1. Vipimo

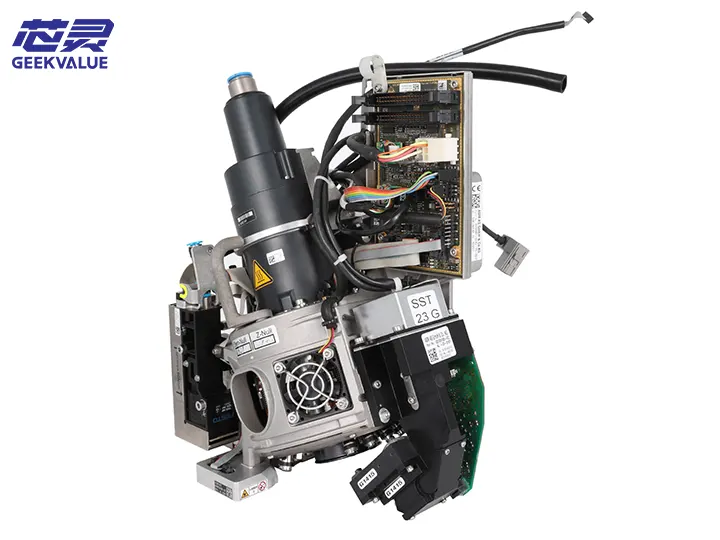

Mfano: 03105195 (Nambari 23 ya kamera ya sehemu)

Vifaa vinavyotumika: Mashine ya kuweka ASM (kama vile mfululizo wa SIPLACE)

Aina ya kamera: kamera ya ubora wa juu ya CCD/CMOS ya viwanda (mada mahususi)

Azimio: kwa kawaida 1MP~5MP (huruhusu utambuzi wa sehemu ya usahihi, kama vile vipengee vya ukubwa mdogo kama vile 0201, 01005)

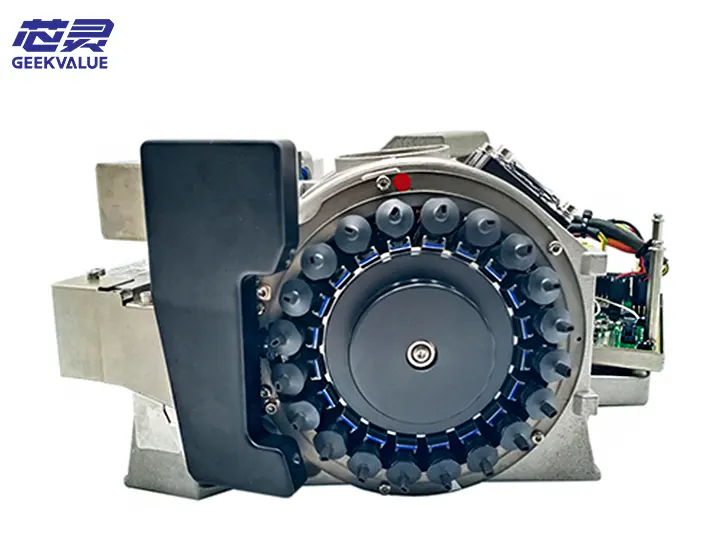

Chanzo cha mwanga: Chanzo cha taa ya pete ya LED iliyojumuishwa (mwangaza unaoweza kubadilishwa/hiari ya urefu wa mawimbi kadhaa)

Kasi ya fremu: 30~60fps (upigaji risasi wa kasi ya juu ili kuhakikisha ufanisi wa uwekaji)

Kiolesura cha mawasiliano: GigE au Kiungo cha Kamera (usambazaji wa data ya kasi ya juu na mwenyeji)

Kiwango cha ulinzi: IP50 (muundo usio na vumbi, unaofaa kwa mazingira ya warsha)

2. Kazi na madhara

Kazi kuu:

Kitambulisho cha kipengele: tambua nafasi ya sehemu, pembe, polarity, ukubwa, nk kupitia usindikaji wa picha.

Marekebisho ya usawa: shirikiana na kichwa cha uwekaji ili kufikia uwekaji wa usahihi wa juu (usahihi unaweza kufikia ± 25μm).

Ugunduzi wa kasoro: tambua bidhaa zenye kasoro kama vile vipengee vilivyovunjika, pini zilizoharibika, polarity ya nyuma, n.k.

Mazingira ya maombi:

Uwekaji wa awali wa mwonekano wa vipengele vya usahihi (kama vile BGA, QFP, vipingamizi na vidhibiti) katika njia za uzalishaji za SMT.

Inatumika kwa kushirikiana na nozzle No. 23 ili kuhakikisha kuwa hakuna kupotoka katika mchakato wa kupachika.

3. Vipengele vya msingi

Usahihi wa hali ya juu: Algoriti ya pikseli ndogo huboresha usahihi wa nafasi.

Mwangaza unaobadilika: Rekebisha kwa akili nguvu ya chanzo cha mwanga ili kuendana na vipengele vilivyo na sifa tofauti za kuakisi.

Uzingatiaji wa haraka: Utendaji wa otomatiki hukabiliana na mabadiliko katika unene wa sehemu.

Utangamano: Inasaidia aina mbalimbali za vifungashio vya vipengele (kutoka CHIP hadi sehemu zenye umbo maalum).

Muundo wa kuzuia mwingiliano: Kuzuia mtetemo, kuingiliwa kwa sumakuumeme, na kukabiliana na mazingira ya kiwanda.

4. Makosa ya kawaida na ufumbuzi

Jambo la kosa Sababu inayowezekana Suluhisho

Kamera haiwezi kutambua kijenzi. Chanzo cha mwanga kimeharibika/kuchafuliwa. Safisha lenzi au chanzo cha mwanga na uangalie ikiwa LED inawashwa kawaida.

Picha iliyofifia/ iliyopotoka. Urefu wa umakini wa lenzi umefungwa au kuchafuliwa. Rekebisha mwelekeo na usafishe vipengele vya macho kwa kitambaa kisicho na vumbi.

Kukatizwa kwa mawasiliano (hitilafu ya utumaji picha) Kiolesura kisicho na kebo/kioksidishaji Chomeka tena kebo na ubadilishe GigE iliyoharibika au kebo ya umeme.

Usahihi wa utambuzi hupungua Urekebishaji wa kigezo cha kurekebisha au tatizo la toleo la programu Sawazisha upya kamera na usasishe programu dhibiti inayoonekana.

Kuzidisha joto kwa kamera Utoaji hafifu wa joto au upakiaji mwingi unaoendelea Angalia kipeperushi cha kupoeza na uwashe upya kifaa baada ya kukisimamisha kwa kupoeza.

5. Mapendekezo ya matengenezo na huduma

Matengenezo ya kila siku:

Safisha lenzi na chanzo cha mwanga mara kwa mara (mara moja kwa wiki, tumia kitambaa kisicho na vumbi na pombe).

Angalia ikiwa muunganisho wa kebo ni thabiti.

Urekebishaji wa mara kwa mara:

Fanya urekebishaji wa macho ya kamera kila mwezi (tumia ubao wa urekebishaji wa kawaida).

Thibitisha ulinganifu wa chanzo cha mwanga ili kuepuka uamuzi usiofaa unaosababishwa na mwangaza usio sawa.

Sasisho la programu:

Sasisha kiendeshi cha kamera kwa wakati na kanuni ya maono ya mashine ya uwekaji.

6. Uboreshaji wa teknolojia na uingizwaji

Chaguo za kuboresha: Muundo mpya unaweza kutumia ubora wa juu au vipengele vya kugundua kasoro za AI.

Utangamano wa uingizwaji: Utangamano na vidhibiti vya mashine ya uwekaji (kama vile ASM SIPLACE OS) unahitaji kuthibitishwa.

Usaidizi wa huduma: Vipuri na huduma za ukarabati zinaweza kupatikana kupitia simu ya dharura ya huduma ya ASM au mawakala walioidhinishwa.

Kupitia utangulizi ulio hapo juu, unaweza kuelewa kikamilifu vipengele vya utendakazi na matengenezo ya kamera ili kuhakikisha utendakazi wake thabiti katika njia ya uzalishaji ya SMT. Ikiwa kosa haliwezi kuondolewa, inashauriwa kuwasiliana na wafundi wetu wa kitaaluma kwa usindikaji.