování materiálů.

Průmyslové a lékařské aplikace femtosekundových laserů

Femtosekundové lasery způsobily revoluci v mnoha odvětvích díky své bezkonkurenční přesnosti a minimálnímu tepelnému dopadu.

Lékařské aplikace

OftalmologiePoužívá se při operacích LASIK a šedého zákalu pro přesné řezy rohovky, což zlepšuje výsledky léčby pacientů.

NeurochirurgieUmožňuje minimálně invazivní zákroky se sníženým vedlejším poškozením.

Dermatologie: Usnadňuje omlazení pleti a ošetření jizev s vysokou přesností.

Výroba mikroelektroniky a polovodičů

Vzorování obvodůUmožňuje vytváření složitých vzorů na polovodičových destičkách.

Mikroelektromechanické systémy (MEMS)Umožňuje výrobu složitých mikrostruktur nezbytných pro senzory a akční členy.

Letecký a automobilový průmysl

Výroba součástekPoužívá se pro vrtání a řezání vysoce pevných materiálů, jako jsou titanové slitiny, s minimální tepelnou deformací.

Texturování povrchuZlepšuje adhezní a třecí vlastnosti součástí.

Hodinářství a šperky

Přesné gravírováníVytváří složité vzory na cifernících hodinek a špercích.

Zpracování materiáluZvládá jemné materiály, jako je perleť, aniž by je poškodil.

Vědecký výzkum

Ultrarychlá spektroskopieStuduje rychlé chemické reakce a dynamiku elektronů.

Kvantové výpočtyManipuluje s qubity s vysokou přesností pro zpracování informací.

Úvahy o nákladech a údržbě

Femtosekundové lasery sice nabízejí řadu výhod, ale zároveň s sebou nesou vyšší náklady a požadavky na údržbu.

Počáteční investice

Cena femtosekundových laserových systémů se může pohybovat od 100 000 do více než 500 000 dolarů, v závislosti na specifikacích a možnostech.

Provozní náklady

ÚdržbaVyžaduje pravidelný servis pro zajištění optimálního výkonu.

Spotřební materiálSoučásti jako laserové krystaly a optika mohou vyžadovat pravidelnou výměnu.

VýcvikObsluha musí být dostatečně proškolena k bezpečné manipulaci se systémem a jeho údržbě.

Opravy a servis

Vzhledem ke složitosti femtosekundových laserů by opravy měly provádět zkušení odborníci. Mezi běžné úkony údržby patří:

Zarovnání paprskuZajištění správného vyrovnání laserového paprsku pro přesný provoz.

Výměna optických komponentVýměna opotřebovaných čoček nebo zrcadel.

Aktualizace softwaruUdržování řídicího softwaru v aktuálním stavu pro zachování kompatibility a výkonu.

Odborná podpora pro údržbu femtosekundových laserů

Femtosekundové lasery představují vrchol ultrarychlé laserové technologie a poskytují bezkonkurenční přesnost, minimální tepelné poškození a široký aplikační potenciál v různých odvětvích. Jejich pokročilá konstrukce však také znamená, že pro zajištění dlouhé životnosti a konzistentního výkonu je zásadní řádná údržba a odborná podpora.

NaGEEKVALUE, specializujeme se naopravy, údržba a servis špičkových laserových systémů, včetně femtosekundových laserů. Ať už se potýkáte s problémy s nastavením paprsku, nestabilitou pulzu nebo degradací součástí, náš tým zkušených inženýrů je vybaven k tomu, aby vám poskytlrychlá, spolehlivá a cenově výhodná řešeníChápeme naléhavost minimalizace prostojů, a proto nabízíme:

✅ Rychlá diagnostická reakce a opravy na místě

✅ Dodávka a výměna originálních dílů

✅ Dlouhodobé servisní smlouvy a optimalizace výkonu

✅ Technické konzultace pro upgrady a integraci systémů

Pokud používáte nebo plánujete investovat do femtosekundového laserového zařízení, důvěřujte společnosti GEEKVALUE jako spolehlivému poskytovateli poprodejních služeb.Kontaktujte nás ještě dnesa dozvíte se více o tom, jak můžeme podpořit výkon a spolehlivost vašeho laserového systému.