Mashiinka meelaynta ASM MAPPING Tool waa qalab software ah oo si gaar ah loogu sameeyay ASM (Assembléon/Siemens) qalabka dusha sare ee taxanaha ah, inta badan loo isticmaalo meelaynta saxda ah iyo jaangooynta boosaska meelaynta qaybaha. Qalabkani wuxuu isticmaalaa tignoolajiyada sawir-qaadista sare ee saxda ah si loo gaaro khariidaynta saxda ah ee looxyada PCB, qaybaha iyo boosaska meelaynta, hubinta in mashiinka meelaynta uu si sax ah u dhigi karo qaybaha booska loogu talagalay.

2. Hawlaha muhiimka ah

Aqoonsiga barta tixraaca iyo hagaajinta

Si toos ah u aqoonso Fiducial on PCB Mark (goob tixraac)

Magdhaw ka leexinta booska inta lagu jiro wax soo saarka PCB iyo isku dhejinta

Waxay taageertaa aqoonsiga qaabab iyo qalabyo badan oo tixraac ah

Khariidaynta booska qaybaha

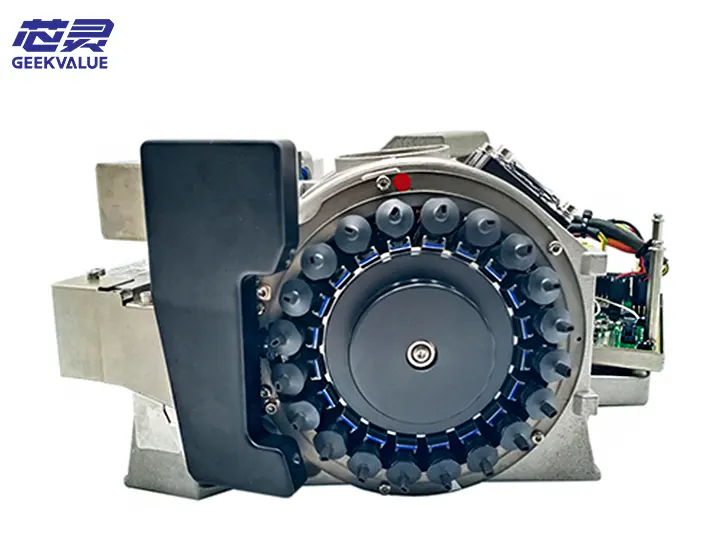

Aqoonsiga saxda ah ee saxda ah ee booska qaybta ee quudiyaha

Magdhaw ka leexashada booska rakibaadda quudiyaha

Aqoonso jihada kala-goynta qaybaha

hagaajinta booska fuulista

Si firfircoon u hagaaji isku-duwayaasha dhejinta iyadoo loo eegayo booska PCB ee dhabta ah

Magdhaw khaladka booska uu sababay PCB-ga beddelka kulaylka

Shaqaale sax ah oo madax banaan oo ka kooban guddiyo badan

3D dhererka khariidad

Cabbirka dhererka qaybaha iyo magdhowga

Ogaanshaha iyo magdhowga bogga dagaal ee PCB

Cabbirka dhumucda koollada alxanka (Qaar ka mid ah moodooyinka horumarsan)

III. Tilmaamaha farsamada

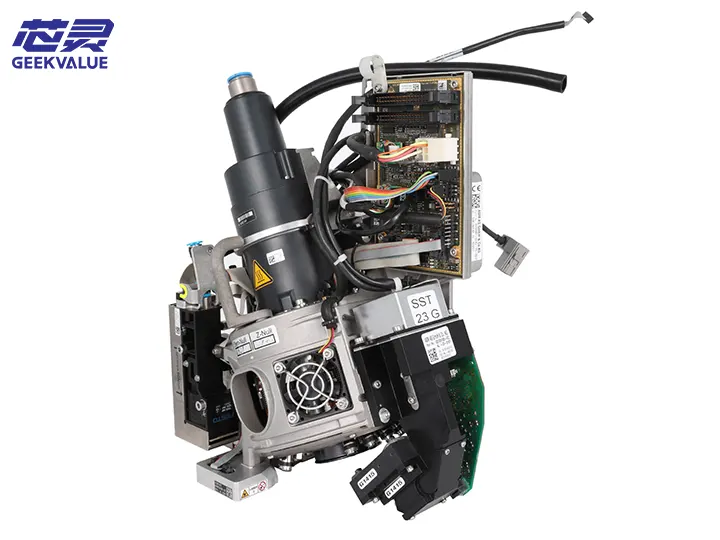

Nidaamka muuqaalka sare ee saxda ah

Isticmaalka kamarad CCD oo heer sare ah (sida caadiga ah 5-20μm xallinta)

Nidaamka nalka ilaha-iftiinka badan (iftiinka coaxial, iftiinka dhinaca, iftiinka giraanta, iwm.)

Algorithm farsamaynta sawirka horumarsan

Algorithm magdhowga caqliga

Magdhawga caalamiga ah ee ku salaysan habka afar geesoodka ugu yar

Tignoolajiyada magdhawga deegaanka

Heerkulka magdhowga qulqulka

Karti farsamayn oo hufan

Taageer kaamiro badan oo isbarbar socda

Tignoolajiyada is-habaynta degdega ah (<1 ilbiriqsi/dhibcood)

Awooda habaynta xogta weyn (waxay taageertaa tiro badan oo PCB-yada la soo saaray)

IV. Socodka shaqada

Diyaargarow horudhac ah

Soo deji Gerber/Faylasha naqshadaynta PCB

Deji halbeegyada tixraaca

Qeex goobta khariidaynta iyo saxnaanta shuruudaha

Habka khariidaynta tooska ah

PCB-ga caalamiga ah ee tixraaca

Tilmaanta tixraaca maxalli meeleyn sax ah

Helitaanka booska qaybaha

Falanqaynta xogta iyo xisaabinta magdhowga

Xaqiijinta natiijada

Jilitaanka meelaynta dhabta ah

Xaqiijinta gabalka koowaad

Soosaarka xogta magdhowga mashiinka meelaynta

V. Faa'iidooyinka codsiga

Hagaajinta saxnaanta meelaynta

Waxay hagaajin kartaa saxnaanta meelaynta 30-50%

Iska yaree dhibaatooyinka tayada leh ee ay keento leexashada booska

Hagaajinta waxtarka wax soo saarka

Yaree wakhtiga sixitaanka gacanta

Iska yaree qaybta ugu horraysa heerka fashilka

Taageer beddelka khadka degdegga ah

Kobcinta awooda habka

Taageer qaybaha garoonka aadka u-fiican (01005, 0.3mm BGA, iwm.)

La qabso naqshadaynta PCB-ga cufnaanta sare leh

Qabo loox dabacsan iyo loox qaabaysan

Iska yaree kharashka wax soo saarka

Iska yaree qashinka alaabta

Yaree heerka dib-u-shaqaynta

Kordhi nolosha qalabka

VI. Xaaladaha codsiga caadiga ah

Alaabta elektarooniga ah ee saxda ah

Telefoonka gacanta, Motherboard-ka tablet-ka

Qalabka la xidhi karo

Isku-xidhka cufnaanta sare (HDI).

Dufcad yar oo wax soo saar badan oo kala duwan

Aerospace electronics

Qalabka caafimaadka

Elektrooniga baabuurta

Shuruudaha habka gaarka ah

Habka buuxinta hoose

Xirmooyinka 3D ee xirmada

Meelaynta qayb-qaabeeya

VII. Moodooyinka guud ee suuqa

ASM SIPLACE aaladaha taageeraya taxanaha

Khariidaynta SIPLACE Pro

waan ka helay

SIPLACE 3D mapping

Qalabka horumarinta ee xisbiga saddexaad

CAMALOT Mapping Suite

Nidaamka Khariidaynta Khabiirka SMT

Taxanaha Viscom iMap

VIII. Isbeddellada Horumarineed ee Mustaqbalka

Is dhexgalka Teknolojiyadda AI

Magdhaw La Qabsiga Ku Salaysan Barashada Qoto dheer

Saadaasha cillad maskaxeed

Dejinta Halbeegga Is-Wanaajinta

Warshadaha 4.0 Isdhexgalka

Is-dhexgalka Qoto dheer ee Nidaamka MES

Falanqaynta Xogta Cloud iyo Hagaajinta

Codsiga Farsamada Mataanaha Dijital ah

Isku-dhafka Hawlaha-Multi-Function

Lagu daray SPI iyo AOI Functions

Magdhawga-waqtiga dhabta ah ee khadka tooska ah

Hawsha Dayactirka Saadaasha

Sida nidaamka kaaliyaha muhiimka ah ee wax soo saarka casriga ah ee SMT, ASM meelaynta mashiinka MAPPING wuxuu ka soo baxayaa meelaynta fudud iyo qalabaynta si loo helo xal dhamaystiran oo isku dhafan tayada kormeerka, hagaajinta habka iyo maareynta wax soo saarka, siinta taageero farsamo oo muhiim ah oo loogu talagalay horumarinta warshadaha wax soo saarka elektaroonigga ah ee dhinaca sirdoonka iyo dabacsanaanta.