Ніжэй прыведзены поўны агляд датчыка кампанентаў машыны для размяшчэння ASM 03133310, які ахоплівае яго функцыі, характарыстыкі, прымяненне і пункты тэхнічнага абслугоўвання:

1. Асноўны агляд

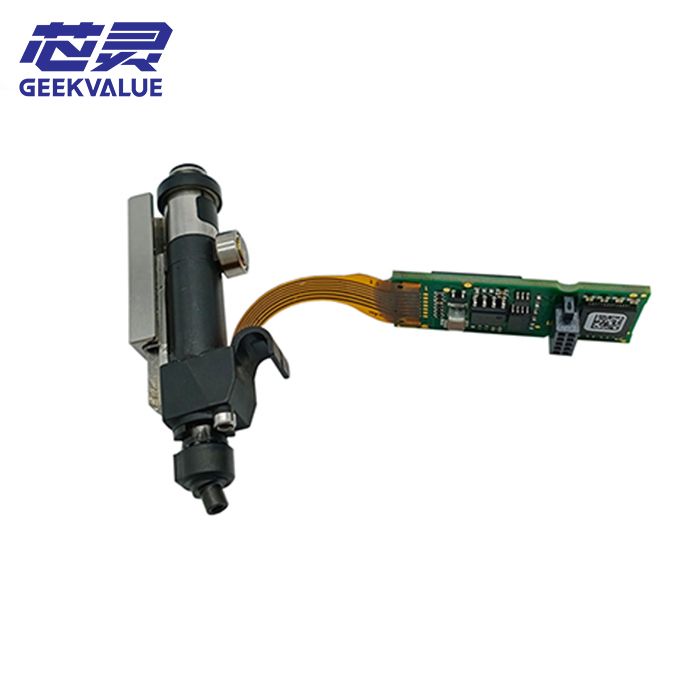

Мадэль: 03133310

Прызначэнне: ключавы датчык у машынах для размяшчэння ASM (напрыклад, серыі SIPLACE ад ASM Pacific Technology), які выкарыстоўваецца для выяўлення наяўнасці, становішча, вышыні або становішча кампанентаў для забеспячэння дакладнасці размяшчэння.

Прыдатнае абсталяванне: Звычайна выкарыстоўваецца ў хуткасных і высокадакладных размяшчальных машынах, такіх як серыя SIPLACE X або больш раннія мадэлі.

2. Асноўныя функцыі

Выяўленне кампанентаў: выкарыстоўвайце аптычную або лазерную тэхналогію, каб вызначыць, ці правільна падняты кампанент, каб пазбегнуць яго прамаху або выкідвання.

Каліброўка пазіцыі: Дапамагае ў карэкцыі каардынат X/Y/Z і вуглавога зрушэння кампанента для павышэння дакладнасці размяшчэння.

Вымярэнне вышыні: вызначэнне таўшчыні кампанента для прадухілення пашкоджанняў, выкліканых няправільным ціскам пры размяшчэнні (напрыклад, расколіны ў стружцы).

Кантроль якасці: выяўленне дэфектаў, такіх як палярнасць кампанентаў і дэфармацыя кантактаў.

3. Тэхнічныя асаблівасці

Высокая дакладнасць: дазвол можа дасягаць мікроннага ўзроўню, падыходзіць для мікракампанентаў, такіх як 0201 і QFN.

Хуткая рэакцыя: хуткасць зваротнай сувязі ў мілісекундах, якая адпавядае хуткасці працы размяшчальнай машыны (напрыклад, 30 000 CPH або больш).

Трываласць: прамысловая канструкцыя, антывібрацыя, пыланепранікальнасць, працяглы тэрмін службы.

Сумяшчальнасць: падтрымлівае розныя тыпы корпусаў (рэзістары, кандэнсатары, мікрасхемы і г.д.) і наладжвальныя параметры для адаптацыі да розных кампанентаў.

4. Сцэнарыі прымянення

Зборка друкаваных плат: вытворчасць дакладных друкаваных плат, такіх як смартфоны, аўтамабільная электроніка і медыцынскае абсталяванне.

Рамонтная станцыя: супрацоўнічаць з размяшчальнай машынай для рамонту дрэнных паяных злучэнняў або замены кампанентаў.

Аўтаматызаваная вытворчая лінія: звязаная з канвеернымі стужкамі і сістэмамі візуалізацыі для дасягнення цалкам аўтаматызаванай вытворчасці.

5. Тэхнічнае абслугоўванне і ліквідацыя непаладак

Агульныя праблемы:

Ілжывая трывога (пыл блакуе аб'ектыў або лазерную галоўку).

Памылка выяўлення (старэнне датчыка або зрушэнне каліброўкі).

Рэкамендацыі па тэхнічным абслугоўванні:

Рэгулярна чысціце аптычныя кампаненты, выкарыстоўвайце ахоўную тканіну і спецыяльныя ачышчальныя сродкі.

Адкалібруйце параметры датчыка, звярніцеся да інструкцыі па эксплуатацыі прылады або да афіцыйнага інструмента ASM.

Праверце падключэнне кабеля, каб пазбегнуць перашкод сігналу.

Этапы замены:

Пасля адключэння харчавання выміце стары датчык.

Усталюйце новы датчык (03133310) і пераканайцеся, што інтэрфейс выраўнаваны.

Пасля ўключэння запусціце праграму каліброўкі.

6. Замена і мадэрнізацыя

Арыгінальная замена: рэкамендуецца аддаваць прыярытэт арыгінальным дэталям ASM для забеспячэння сумяшчальнасці.

Варыянты іншых вытворцаў: некаторыя сумяшчальныя датчыкі могуць быць таннейшымі, але неабходна праверыць адпаведнасць прадукцыйнасці.

Абнаўленне мадэлі: Калі прылада падтрымлівае гэта, вы можаце спытаць у ASM, ці ёсць новае пакаленне датчыкаў (напрыклад, інтэграваная функцыя выяўлення штучнага інтэлекту).

7. Тэхнічныя параметры (прыклад)

Працоўнае напружанне: 24 В пастаяннага току

Дыяпазон выяўлення: 0,1 мм ~ 10 мм (у залежнасці ад канкрэтнай канфігурацыі)

Выхадны сігнал: лічбавы сігнал (TTL/RS-232)

Ступень абароны: IP54 (пыла- і пырскаўабарона)

8. Меры засцярогі

Выконвайце патрабаванні да абароны ад статычнага разраду падчас працы, каб пазбегнуць пашкоджання датчыка статычнай электрычнасцю.

Налады праграмнага забеспячэння павінны адпавядаць апаратнаму забеспячэнню, і абнаўленне прашыўкі можа аптымізаваць прадукцыйнасць.

Калі вам патрэбна больш падрабязная тэхнічная дакументацыя або праверка мадэлі, рэкамендуецца звярнуцца да супрацоўнікаў ASM або ўпаўнаважаных агентаў, каб атрымаць пашпарт 03133310.