The following is a comprehensive introduction to the ASM placement machine component sensor 03133310, covering its functions, features, applications and maintenance points:

1. Basic Overview

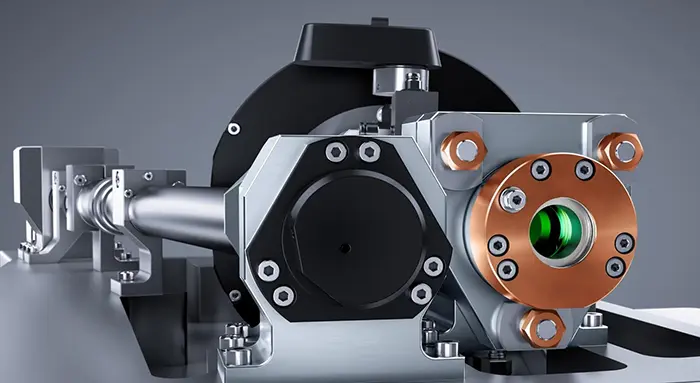

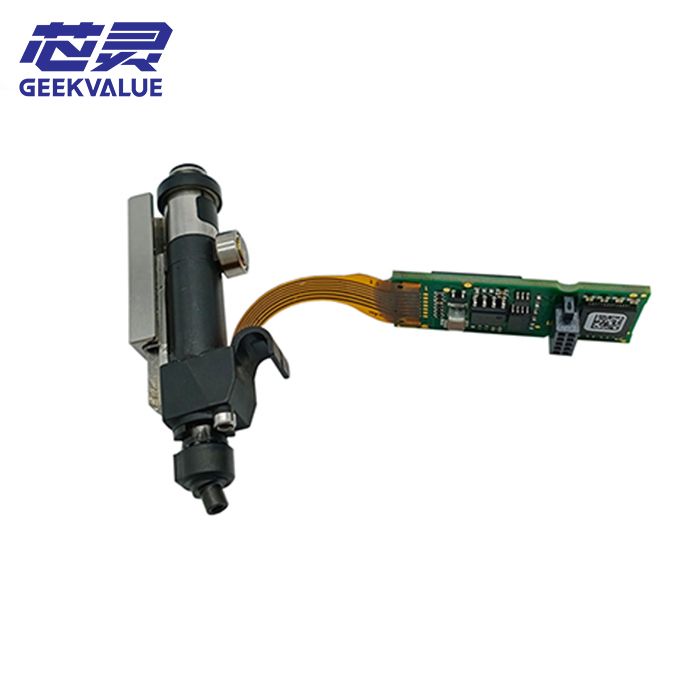

Model: 03133310

Purpose: A key sensor in ASM placement machines (such as ASM Pacific Technology's SIPLACE series) used to detect the presence, position, height or posture of components to ensure placement accuracy.

Applicable equipment: Commonly used in high-speed and high-precision placement machines, such as SIPLACE X series or earlier models.

2. Core functions

Component detection: Use optical or laser technology to identify whether the component is picked up correctly to avoid missing or throwing.

Position calibration: Assist in correcting the X/Y/Z coordinates and angle offset of the component to improve placement accuracy.

Height measurement: Detect component thickness to prevent damage caused by improper placement pressure (such as chip cracking).

Quality control: Identify defects such as component polarity and pin deformation.

3. Technical features

High precision: resolution can reach micron level, suitable for micro components such as 0201 and QFN.

Fast response: millisecond feedback speed, matching the high-speed operation of the placement machine (such as 30,000 CPH or more).

Durability: industrial-grade design, anti-vibration, dust interference, long life.

Compatibility: supports multiple package types (resistors, capacitors, ICs, etc.), and configurable parameters to adapt to different components.

4. Application scenarios

PCB assembly: production of precision circuit boards such as smartphones, automotive electronics, and medical equipment.

Repair station: cooperate with the placement machine to repair bad solder joints or replace components.

Automated production line: linked with conveyor belts and visual systems to achieve fully automated production.

5. Maintenance and troubleshooting

Common problems:

False alarm (dust blocking the lens or laser head).

Detection failure (sensor aging or calibration offset).

Maintenance suggestions:

Regularly clean optical components, use dust-free cloth and special cleaning agents.

Calibrate the sensor parameters, refer to the device manual or ASM official tool.

Check the cable connection to avoid signal interference.

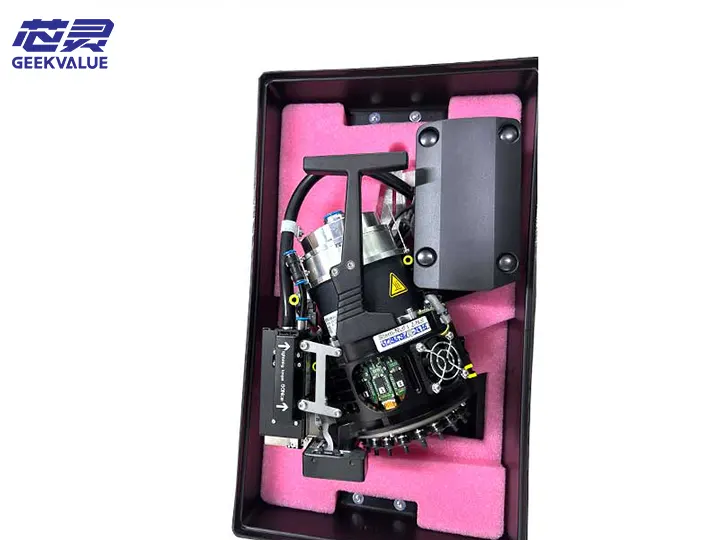

Replacement steps:

Remove the old sensor after power off.

Install the new sensor (03133310) and ensure that the interface is aligned.

Run the calibration program after powering on.

6. Replacement and upgrade

Original replacement: It is recommended to give priority to ASM original parts to ensure compatibility.

Third-party options: Some compatible sensors may be cheaper, but performance matching needs to be verified.

Upgrade model: If the device supports it, you can ask ASM whether there is a new generation of sensors (such as integrated AI detection function).

7. Technical parameters (example)

Operating voltage: 24V DC

Detection range: 0.1mm~10mm (depending on the specific configuration)

Output signal: Digital signal (TTL/RS-232)

Protection level: IP54 (dust and splash proof)

8. Precautions

Follow ESD protection specifications during operation to avoid static electricity damage to the sensor.

The software settings need to match the hardware, and updating the firmware may optimize performance.

If you need more detailed technical documentation or model verification, it is recommended to contact ASM officials or authorized agents to provide the datasheet of 03133310.