Xa abantu becinga ngokusika i-laser, bahlala beyinxulumanisa noyilo oluntsonkothileyo kumaplanga, kwi-acrylic, okanye ephepheni. Nangona kunjalo, umbuzo oqhelekileyo nobalulekileyo uvela:Ngaba aCNC laserukusika isinyithi?Impendulo nguewe—kodwa kukho iinkalo eziliqela ezibalulekileyo. Kweli nqaku, siza kuphonononga ukuba iCNC lasers isebenza njani ngentsimbi, iintlobo zoomatshini ezifanelekileyo, kwaye ngawaphi amashishini axhamlayo kwesi sixhobo.

Yintoni iCNC Laser Cutting?

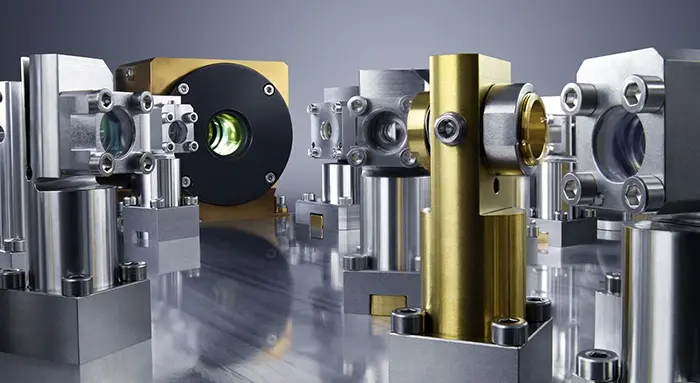

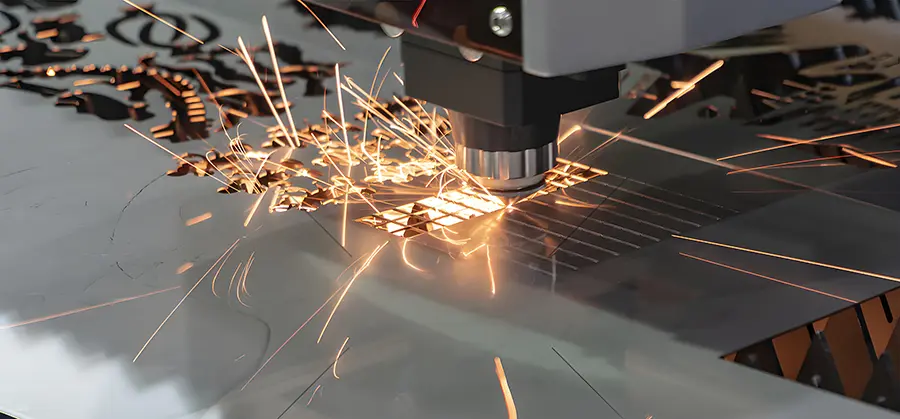

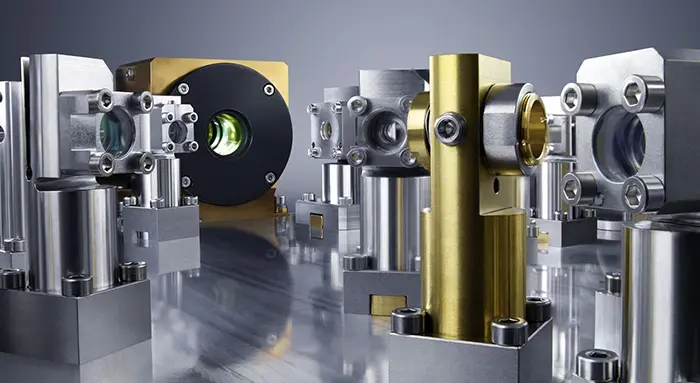

I-CNC laser cutting ibhekisela kwinkqubo yokusebenzisa i-laser beam elawulwa yikhompyutheni ukusika izinto eziphathekayo kwiimilo ezithile okanye ukuyila. Inkqubo ye-CNC itolika iifayile zoyilo kwaye iqondise ngokuchanekileyo intloko ye-laser phezu kwendawo yokusebenza. Umqadi welaser ogxininisiweyo uyanyibilika, utshise, okanye ufuze izinto, uvumele ukusikwa okucocekileyo nokuchanekileyo.

Ngaba iCNC Laser Sika iMetal?

Ewe,I-CNC lasers inokusika isinyithi—kodwa asingabo bonke oomatshini belaser abenzelwe ukuphatha isinyithi. Isakhono sixhomekeke koku:

Amandla eLaser: Ukusika ngesinyithi kufuna i-laser ephezulu yamanzi, ngokuqhelekileyo ifayibha okanyeCO2 lasersubuncinci be-1000 watts amandla.

Uhlobo lweLaser: Iifayibha laserszilungele ukusika isinyithi ngenxa yezinga eliphezulu lokufunxa kwisinyithi kunye nokusebenza kakuhle.

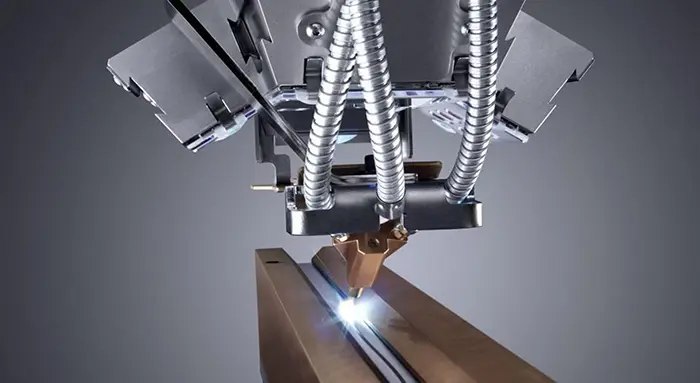

Ukutyeba kwezinto eziphathekayo: Iintsimbi ezityebileyo zifuna iilaser ezinamandla ngakumbi kunye nezantya zokusika ezicothayo.

Iigesi zokuncedisa: Iigesi ezifana neoksijini okanye initrogen zihlala zisetyenziselwa ukunceda inkqubo yokusika kunye nokuphucula umgangatho wecala.

Iintlobo zeMetal zifanelekile ukusika iLaser

1. Intsimbi engatyiwa

Insimbi engenasici isetyenziswa kakhulu kulwakhiwo, izixhobo zonyango, kunye nezicelo zokuhombisa. Ukusika kwe-laser ye-CNC kubonelela ngemiphetho ecocekileyo, engena-burr elungele ukwenziwa ngokuchanekileyo.

2. Intsimbi yeCarbon

Intsimbi yekhabhoni yenye intsimbi eqhelekileyo yokusikwa ngeelaser ze-CNC. Iphendula kakuhle kwi-laser cutting, ngakumbi xa incediswa yi-oksijeni, ephakamisa amandla okusikwa.

3. Aluminiyam

Nangona ibonakalisa kwaye kunzima ukuyisika, ialuminiyam inokusetyenzwa ngeelaser zefiber ezinamandla aphezulu. Isetyenziswa rhoqo kwimizi-mveliso yeemoto kunye ne-aerospace.

4. Ubhedu kunye neBrass

Izinyithi ezibonisa kakhulu njengobhedu kunye nobhedu zifuna iilaser ezikhethekileyo ezinepropathi ezichasayo kunye namandla aphezulu aphezulu.

Izinto ezilungileyo zeCNC Laser Cutting Metal

Ukuchaneka

Ukusikwa kweLaser kunika ukuchaneka okukhethekileyo, nakumashiti esinyithi acekethekileyo nabuthathaka.

Isantya

Ukusika ngesantya esiphezulu kunciphisa amaxesha okucutshungulwa, okubaluleke kakhulu kwimveliso yomgangatho weshishini.

Ukuba bhetyebhetye

Nokuba usika iiprototypes okanye uqhuba imveliso epheleleyo, iinkqubo ze-CNC laser zinokutshintsha ukusuka kuyilo olunye ukuya kolunye kunye nexesha elincinci lokuphumla.

Coca Cuts

Ukutshisa okuncinci kuthetha ukunciphisa emva kokulungiswa, ukonga ixesha kunye neendleko zomsebenzi.

Imida yeCNC Laser Metal Cutting

Iindleko zokuqala: Oomatshini belaser abanamandla aphezulu bayabiza.

Ukutya umbane: Ukubaleka iilaser zefiber kwindawo epheleleyo kufuna umbane obalulekileyo.

Imiqathango yezinto eziphathekayo: Ezinye iintsimbi zinzima ukusika ngaphandle kohlobo oluchanekileyo lwelaser kunye neeparamitha.

Amashishini Asebenzisa CNC Laser Metal Cutting

Iimoto: Ukusuka kwiinkqubo zokukhupha ukuya kwiipaneli zomzimba.

I-Aerospace: Amacandelo esinyithi alula, anamandla aphezulu.

Ezombane: Iingxenye zetsimbi ezichanekileyo zokusikwa kwi-circuitry.

Izixhobo zonyango: Izixhobo zotyando kunye nezixhobo.

Ke, ngaba iCNC laser yokusika isinyithi? Ngokuqinisekileyo. Ngezixhobo ezifanelekileyo kunye nokusekwa, ukusika kwe-laser yensimbi kuba sisisombululo esinamandla kubavelisi kuluhlu olubanzi lwamashishini. Ukusuka kwintsimbi engatyiwayo ukuya kwi-aluminiyam, iinkqubo zeCNC laser ziyakwazi ukuguqula isinyithi ekrwada zibe ngamacandelo esikwe ngokuchanekileyo, alungele ukusetyenziswa.