What Is a Fiber Laser? A fiber laser is a type of solid-state laser in which the active gain medium is an optical fiber doped with rare-earth elements, most commonly ytterbium. Unlike traditional gas or CO₂ lasers, fiber lasers generate, amplify, and guide light entirely within a glass fiber, resulting in a compact, robust, and highly efficient system.

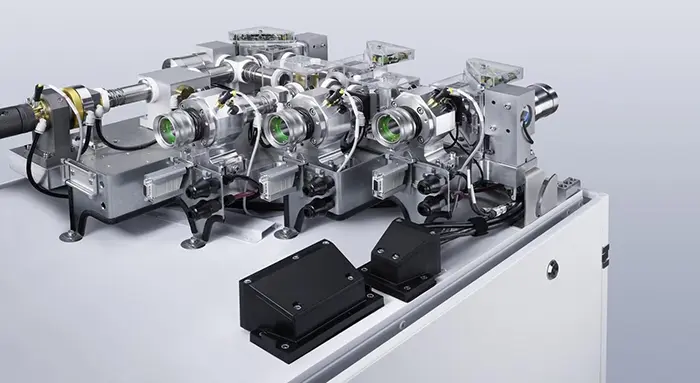

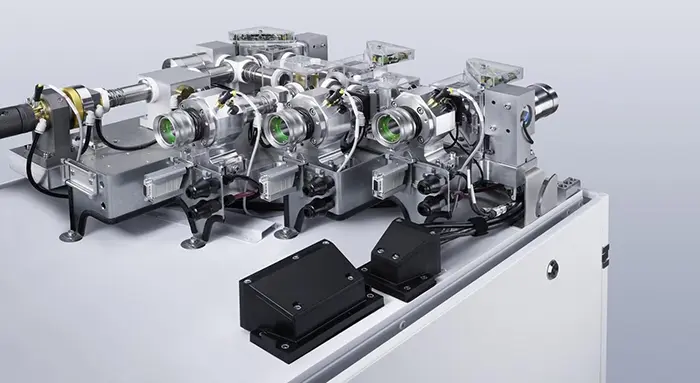

Fiber Laser Core Components and Design

Doped Fiber Core

The heart of a fiber laser is the fiber itself—an ultra-thin strand of glass whose core is infused with rare-earth ions. When pumped with light, these ions provide the energy needed for laser action.Pump Diodes

High-power semiconductor diodes inject pump light into the fiber’s cladding. The cladding traps the pump light around the core, ensuring uniform excitation of the doped ions.Fiber Bragg Gratings (FBGs)

Inscribed directly into the fiber, these reflective gratings form the laser cavity. One grating reflects most of the light back into the fiber, while the other allows a controlled portion to exit as the output beam.Heat Management

Since the fiber’s small cross-section dissipates heat efficiently along its length, fiber lasers typically require only air-cooling or modest water circulation, even at high power levels.

Operating Principle

Optical Pumping

Pump diodes inject light, usually at wavelengths between 915 nm and 976 nm, into the fiber’s cladding.Energy Absorption

Rare-earth ions in the core absorb pump photons, moving electrons to excited states.Stimulated Emission

As electrons relax, they emit coherent photons at the laser’s characteristic wavelength (commonly 1,064 nm).Amplification & Feedback

Photons travel along the fiber, triggering further emissions and amplifying the beam. FBGs at each end of the fiber form a resonant cavity, sustaining laser oscillation.Output Coupling

A partially reflective grating allows a fraction of the amplified light to exit as the high-quality output beam used for processing.

Types of Fiber Lasers

Continuous-Wave (CW) Fiber Lasers

Emit a steady, uninterrupted beam. Ideal for cutting, welding, and marking applications where constant power is required.Pulsed Fiber Lasers

Deliver light in controlled bursts. Subcategories include:Q-Switched: High-peak pulses (nanosecond range) for deep engraving and micro-drilling.

Mode-Locked: Ultrashort pulses (picosecond or femtosecond) for precision micro-machining and delicate material processing.

Master Oscillator Power Amplifier (MOPA)

Combines a low-power seed laser (the oscillator) with one or more amplifier stages. Offers precise control over pulse duration and repetition rate.

Key Advantages

Exceptional Beam Quality

Achieves near-diffraction-limited output, allowing for ultra-fine focus spots and razor-sharp cuts.High Efficiency

Wall-plug efficiencies often exceed 30%, translating to lower electrical consumption and operating costs.Compact Footprint

All-fiber construction eliminates bulky mirrors and gas tubes, saving valuable floor space.Low Maintenance

Sealed fiber modules require minimal realignment; there are no gas replenishments or large cooling towers.Environmental Robustness

Fiber lasers tolerate vibration, dust, and temperature fluctuations better than free-space systems.

Typical Applications

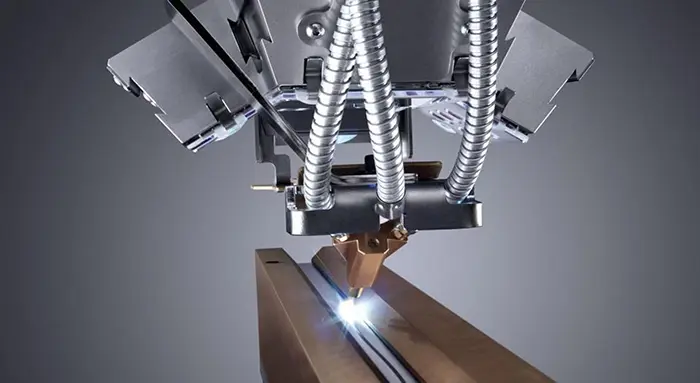

Metal Cutting & Welding

From thin gauge stainless steel to thick aluminum, fiber lasers deliver faster cutting speeds, narrow kerfs, and minimal heat-affected zones.Precision Marking & Engraving

Ideal for serial numbers, barcodes, and logos on metals, plastics, ceramics, and glass with clear contrast and high durability.Micro-Machining

Creates tiny features in electronics, medical devices, and precision components with micron-level accuracy.Additive Manufacturing

Powers laser-based 3D printing methods—such as selective laser melting—by melting metal powders with uniform energy distribution.Scientific Research

Offers tunable pulse parameters for spectroscopy, nonlinear optics, and other laboratory experiments.

Selecting the Right Fiber Laser

Output Power

Determine based on material thickness and processing speed. Light-duty marking may need 20–50 W; heavy cutting can require 1–10 kW or more.Pulse Characteristics

Choose CW for continuous operations; Q-switched or MOPA for precision tasks requiring high peak power or ultrashort pulses.Beam Delivery

Fixed-focus heads for general cutting; galvo scanners for high-speed marking; long-reach optics for remote welding.Cooling Method

Air-cooled units suffice up to a few hundred watts; higher powers benefit from water-cooling to maintain stable output.Integration & Controls

Look for compatibility with your automation setup, including digital interfaces, software libraries, and safety interlocks.

Maintenance Best Practices

Fiber End-Face Care

Inspect and clean protective windows or lenses routinely to prevent beam distortion.Cooling System Checks

Verify adequate airflow or water flow; monitor temperature sensors and replace filters as needed.Software Updates

Apply firmware patches to optimize performance and maintain safety standards.Periodic Calibration

Engage certified technicians yearly (or per your usage intensity) to verify power output, beam alignment, and system reliability.

Fiber lasers blend advanced photonics with practical engineering, making them a cornerstone of modern manufacturing, research, and precision processing. Understanding their core design, operating principles, and application scopes empowers you to harness their full potential across countless industries.

A fiber laser is a type of solid-state laser in which the active gain medium is an optical fiber doped with rare-earth elements, most commonly ytterbium. Unlike traditional gas or CO₂ lasers, fiber lasers generate, amplify, and guide light entirely within a glass fiber, resulting in a compact, robust, and highly efficient system.

1. Core Components and Design

Doped Fiber Core

The heart of a fiber laser is the fiber itself—an ultra-thin strand of glass whose core is infused with rare-earth ions. When pumped with light, these ions provide the energy needed for laser action.Pump Diodes

High-power semiconductor diodes inject pump light into the fiber’s cladding. The cladding traps the pump light around the core, ensuring uniform excitation of the doped ions.Fiber Bragg Gratings (FBGs)

Inscribed directly into the fiber, these reflective gratings form the laser cavity. One grating reflects most of the light back into the fiber, while the other allows a controlled portion to exit as the output beam.Heat Management

Since the fiber’s small cross-section dissipates heat efficiently along its length, fiber lasers typically require only air-cooling or modest water circulation, even at high power levels.

2. Operating Principle

Optical Pumping

Pump diodes inject light, usually at wavelengths between 915 nm and 976 nm, into the fiber’s cladding.Energy Absorption

Rare-earth ions in the core absorb pump photons, moving electrons to excited states.Stimulated Emission

As electrons relax, they emit coherent photons at the laser’s characteristic wavelength (commonly 1,064 nm).Amplification & Feedback

Photons travel along the fiber, triggering further emissions and amplifying the beam. FBGs at each end of the fiber form a resonant cavity, sustaining laser oscillation.Output Coupling

A partially reflective grating allows a fraction of the amplified light to exit as the high-quality output beam used for processing.

3. Types of Fiber Lasers

Continuous-Wave (CW) Fiber Lasers

Emit a steady, uninterrupted beam. Ideal for cutting, welding, and marking applications where constant power is required.Pulsed Fiber Lasers

Deliver light in controlled bursts. Subcategories include:Q-Switched: High-peak pulses (nanosecond range) for deep engraving and micro-drilling.

Mode-Locked: Ultrashort pulses (picosecond or femtosecond) for precision micro-machining and delicate material processing.

Master Oscillator Power Amplifier (MOPA)

Combines a low-power seed laser (the oscillator) with one or more amplifier stages. Offers precise control over pulse duration and repetition rate.

4. Key Advantages

Exceptional Beam Quality

Achieves near-diffraction-limited output, allowing for ultra-fine focus spots and razor-sharp cuts.High Efficiency

Wall-plug efficiencies often exceed 30%, translating to lower electrical consumption and operating costs.Compact Footprint

All-fiber construction eliminates bulky mirrors and gas tubes, saving valuable floor space.Low Maintenance

Sealed fiber modules require minimal realignment; there are no gas replenishments or large cooling towers.Environmental Robustness

Fiber lasers tolerate vibration, dust, and temperature fluctuations better than free-space systems.

5. Typical Applications

Metal Cutting & Welding

From thin gauge stainless steel to thick aluminum, fiber lasers deliver faster cutting speeds, narrow kerfs, and minimal heat-affected zones.Precision Marking & Engraving

Ideal for serial numbers, barcodes, and logos on metals, plastics, ceramics, and glass with clear contrast and high durability.Micro-Machining

Creates tiny features in electronics, medical devices, and precision components with micron-level accuracy.Additive Manufacturing

Powers laser-based 3D printing methods—such as selective laser melting—by melting metal powders with uniform energy distribution.Scientific Research

Offers tunable pulse parameters for spectroscopy, nonlinear optics, and other laboratory experiments.

6. Selecting the Right Fiber Laser

Output Power

Determine based on material thickness and processing speed. Light-duty marking may need 20–50 W; heavy cutting can require 1–10 kW or more.Pulse Characteristics

Choose CW for continuous operations; Q-switched or MOPA for precision tasks requiring high peak power or ultrashort pulses.Beam Delivery

Fixed-focus heads for general cutting; galvo scanners for high-speed marking; long-reach optics for remote welding.Cooling Method

Air-cooled units suffice up to a few hundred watts; higher powers benefit from water-cooling to maintain stable output.Integration & Controls

Look for compatibility with your automation setup, including digital interfaces, software libraries, and safety interlocks.

7. Maintenance Best Practices

Fiber End-Face Care

Inspect and clean protective windows or lenses routinely to prevent beam distortion.Cooling System Checks

Verify adequate airflow or water flow; monitor temperature sensors and replace filters as needed.Software Updates

Apply firmware patches to optimize performance and maintain safety standards.Periodic Calibration

Engage certified technicians yearly (or per your usage intensity) to verify power output, beam alignment, and system reliability.

Fiber lasers blend advanced photonics with practical engineering, making them a cornerstone of modern manufacturing, research, and precision processing. Understanding their core design, operating principles, and application scopes empowers you to harness their full potential across countless industries.