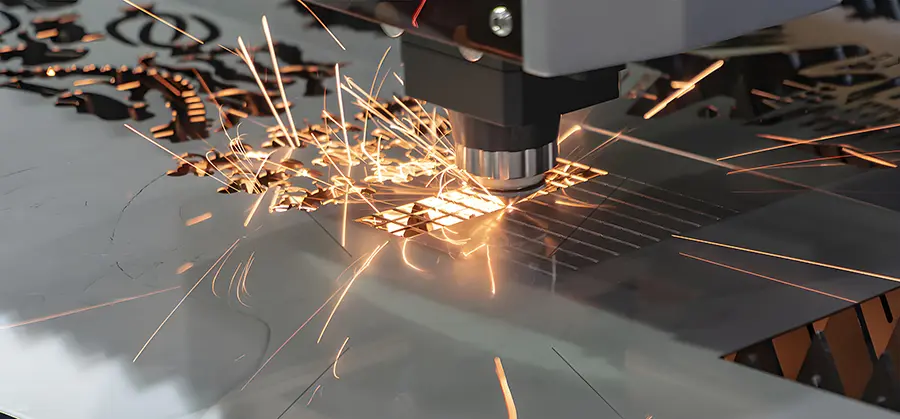

What is CNC Laser?

CNC Laser (Computer Numerical Control Laser) is an industrial technology that uses a numerical control system to control the laser head for high-precision cutting, engraving and marking. Compared with traditional mechanical processing, CNC laser has:

Higher precision and repeatability

Non-contact processing reduces material loss

Can process a variety of materials such as metal, plastic, acrylic, wood, etc.

More suitable for complex graphics and high-efficiency mass production

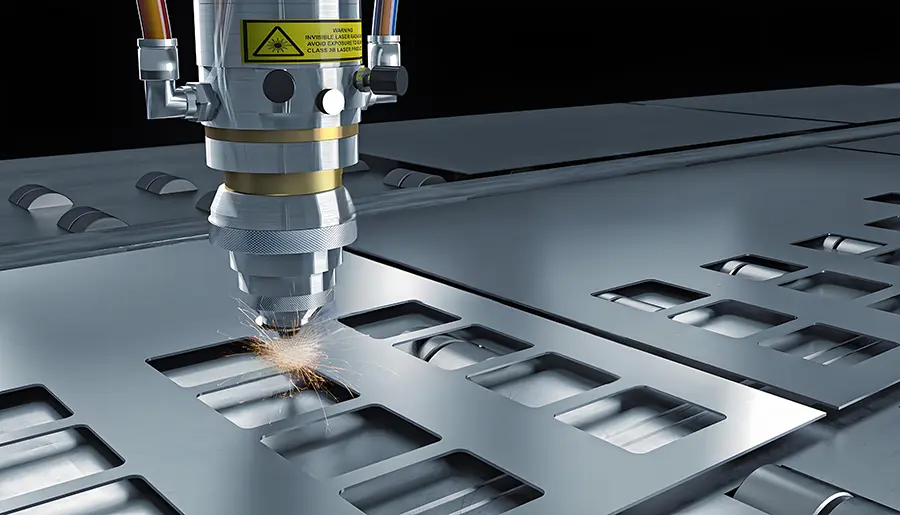

How CNC Laser Works

A CNC laser machine operates by focusing a high-powered laser beam onto the material surface, controlled via software to execute detailed designs. Key components include:

Laser Source (CO₂, Fiber, YAG)

CNC Controller

Laser Head & Optics

Cooling and Ventilation Systems

Laser Repair & Maintenance Services

Need expert support for your CNC laser machine? We provide professional repair and preventive maintenance services to keep your equipment running at peak performance. Whether you're experiencing laser misalignment, software errors, or power issues, our experienced technicians are ready to help—fast and reliably.

-

Laser Tube Replacement & Alignment

Over time, laser tubes degrade and lose power. We provide fast replacement services with high-quality tubes and ensure precise beam alignment for optimal performance and cutting accuracy.

-

Controller and Software Troubleshooting

Facing software crashes or unexpected machine behavior? Our technicians specialize in diagnosing controller issues, firmware errors, and compatibility problems with your CNC laser's software.

-

Mirror and Lens Cleaning or Replacement

Dirty or damaged optics can drastically reduce laser efficiency. We offer professional cleaning, inspection, and replacement of mirrors and lenses to restore full cutting power.

-

Cooling System Inspection & Repair

Dirty or damaged optics can drastically reduce laser efficiency. We offer professional cleaning, inspection, and replacement of mirrors and lenses to restore full cutting power.

-

Preventive Maintenance Plans

Prevent breakdowns before they happen. Our scheduled maintenance plans include mechanical checks, cleaning, calibration, and performance diagnostics tailored to your machine's usage.

-

On-site & Remote Technical Support

No matter where you're located, our support team is ready to help. We offer both on-site service and remote assistance via phone, video, or remote desktop to resolve issues quickly.

Why Choose Me To Be Your Permanent Partner?

“It’s not just a repair, it’s also a rebirth of the device into a ‘high-end version’.

Our mission is to integrate upstream and downstream industry resources and work hand in hand with industry experts to create a professional and efficient engineer service team. Adhering to the concept of "helping every customer reduce costs and increase efficiency", we use the dual-chain model of "supply chain + technology chain" to create an intelligent ecosystem and provide worry-free pre-sales and after-sales services for the global laser equipment industry.

As a leader in one-stop laser solutions, we have long insisted on empowering technological innovation with excellent technology and efficient services.

-

Original factory level technical team

▶ Senior engineers with 20+ years on site are proficient in the core principles of mainstream brand lasers such as IPG/TRUMPF/Coherent/Racus/Chuangxin, and can accurately diagnose the root cause of faults.

-

Full process precision repair

▶ From optical module calibration, control board chip-level repair, resonant cavity debugging to power curve optimization, ensure that the performance after repair is ≥ factory standard.

-

Ultra-fast response + data-based operation and maintenance

▶ Day and night shift operation, 24-hour emergency support, IoT remote pre-fault detection, and maintenance timeliness increased by 50% compared with the industry average.

-

Spare parts supply chain assurance

▶ Original certified spare parts library (control board/laser tube/galvanometer/QBH head) to eliminate compatibility risks and extend service life by 30%.

-

Process value-added services

▶ Free laser parameter tuning solutions are provided, and the output power stability is improved to ±1.5% (industry ±3%).

Comparison of CNC Laser Types

| Type | Materials | Features | Cost |

|---|---|---|---|

| CO₂ Laser | Wood, Plastic, Leather | Fast cutting, non-metal focus | Low |

| Fiber Laser | Metals | High precision, low energy use | Medium to High |

| YAG Laser | Metal Surface | Mainly for marking | Medium |

Buying Guide: Choosing the Right CNC Laser

Match material type and thickness with suitable laser power

Check required precision and speed

Ensure good after-sales support

Software compatibility with your workflow

Choose a reputable brand (e.g., Trotec, Epilog, HSG, Han's Laser)

CNC Laser Repair and Maintenance Guide

-

29

2025-05

Ultimate Guide to Laser Repair: Troubleshooting Power FluctuationsPower instability in laser equipment isn’t just an annoyance—it can bring production to a halt, compromise precision, an...

-

29

2025-05

Lumenis Medical Aesthetic Laser RepairEquipment cleaning: Regularly use a clean, soft, lint-free cloth to wipe the device housing to remove surface dust and s...

-

29

2025-05

Innolume Fiber Laser Bragg-GratingInnolume's Fiber Bragg Grating (FBG) is an important optical device based on the principle of fiber optics

-

29

2025-05

Innolume solid-state fiber laser (BA)Innolume's Broad Area Lasers (BA) play a key role in many fields as multimode light sources. They can provide high ...

-

29

2025-05

ASYS Industrial Laser 6000 SeriesASYS Laser is an important brand of ASYS Group that focuses on laser marking technology. It has been widely used in many...

CNC laser FAQ

-

Can a CNC Laser Cut Metal?

Can a CNC laser cut metal? The answer is yes—but with several important considerations. In this article, we’ll explore h...

-

What is a CNC Laser?

In the modern era of digital manufacturing and high-precision fabrication, CNC laser machines have revolutionized how we...

-

How Long Does a CNC Laser Last?

CNC laser machines are a cornerstone of modern manufacturing, known for their precision, speed, and versatility. One of ...