Laser engraving machines have become essential tools across a wide range of industries—from personalized gifts and industrial marking to woodworking and metal fabrication. If you’re considering buying one, the first question that comes to mind is: How much does a laser engraving machine cost?

The answer is more complex than a single number. Prices vary significantly based on machine type, power, brand, features, and application. This comprehensive guide breaks down everything you need to know about laser engraving machine costs, helping you make an informed purchasing decision.

Table of Contents

What Influences the Cost of a Laser Engraving Machine?

Before diving into numbers, let’s explore the major factors that determine the price:

1. Laser Type

Different lasers (CO2, fiber, diode) cater to different materials and engraving depths. The laser source plays a significant role in determining the price.

2. Power Output

Measured in watts, higher power enables deeper and faster engraving. More power typically equals a higher cost.

3. Bed Size

The larger the working area, the more expensive the machine. Large-format machines allow you to engrave bigger items or run multiple jobs at once.

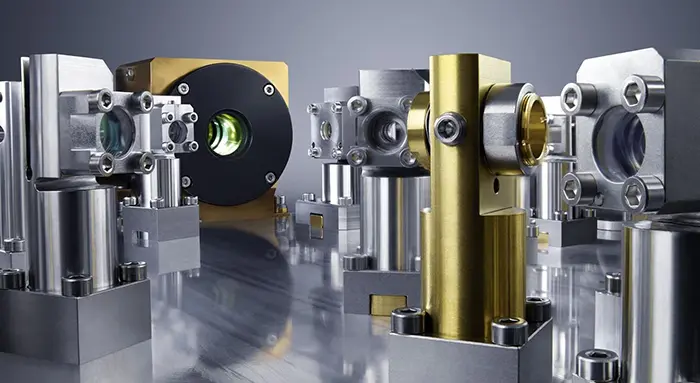

4. Software and Controls

Machines with intuitive software, advanced controls, and compatibility with design programs often carry a premium.

5. Build Quality and Brand Reputation

Established brands charge more but often provide better reliability, customer support, and longer warranties.

6. Features

Features such as autofocus, rotary attachments, water cooling, and safety enclosures can significantly affect cost.

Types of Laser Engraving Machines and Their Price Ranges

Laser engraving machines come in different configurations, each suitable for specific tasks and industries.

1. Diode Laser Engraving Machines

Cost Range: $100 – $1,000

Best For: Hobbyists, DIY, small wood or paper crafts

Example: Ortur, NEJE

2. CO2 Laser Engraving Machines

Cost Range: $500 – $20,000

Best For: Wood, leather, acrylic, glass, rubber

Example: OMTech, Glowforge, Epilog

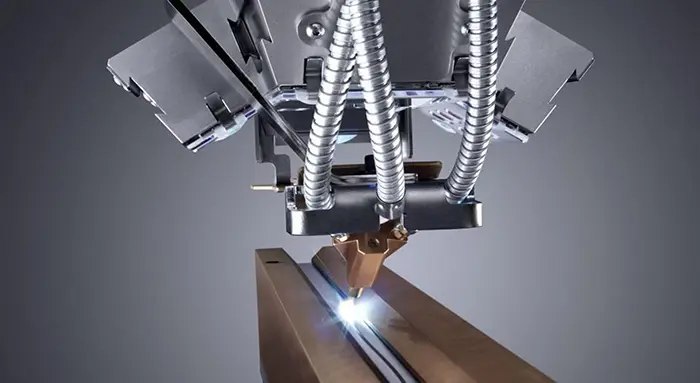

3. Fiber Laser Engraving Machines

Cost Range: $2,000 – $80,000+

Best For: Metals, industrial parts, jewelry, marking tools

Example: MOPA, JPT, Raycus, IPG lasers

Entry-Level Laser Engravers

Perfect for beginners, artists, or home-based businesses.

Key Features:

Lower wattage (5W–40W)

Small working area (100x100mm – 300x300mm)

Basic safety features

Limited material compatibility

Estimated Costs:

Diode Lasers: $100 – $800

Small CO2 Lasers: $400 – $2,000

Pros:

Affordable

Compact size

Good for basic engraving

Cons:

Slower processing speed

Limited to soft materials

Not ideal for heavy-duty work

Mid-Range Laser Engravers

Suitable for small to medium-sized businesses.

Key Features:

Medium wattage (40W–100W)

Working area (400x600mm – 900x600mm)

Autofocus, rotary attachments

More robust structure

Estimated Costs:

CO2 Lasers: $2,000 – $10,000

Low-Power Fiber Lasers: $4,000 – $15,000

Pros:

Versatile

Capable of handling a variety of materials

Greater precision

Cons:

Higher learning curve

Requires dedicated space and ventilation

Industrial-Grade Laser Engravers

Built for high-volume production and heavy-duty applications.

Key Features:

High wattage (100W–500W+)

Large bed size (1000x1000mm or more)

Cooling systems, dust extraction

Advanced software integration

Estimated Costs:

Fiber Lasers: $20,000 – $80,000+

High-End CO2 Systems: $10,000 – $30,000

Pros:

Durable and fast

High precision for mass production

Long lifespan

Cons:

High upfront investment

Requires professional maintenance

Fiber vs CO2 vs Diode Laser Cost Comparison

| Feature | Diode Laser | CO2 Laser | Fiber Laser |

|---|---|---|---|

| Price Range | $100–$1,000 | $500–$20,000 | $2,000–$80,000 |

| Best For | Hobby use | Wood, acrylic | Metals |

| Lifespan | 5,000–10,000 hrs | 8,000–12,000 hrs | 100,000+ hrs |

| Speed | Slow | Medium | Fast |

| Maintenance | Low | Medium | Low |

Additional Costs to Consider

1. Shipping and Import Fees

Large machines may incur hundreds or thousands in delivery fees.

2. Software and Licensing

Some high-end machines require paid software licenses.

3. Maintenance and Spare Parts

Lenses, mirrors, laser tubes, and belts may need replacement.

4. Power Consumption

High-wattage machines draw more electricity.

5. Safety Equipment

Including eyewear, enclosures, and ventilation systems.

6. Training and Setup

First-time users may need professional training.

Used vs New Machines

Used Machines

Cost: 30%–70% lower than new

Pros: Lower price, faster ROI

Cons: Shorter lifespan, possible wear and tear, limited warranty

New Machines

Pros: Latest technology, warranty, better support

Cons: Higher upfront cost

When buying used, ensure the machine is inspected, test-run, and that original software is included.

Should You Lease, Rent, or Buy?

Leasing

Good for growing businesses

Lower upfront cost

Monthly payments

Renting

Short-term projects

Try-before-you-buy

Buying

Long-term investment

Better ROI over time

Full ownership and control

Tips for Saving Money

Buy from reputable suppliers with transparent pricing

Compare multiple models and quotes

Consider refurbished or gently used machines

Look for bundle deals (machine + accessories)

Invest in training to avoid costly errors

Don’t overspend on power you don’t need

Conclusion

The cost of a laser engraving machine can range from under $100 to well over $80,000 depending on your needs and application. Diode lasers are great for hobbyists, CO2 lasers offer versatility for small businesses, and fiber lasers excel in industrial environments.

Before purchasing, consider the type of material you'll be working with, production volume, available space, and long-term business goals. Remember to factor in additional expenses like software, maintenance, and training.

If you're unsure where to start, reach out to industry professionals or suppliers who offer consultation services. A well-informed purchase can save you money and set you up for long-term success.

Need help choosing the right laser engraving machine or want expert repair and maintenance service? Our team of technicians specializes in helping businesses get the best performance out of their equipment. Contact us today!