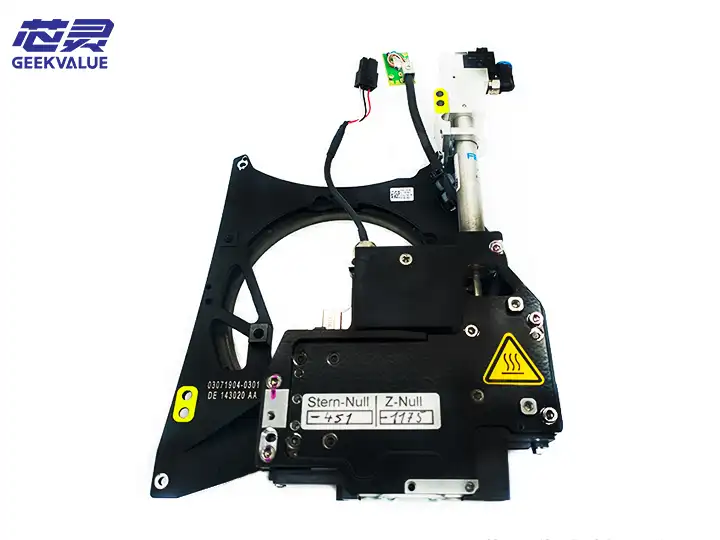

ASM SMT 2X8MM Feeder (Model 00141289) ເປັນອຸປະກອນການໃຫ້ອາຫານອົງປະກອບເອເລັກໂຕຣນິກສໍາລັບສາຍການຜະລິດ SMT. ຫຼັກການການເຮັດວຽກຂອງມັນແມ່ນອີງໃສ່:

ຂັບເຄື່ອນດ້ວຍໄຟຟ້າ, ສາຍແອວວັດສະດຸແມ່ນກ້າວຫນ້າໂດຍມໍເຕີ stepper ທີ່ຊັດເຈນ

ເຊັນເຊີກວດຫາຕໍາແຫນ່ງອົງປະກອບແລະສະຖານະການໃຫ້ອາຫານ

ໂຄງສ້າງກົນຈັກຮັບຮູ້ການຈັດຕໍາແຫນ່ງທີ່ຖືກຕ້ອງແລະການໃຫ້ອາຫານຂອງ tape carrier ກວ້າງ 8mm

ການອອກແບບ dual-channel (2X) ສາມາດຈັດການສອງມ້ວນຂອງອົງປະກອບໃນເວລາດຽວກັນ, ປັບປຸງປະສິດທິພາບການຜະລິດ.

II. ຄຸນສົມບັດຜະລິດຕະພັນ

ຄຸນນະສົມບັດໂຄງສ້າງກົນຈັກ:

ການອອກແບບກະທັດຮັດ, ປະຫຍັດພື້ນທີ່ການຜະລິດ

ໂຄງປະກອບການແບບໂມດູນ, ການບໍາລຸງຮັກສາງ່າຍແລະການທົດແທນຂອງພາກສ່ວນ

ລາງລົດໄຟຄູ່ມືຄວາມຖືກຕ້ອງຮັບປະກັນຄວາມຫມັ້ນຄົງຂອງການໃຫ້ອາຫານ

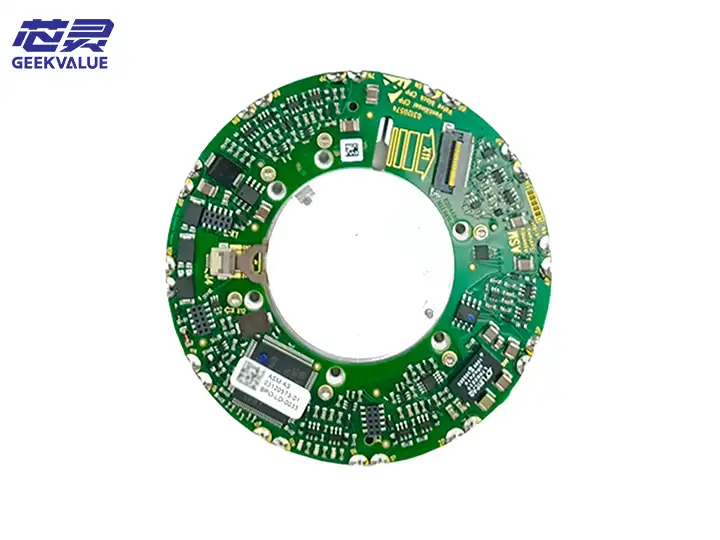

ຄຸນນະສົມບັດໄຟຟ້າ:

ເຊັນເຊີ photoelectric ຄວາມແມ່ນຍໍາສູງກວດພົບຕໍາແຫນ່ງອົງປະກອບ

ໂປຣແກຣມຄວບຄຸມຄວາມຍາວຂັ້ນຕອນການໃຫ້ອາຫານ

ດ້ວຍການທໍາງານການວິນິດໄສຕົນເອງ

ຄຸນນະສົມບັດການດໍາເນີນງານ:

ການໂຕ້ຕອບການດໍາເນີນງານຂອງມະນຸດ

ການທົດແທນໄວຂອງການອອກແບບ tape carrier

ເຂົ້າກັນໄດ້ກັບຄວາມຫລາກຫລາຍຂອງອົງປະກອບຫຸ້ມຫໍ່ 8mm

III. ຄຸນນະສົມບັດຜະລິດຕະພັນໄດ້ປຽບຜະລິດຕະພັນ

ປະສິດທິພາບສູງ:

ການອອກແບບສອງຊ່ອງເພື່ອປັບປຸງຄວາມໄວການໃຫ້ອາຫານ

ເວລາຕອບສະໜອງໄວ (<100ms)

ຄວາມແມ່ນຍໍາສູງ:

ຄວາມຖືກຕ້ອງຂອງການໃຫ້ອາຫານສາມາດບັນລຸ ± 0.05mm

ຄວາມສາມາດເຮັດເລື້ມຄືນສູງ:

ຄວາມຫນ້າເຊື່ອຖືສູງ:

ເວລາສະເລ່ຍລະຫວ່າງຄວາມລົ້ມເຫລວ (MTBF)> 10,000 ຊົ່ວໂມງ

ວັດສະດຸທີ່ມີຄຸນນະພາບສູງເພື່ອຮັບປະກັນການດໍາເນີນງານທີ່ຫມັ້ນຄົງໃນໄລຍະຍາວ

ຄວາມເຂົ້າກັນໄດ້:

ຮອງຮັບເຄື່ອງບັນທຸກກວ້າງ 8 ມມ

ເຂົ້າກັນໄດ້ກັບເຄື່ອງຈັດວາງ ASM ຕ່າງໆ

IV. ຂໍ້ຄວນລະວັງສໍາລັບການນໍາໃຊ້

ຂໍ້ຄວນລະວັງການຕິດຕັ້ງ:

ໃຫ້ແນ່ໃຈວ່າຕົວປ້ອນຂໍ້ມູນ ແລະສ່ວນຕິດຕໍ່ຂອງເຄື່ອງຈັດວາງເຊື່ອມຕໍ່ຢ່າງຖືກຕ້ອງ

ກວດເບິ່ງວ່າການເຊື່ອມຕໍ່ໄຟຟ້າແມ່ນແຫນ້ນ

ຢືນຢັນວ່າສາຍດິນແມ່ນດີ

ຂໍ້ຄວນລະວັງການດໍາເນີນງານ:

ກ່ອນທີ່ຈະຕິດຕັ້ງຜູ້ຂົນສົ່ງ, ກະລຸນາກວດເບິ່ງວ່າຜູ້ໃຫ້ບໍລິການມີຮູບຮ່າງຜິດປົກກະຕິຫຼືເສຍຫາຍ

ໃຫ້ແນ່ໃຈວ່າໄລຍະຫ່າງອົງປະກອບຖືກຕັ້ງຢ່າງຖືກຕ້ອງ

ຫຼີກເວັ້ນການປະຕິບັດການ overload

ຂໍ້ຄວນລະວັງຄວາມປອດໄພ:

ກະລຸນາປິດໄຟສໍາລັບການບໍາລຸງຮັກສາກ່ອນທີ່ຈະດໍາເນີນການ

ຢ່າບັງຄັບເອົາອົງປະກອບອອກໃນລະຫວ່າງການປະຕິບັດງານ

ຮັກສາພື້ນທີ່ເຮັດວຽກໃຫ້ສະອາດ

V. ຂໍ້ຄວາມຜິດພາດທົ່ວໄປແລະການແກ້ໄຂ

ລະຫັດຄວາມຜິດພາດ ຄໍາອະທິບາຍຄວາມຜິດພາດ ສາເຫດທີ່ເປັນໄປໄດ້ ການແກ້ໄຂ

E001 ຄວາມລົ້ມເຫຼວຂອງການໃຫ້ອາຫານ ຜູ້ໃຫ້ບໍລິການຕິດຢູ່/ຄວາມລົ້ມເຫຼວຂອງເຄື່ອງຈັກ ກວດເບິ່ງເສັ້ນທາງຂອງຜູ້ໃຫ້ບໍລິການ/ອຸປະກອນຣີສະຕາດ

ເຊັນເຊີ E002 ຄວາມຜິດປົກກະຕິຂອງເຊັນເຊີ Photoelectric ເປື້ອນ/ເສຍຫາຍ ເຊັນເຊີສະອາດ/ປ່ຽນເຊັນເຊີ

E003 ການສື່ສານຜິດພາດສາຍການເຊື່ອມຕໍ່ວ່າງ / ການເຊື່ອມຕໍ່ຄວາມລົ້ມເຫຼວ ກວດສອບການເຊື່ອມຕໍ່ / ທົດແທນສາຍການເຊື່ອມຕໍ່

ຂໍ້ຜິດພາດ E004 Timeout ຄວາມຕ້ານທານການໃຫ້ອາຫານມີຂະຫນາດໃຫຍ່ເກີນໄປ ກວດເບິ່ງຄວາມເຄັ່ງຕຶງຂອງສາຍສົ່ງ / ທໍ່ນໍ້າມັນທີ່ແນະນໍາ

E005 ການບ່ຽງເບນຕໍາແຫນ່ງໂຄງສ້າງກົນຈັກວ່າງ ກວດເບິ່ງແລະຮັດພາກສ່ວນທີ່ກ່ຽວຂ້ອງ

VI. ວິທີການບໍາລຸງຮັກສາ

ບໍາລຸງຮັກສາປະຈໍາວັນ:

ເຮັດຄວາມສະອາດພື້ນຜິວແລະນໍາພາທາງລົດໄຟຂອງ feeder ປະຈໍາວັນ

ກວດເບິ່ງວ່າເຊັນເຊີສະອາດຫຼືບໍ່

ຢືນຢັນວ່າ fasteners ທັງຫມົດແມ່ນບໍ່ວ່າງ

ການບໍາລຸງຮັກສາປົກກະຕິ:

ຕື່ມນໍ້າມັນໃສ່ຊິ້ນສ່ວນທີ່ເຄື່ອນຍ້າຍທຸກໆເດືອນ (ໃຊ້ນໍ້າມັນທີ່ລະບຸໄວ້)

ກວດເບິ່ງສະຖານະມໍເຕີທຸກໆໄຕມາດ

ປະຕິບັດການສອບທຽບເຕັມທຸກໆຫົກເດືອນ

ຂໍ້ແນະນຳການເກັບຮັກສາໄລຍະຍາວ:

ເກັບຮັກສາໃນສະພາບແວດລ້ອມແຫ້ງຫຼັງຈາກການທໍາຄວາມສະອາດ

ເປີດເຄື່ອງເປັນປະຈຳເພື່ອປ້ອງກັນການແກ່ຂອງວົງຈອນ

ນໍາໃຊ້ນ້ໍາມັນຕ້ານ rust ກັບພາກສ່ວນທີ່ສໍາຄັນ

ຮອບວຽນການທົດແທນສ່ວນທີ່ສວມໃສ່:

ເຄື່ອງມືການໃຫ້ອາຫານ: ປະມານ 500,000 ເທື່ອ

ເຊັນເຊີ Photoelectric: ປະມານ 2 ປີຫຼືຂຶ້ນກັບການນໍາໃຊ້ແມ່ນຂຶ້ນກັບ

ອົງປະກອບຂອງສາຍສົ່ງ: ປະມານ 1 ປີຫຼືຂຶ້ນກັບການສວມໃສ່ແລະ tear

VII. ຕົວກໍານົດການດ້ານວິຊາການ

ແບບ: 00141289

ຄວາມກວ້າງຂອງສາຍສົ່ງ: 8mm

ຈໍານວນຊ່ອງ: 2

ຄວາມຖືກຕ້ອງຂອງການໃຫ້ອາຫານ: ± 0.05mm

ຄວາມໄວການໃຫ້ອາຫານສູງສຸດ: 300 ອົງປະກອບ/ນາທີ (ຕໍ່ຊ່ອງ)

ຄວາມຕ້ອງການພະລັງງານ: 24VDC ± 10%

ການບໍລິໂພກພະລັງງານ: <50W

ອຸນຫະພູມການເຮັດວຽກ: 15-35°C

ອຸນຫະພູມການເກັບຮັກສາ: -10-60°C

ນ້ໍາຫນັກ: ປະມານ 2.5kg

ຂະໜາດ: 150×80×60ມມ (ຍາວ×ກວ້າງ×ສູງ)

ໂດຍຜ່ານການນໍາໃຊ້ແລະການບໍາລຸງຮັກສາທີ່ເຫມາະສົມ, ASM 2X8MM feeder 00141289 ສາມາດສະຫນອງການສະຫນອງທີ່ຫມັ້ນຄົງແລະເຊື່ອຖືໄດ້ຂອງອົງປະກອບສໍາລັບສາຍການຜະລິດ SMT, ປັບປຸງປະສິດທິພາບການຜະລິດແລະຄຸນນະພາບຂອງຜະລິດຕະພັນຢ່າງຫຼວງຫຼາຍ.