Siplace placement machine is an advanced automation equipment widely used in the electronics manufacturing industry. It can efficiently and accurately place

electronic components on PCB boards, improving production efficiency and quality. Before using the Siplace placement machine, it is very important to master

its programming skills. This article will introduce you to the Siplace placement machine programming tutorial in detail.

Step 1: Understand the basic concepts of Siplace placement machine

Before starting programming, we need to understand the basic concepts of Siplace placement machine. Siplace placement machine consists of machine control unit,

placement head, feeder, conveyor belt and other parts. The machine control unit is responsible for controlling the entire placement process. The placement head is

used to accurately place components on the PCB board, the feeder is used to provide components, and the conveyor belt is used to transfer the PCB board to the next workstation.

Step 2: Learn Siplace placement machine programming language

Siplace placement machines use a specific programming language to control their operation. It is very important to learn the Siplace placement machine programming language,

which can help us accurately control the placement process. Siplace placement machine programming language has a certain complexity, but as long as we learn

it step by step and practice it, we can master its skills.

Step 3: Create a patch program

In the Siplace placement machine, the placement program refers to a series of commands and parameters that control the placement process. Creating patch programs

is the core task of our programming. First, we need to determine the order and position of the patches. Then, we can use Siplace's programming language to write

corresponding commands, such as moving the position of the placement head, selecting a suitable feeder, adjusting the downward force of the placement head, etc.

When creating a placement program, the speed, accuracy, and stability of the placement need to be considered to ensure the quality of the placement.

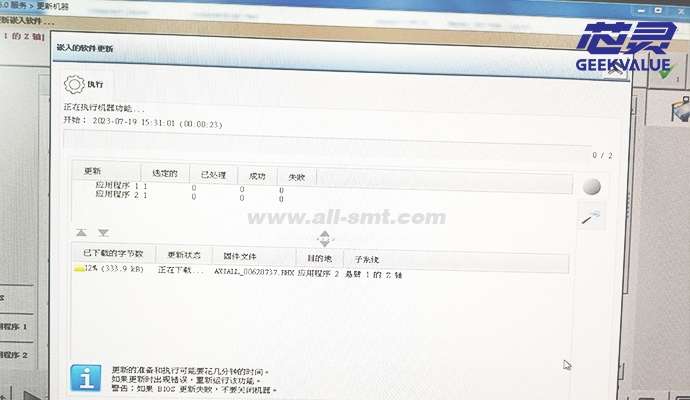

Step 4: Debugging and optimizing the placement program

After creating the patch program, we need to debug and optimize it. First, we can use the simulator to test the operation of the patch program to ensure the correctness

of the program. Then, we can conduct a trial run on the actual Siplace placement machine to observe the effect of placement. If we find errors or unsatisfactory placement,

we can adjust and optimize the program to achieve the best placement effect.

Step 5: Learn the advanced functions of Siplace placement machine

In addition to basic placement functions, Siplace placement machines also have many advanced functions, such as automatic correction, automatic identification of components,

automatic adjustment of the placement head, etc. Learning and mastering these advanced functions can further improve the efficiency and quality of Siplace placement machines.

Siplace placement machine programming is a complex and important task. By learning the basic concepts and programming language of Siplace placement machines,

we can create efficient and accurate placement programs. Debugging and optimizing the placement program are key steps to ensure placement quality. At the same time,

understanding the advanced functions of Siplace placement machines can further improve production efficiency and quality. I hope this article can provide you with

a super-detailed Siplace placement machine programming tutorial to help you achieve greater success in the electronics manufacturing industry.

Finally, if the Siplace placement machine breaks down or parts need to be replaced, be sure to avoid repairing it yourself. The Siplace placement machine is a complex

piece of equipment, and maintenance requires professional knowledge and skills. Doing repairs without permission may cause more serious damage and even pose

a threat to your safety.

Instead, it is recommended that you find a professional maintenance company to handle Siplace placement machine malfunctions and repairs. Xinlingshi is a professional

company with extensive experience and technical expertise that can provide you with high-quality repair services. They understand the working principle and maintenance

process of Siplace placement machines, and can quickly and accurately diagnose and repair faults.

By choosing a professional maintenance company, you can ensure that your Siplace placement machine is properly repaired and maintained, extending its life and keeping

it running efficiently. At the same time, professional maintenance companies can also provide original accessories and warranty services to provide you with all-round support.

Therefore, when the Siplace placement machine fails, be sure to choose a professional maintenance company, such as Xinlingshi, to ensure that your equipment is optimally repaired and maintained.