Recently, many customers asked us how to choose the feeder model and how to configure the number of feeders? Today, Geekvalue will show you how to choose the feeder

model and how to configure the number of feeders for Siemens placement machines, hoping to give you some reference.

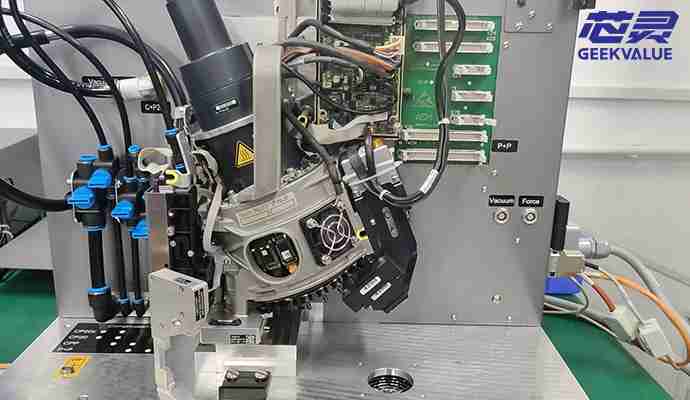

What is Siemens placement machine feeder?

The function of the placement machine feeder is to provide the SMD component mounted on the feeder to the placement machine for placement.

Mounter feeders mainly include cassette feeders, belt feeders, tube feeders, and tray feeders.

The Siemens chip mounter generation feeder is mainly a belt feeder, and the basic width is 4mm, 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 72mm, etc. The width of the

feeder of the Siemens placement machine is a multiple of 4, mainly because the distance between the two vertices of the outer ring of the feeder gear and the hole spacing of the tape are both 4mm.

How to choose Siemens placement machine feeder model

The selection of Siemens placement machine feeder model mainly considers the following factors:

Width of Siemens placement machine feeder: The width of the feeder should be consistent with the width of the packaging material tape of the material. It's like serving 1 person's

meal in a bowl, 4 people's meal in a pot, and 60 people's meal in a bucket. 4mm material corresponds to 4mm feeder, and 16mm material corresponds to 16mm feeder. The number of pitch materials

on the bill of materials depends on the number of feeder models corresponding to the width to be selected.

Feeding speed of Siemens placement machine feeder: Siemens placement machine feeder mainly has two types: X feeder and smart feeder. Compared with x feeder, smart feeder has faster

and more stable feeding speed, more convenient use, and better internal structure.

The price of Siemens placement machine feeder: Based on the price factor, the main consideration is to choose a second-hand or a new feeder. Compared with the new feeder, the price of the

second-hand feeder is cheaper, and you can buy the feeder with the same function at a more affordable price.

How to configure the feeder quantity of Siemens placement machine?

After confirming the Siemens placement machine feeder model, the second thing to consider is the configuration quantity of the feeder.

The configuration quantity of the feeder affects the production efficiency and cost of the factory. The number of feeders that can be accommodated in a placement machine is limited. If only a small

amount of 4mm material needs to be placed, but a large number of 4mm feeders are configured, it will not only occupy the feeding position and increase the frequency of refueling, but also reduce

production efficiency and increase time and money costs. If a large amount of 4mm materials needs to be placed, but only a small amount of 4mm feeders are equipped, some placement machines

will have waiting time, which will also reduce production efficiency and increase time and money costs.

When configuring the number of feeders for Siemens placement machines, factors such as the ratio of materials at each pitch, frequency of refueling, material preparation, number of off-line feeders,

and number of placement machines should be considered to reduce waiting time, achieve rapid line change, and increase material supply speed.

Siemens placement machine feeder configuration seems simple, but in fact it is very particular. Every factory has its individual and diversified needs. When configuring the number of feeders of

Siemens placement machines, all factors must be considered comprehensively to avoid detours. If you are interested in leading and competitive solutions in terms of technology, quality, cost, etc.,

please feel free to contact us to create a better future hand in hand!