لیزرهای TRUMPF به دلیل دقت، کارایی و تطبیقپذیریشان در کاربردهای صنعتی مشهور هستند. درک نحوه عملکرد این دستگاههای پیشرفته، بینشی در مورد قابلیتها و مزایای آنها در صنایع مختلف ارائه میدهد.

اصول فناوری لیزر

در هستهلیزر TRUMPFاصل سیستمها، تقویت نور با گسیل القایی تابش (لیزر) است. این فرآیند شامل تولید پرتوی متمرکز از نور با خواص خاص است:

تکرنگیلیزر، نوری با یک طول موج واحد ساطع میکند که باعث تضمین ثبات در تحویل انرژی میشود.

انسجامامواج نور هم فاز هستند و امکان تمرکز و هدایت انرژی را فراهم میکنند.

جهتگیری: پرتو در مسافتهای طولانی باریک باقی میماند و هدفگیری دقیق را ممکن میسازد.

TRUMPF از انواع مختلف لیزر، از جمله لیزرهای حالت جامد و فیبری، استفاده میکند که هر کدام برای کاربردهای خاص طراحی شدهاند.

اجزای کلیدی سیستمهای لیزری TRUMPF

یک دستگاه لیزر TRUMPF شامل چندین جزء حیاتی است که به طور هماهنگ کار میکنند:

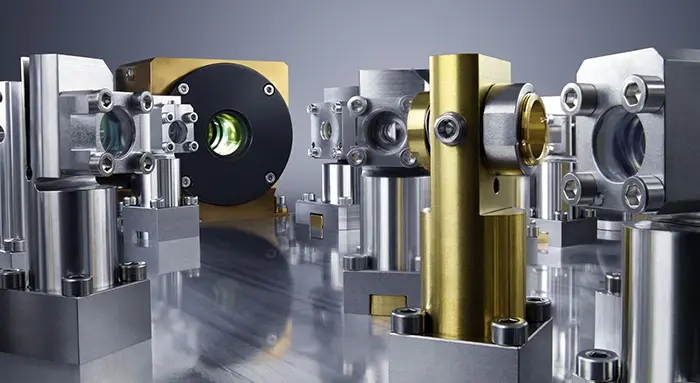

منبع لیزر: پرتو لیزر اولیه را تولید میکند. لیزرهای TruDisk و TruFiber شرکت TRUMPF نمونههایی از این لیزرها هستند که توان و کیفیت پرتو بالایی را ارائه میدهند.

سیستم تحویل پرتو: پرتو لیزر را از منبع به قطعه کار هدایت می کند، که اغلب از آینه ها و فیبر نوری استفاده می کند.

اپتیک متمرکز کنندهلنزها و آینهها پرتو لیزر را در یک نقطه دقیق متمرکز میکنند و چگالی انرژی را برای پردازش مؤثر مواد افزایش میدهند.

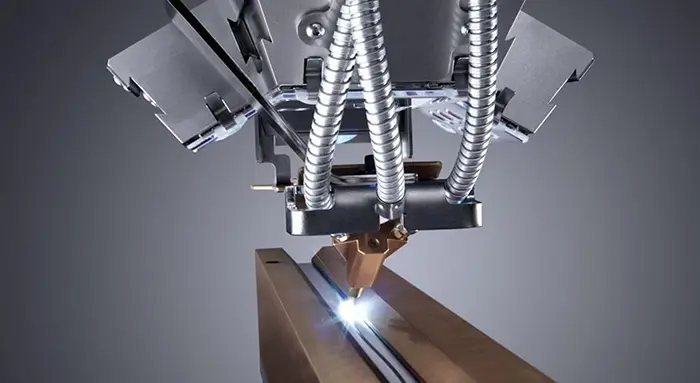

سر برش: محل قرارگیری اپتیکهای متمرکزکننده و نازل است که لیزر و گازهای کمکی را به سمت ماده هدایت میکند.

سیستم گاز کمکیگازهایی مانند اکسیژن یا نیتروژن را برای کمک به برش با حذف مواد مذاب و جلوگیری از اکسیداسیون، آزاد میکند.

واحد کنترل: عملکرد سیستم لیزر، از جمله پارامترهایی مانند قدرت، سرعت و فوکوس را مدیریت میکند.

فرآیند عملیاتی لیزرهای TRUMPF

عملکرد لیزر TRUMPF شامل چندین مرحله است:

تولید پرتو: منبع لیزر پرتویی با شدت بالا تولید میکند.

تحویل پرتو: پرتو از طریق سیستم انتقال به سمت سر برش حرکت میکند.

تمرکز: اپتیک، پرتو را روی قطعه کار متمرکز میکند و چگالی انرژی لازم برای پردازش را به دست میآورد.

برهمکنش موادپرتو متمرکز، ماده را تا نقطه ذوب یا تبخیر گرم میکند و امکان برش، جوشکاری یا علامتگذاری را فراهم میکند.

کاربرد گاز کمکیگازها برای حذف مواد مذاب و محافظت از برش در برابر اکسیداسیون اعمال میشوند.

کنترل حرکتدستگاه، هد لیزر یا قطعه کار را حرکت میدهد تا مسیر برش مورد نظر را با هدایت کنترلهای CNC دنبال کند.

ویژگی های پیشرفته افزایش عملکرد لیزر TRUMPF

TRUMPF چندین فناوری پیشرفته را برای بهینهسازی عملکرد لیزر ادغام میکند:

کنترل سرعت فعال: فرآیند برش را به صورت بلادرنگ رصد میکند و نرخهای تغذیه را برای اطمینان از کیفیت ثابت تنظیم میکند.

قطعات مجهز به RFID: از برچسبهای RFID در لنزها برای ردیابی استفاده و نگهداری استفاده میکند و عملکرد بهینه را تضمین میکند.

اپتیک هوشمندویژگیهایی مانند FocusLine Professional امکان تنظیم خودکار پارامترهای فوکوس را برای مواد و ضخامتهای مختلف فراهم میکند.

پایش وضعیتسیستمهایی مانند TruConnect دادهها را برای نگهداری پیشبینیشده جمعآوری میکنند، زمان از کارافتادگی را کاهش میدهند و بهرهوری را افزایش میدهند.

کاربردها در صنایع مختلف

لیزرهای TRUMPF به دلیل دقت و سازگاریشان در بخشهای مختلفی به کار گرفته میشوند:

خودرو: برش و جوشکاری قطعات با دقت بالا.

هوافضا: ساخت قطعات سبک و با استحکام بالا.

تجهیزات پزشکیتولید قطعات پیچیده و استریل.

الکترونیکمیکروماشینکاری برای بردهای مدار و قطعات.

جواهرات: حکاکی و برش فلزات گرانبها با جزئیات دقیق.

مزایای استفاده از لیزرهای TRUMPF

استفاده از سیستمهای لیزری TRUMPF مزایای متعددی را ارائه میدهد:

دقت: دقت بالایی در برش و حکاکی ایجاد میکند.

کارایی: زمان پردازش و ضایعات مواد را کاهش میدهد.

تطبیق پذیری: قادر به کار با مواد مختلف و طرحهای پیچیده.

اتوماسیون: به طور یکپارچه در خطوط تولید خودکار ادغام میشود.

مقرون به صرفه بودن: هزینه های عملیاتی کمتر در مقایسه با روش های سنتی.

لیزرهای TRUMPF ترکیبی از مهندسی پیشرفته و فناوری نوآورانه هستند و راهکارهایی را ارائه میدهند که فرآیندهای تولید را در صنایع مختلف بهبود میبخشند. عملکرد دقیق آنها، همراه با ویژگیهای هوشمند، نتایج با کیفیت بالا را تضمین میکند و آنها را به یک دارایی ارزشمند در محیطهای تولیدی مدرن تبدیل میکند.