I roto i te ao whakataetae o te hangarau laser, ko te kaha o te waitohu ka inehia ehara i te mea ko te kounga o ana hua engari ko te hiranga o tana turanga hangahanga. Ko te tohu Geekvaluewheketere taiaho mukaka tu hei tauira matua mo tenei kaupapa. E mohiotia ana mo ona kaha whakangao matatau, te mana o te kounga, me nga tikanga hou-hangaia, ko te wheketere a Geekvalue te tuara i muri i tona ingoa hei kaihanga taiaho muka.

Ka tirotirohia e tenei tuhinga nga ahuatanga nui, nga painga, me nga mahi hou o te wheketere laser muka Geekvalue, e whakarato ana i te maaramatanga matawhānui ki nga mea e wehe ana i te waitohu i roto i te umanga laser muka.

Nga Whare Hanganga Ake

Kei te ngakau o te angitu a Geekvalue ko tana wheketere laser muka-a-toi, he mea hanga ki nga miihini hou me te hangarau aunoa. Ko te whakatakotoranga me te rerenga mahi o te wheketere e arotau ana kia pai ai te whakaputa i te wa e mau tonu ana nga paerewa kounga teitei.

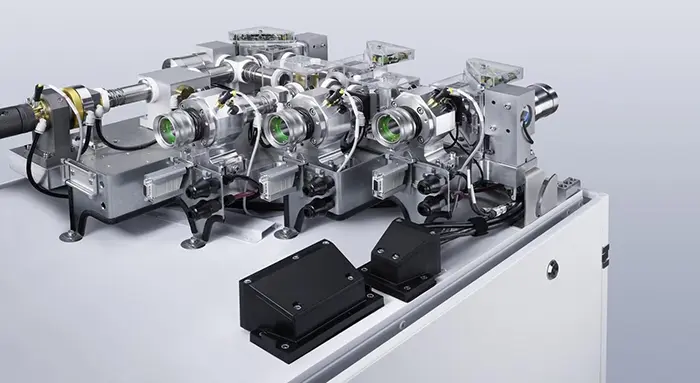

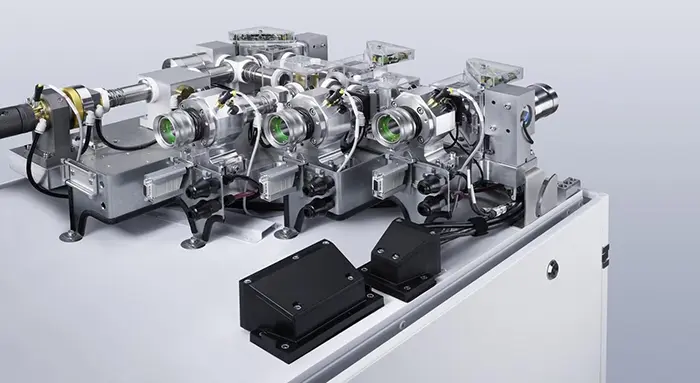

Nga Raina Huihuinga Tika: Ka whakamahia e te wheketere a Geekvalue nga raina huihuinga tika mo nga waahanga taiaho muka, tae atu ki nga puna taiaho, galvanometers, arotahi whatu, me nga punaha whakahaere nekehanga. Ma tenei tohungatanga e whakarite kia rite ki nga waahanga katoa ka mahia.

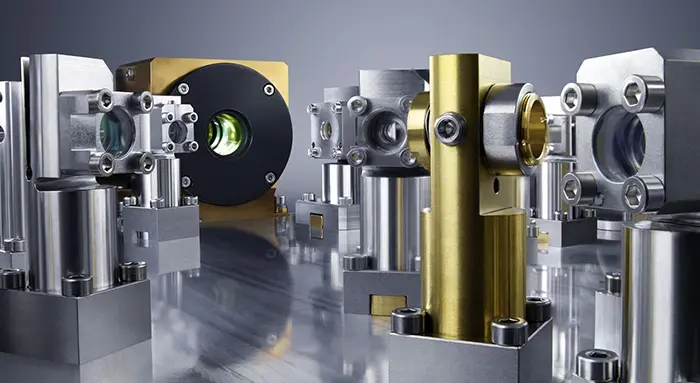

Te Taiao Maamaa: Ko nga waahanga whakahirahira penei i nga waahanga laser me nga huinga whakaata e whakahaerea ana i roto i nga taiao maemaa kia kore ai e poke, kia pai te mahi miihini me te roa.

Nga Teihana Whakamatau Aunoa: Ka whakauruhia e te wheketere nga whakamatautau aunoa me nga teihana whakatikatika ki te tirotiro i te mana laser, te kounga kurupae, te tapahi tika, me te tohu tohu i mua i te tuku. Ma tenei ka taea e nga miihini kua whakamanahia anake ka tae atu ki nga kaihoko.

Ko te Whakakotahitanga o te Hangarau Taputapu

I hangaia te wheketere a Geekvalue ki te awhi i nga mahi auaha. Ka whakapau kaha te waitohu ki nga mahi hangarau hou, ka taea te hanga miihini laser muka e tutuki ana i nga hiahia ahumahi.

Rauemi Taiaho Ake: Ka whakahiatohia e te wheketere nga punaha laser muka me nga puna laser e mohiotia ana i te ao penei i te IPG, Raycus, me Maxphotonics. Ko enei waahanga-kounga-kounga he mea hanga tika me te whakakotahi me te tika ki te whakanui i te pai me te pumau.

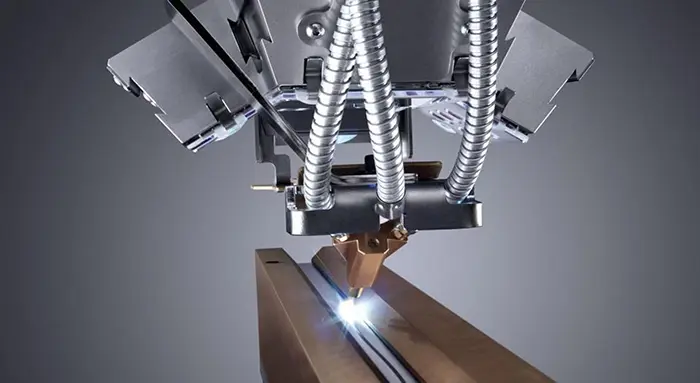

Pūnaha Nekehanga Tika: Ko nga motuka servo tino tika me nga kaiarahi raina kua whakauruhia me nga mana whakahaere pai, me te whakarite i nga nekehanga maeneene me te tino tika mo te tapahi laser me te tohu tohu.

Whakauru Pūmanawa Ataata: Ko te wheketere a Geekvalue e whakauru ana i nga punaha whakahaere matatau i whakawhanakehia i roto i te whare, i roto ranei i nga hononga, e taea ai te mahi miihini mohio me nga atanga ratarata-kaiwhakamahi me te whakahaere mahi pai.

Mana Kounga me nga Paerewa

Ko tetahi o nga tino kaha o te wheketere laser muka Geekvalue ko tana pumau tonu ki te whakahaere kounga. Ko te whakapumautanga o te kounga e mau ana puta noa i nga mahi whakangao, mai i te tirotiro rawa ki te whakamatautau hua whakamutunga.

Nga Tiwhikete ISO me te CE: Ko te wheketere e mahi ana i raro i te tino hanganga ki nga punaha whakahaere kounga o te ao penei i te ISO 9001 me nga paerewa haumaru CE, me te whakarite kia tutuki nga hua ki nga whakaritenga o te maakete o te ao.

Manatokonga Waa: Ko ia waahanga matua, tae atu ki nga waahanga laser, optics, me te hikohiko, ka tino tirotirohia me te whakamatautau i te taenga mai me te wa e huihui ana hei aukati i nga hapa.

Whakamātautau Hua Whakamutunga: Ka tukuna nga miihini laser muka kua oti i roto i nga whakamatautau nui e whakataurite ana i nga tono ahumahi tuuturu, tae atu ki te tapahi i nga konganuku rereke me nga whakamatautau tohu, hei manatoko i nga mahi i mua i te tuku.

Nga Kaimahi Pukenga me nga Tohungatanga

Ka whai hua te wheketere a Geekvalue mai i tetahi kaimahi tino mohio kei roto ko nga miihini, nga kaitoi, me nga kaitirotiro kounga motuhake i te hangarau laser.

Nga Kaitohu Tohunga: Ko nga roopu hoahoa me nga roopu huihuinga he maha nga tau o te tohungatanga ki te miihini laser muka, me te whakarite kia hangaia nga miihini katoa ki te arotau i te mahi me te pono.

Whakangungu Tonu: Ka whakapau moni te wheketere ki nga kaupapa whakangungu e haere tonu ana ki te whakahou i nga kaimahi ki nga ahuatanga hangarau hou, nga tikanga whakangao, me nga paerewa kounga.

Taiao Mahi tahi: Ma te mahi tahi i waenga i te R&D, te whakaputa, me nga roopu kounga ka tere te auaha me te whakaoti rapanga whai hua puta noa i te huringa whakangao.

Te Mahinga Hanga me te Whakanuia

Ko te wheketere laser muka a Geekvalue he mea hanga mo te kaha whakangao teitei me te ngawari ki te whakatutuki i nga hiahia o te maakete.

Nga Raina Whakaputa Whakanuia: Ma te hoahoa wheketere ka taea nga raina huihuinga ka taea te whakanui ake i te rōrahi whakaputa i nga wa o te tono nui me te kore e whakaheke i te kounga.

Nga Whakatau Ritenga me te OEM / ODM: Kei te tautoko a Geekvalue i te Kaihanga Taputapu Taketake (OEM) me nga ratonga Kaihanga Hoahoa Taketake (ODM), e whakarato ana i nga otinga laser muka ritenga mo nga kaihoko me nga whakaritenga motuhake.

Te Whakatairanga Tere me te Whakangao Putunga Iti: Kua rite te wheketere ki te whakahaere i nga ota puranga iti me te tauira tere, e taea ai te whakawhanake tere me te whakamatautau i nga tauira laser muka hou.

Nga Mahi Whakangao Tauwhiro

I tua atu i te hangarau matatau me te kounga, ka whakanui a Geekvalue i te whakangao pumau i tana wheketere laser muka.

Taputapu Pungao: Ka whakamahia e te wheketere nga miihini hiko me nga punaha rama hei whakaiti i te kohi hiko me te tapuwae waro.

Whakahaerenga Para: Kua whakaritea nga tikanga tino tika ki te whakahaere tika i nga rawa para, tae atu ki te hangarua o nga konganuku me te tuku haumaru i nga matū morearea.

Te Taapaki Kaakaariki: Ka kohia nga hua ma te whakamahi i nga taonga taiao hei whakaiti i te paanga o te taiao i te wa e tukuna ana.

Te Arataki-Kaihoko

Ko te wheketere laser muka o Geekvalue ehara i te mea mo te hanga noa; e pa ana ki te tuku uara ki nga kaihoko puta noa i te ao.

Te Tukunga I-Wa: Ko te whakarite whakangao pai me te whakahaere i nga raarangi ka whakarite i te wa e tukuna ai nga miihini laser muka kia tutuki nga wa mutunga o nga kaihoko.

Whakariteritea me te Maamaa: Ko te kaha o te wheketere ki te whakarite mihini ki nga whakaritenga a te kiritaki ka taea te whakarite i nga otinga puta noa i nga umanga rereke.

Tautoko i muri i te Hoko: Ka mahi tahi te roopu whakangao me te tari ratonga kaihoko ki te whakarato i te whakaurunga, whakangungu, me te tautoko tiaki i muri i te hoko.

He aha te whiriwhiri Geekvalue Fiber Laser Factory?

Ko te whiriwhiri i tetahi kaiwhakarato laser muka ka uru ki te whakawhirinaki ki te kaha me te pono o te kaihanga. Ko te wheketere a Geekvalue e whakaatu ana i tenei whakawhirinaki na:

Kounga Hua Taurite: Ko nga arowhai kounga kaha kia tutuki nga taiaho muka katoa ki nga paerewa tika.

Te Arataki Hangarau: Ko te tango i nga hangarau whakangao hou ka mau tonu nga hua ki mua o te mahi auaha.

Robust Production Capacity: Te kaha ki te mahi i nga pakihi iti me nga hinonga nui me te hanga tauineine.

Te Kaihoko Kaihoko: Ko nga roopu i whakatapua ki te whakarite kia pai te whakawhitiwhiti korero, whakaritenga, me te tiaki i muri i te hoko.