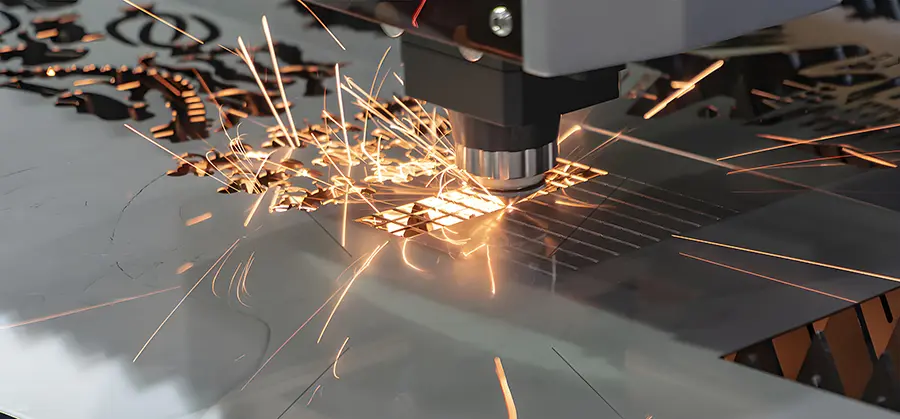

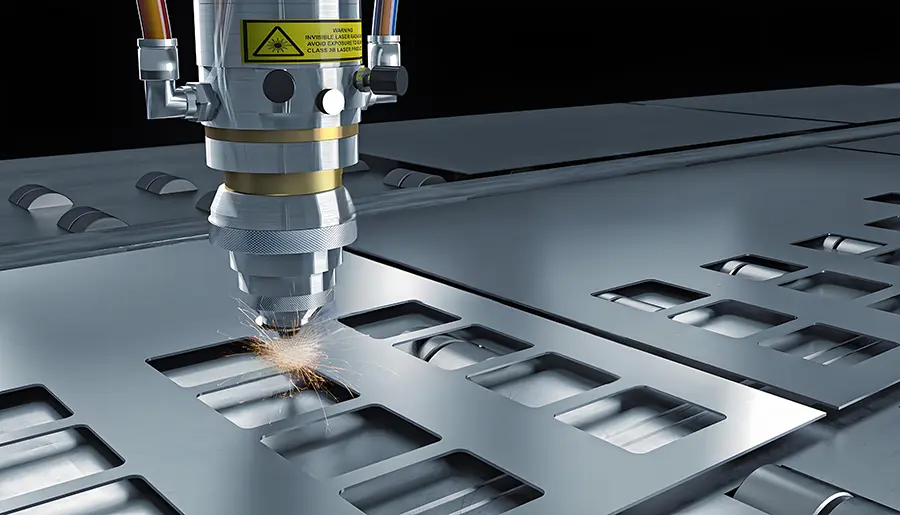

Fiber Laser vs. CO2 Laser: Which Is Better for Your Application?

When choosing between a fiber laser and a CO2 laser, the decision often comes down to your specific needs, materials, and budget. Both technologies dominate industries like manufacturing, automotive, and aerospace, but they differ significantly in efficiency, versatility, and long-term costs. In this guide, we’ll break down the pros, cons, and best-use cases for each—helping you make an informed, Google-friendly decision that aligns with modern search trends.

How Do Fiber Lasers and CO2 Lasers Work?

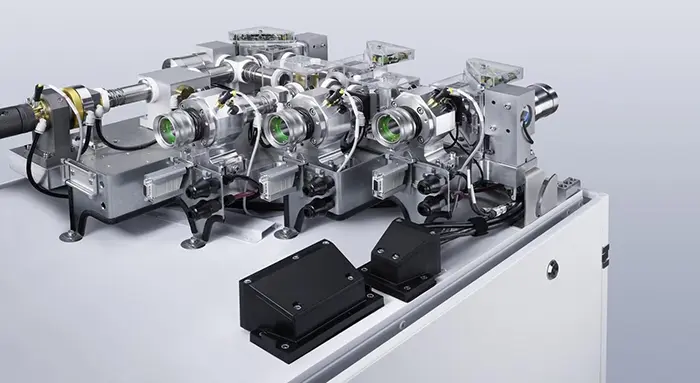

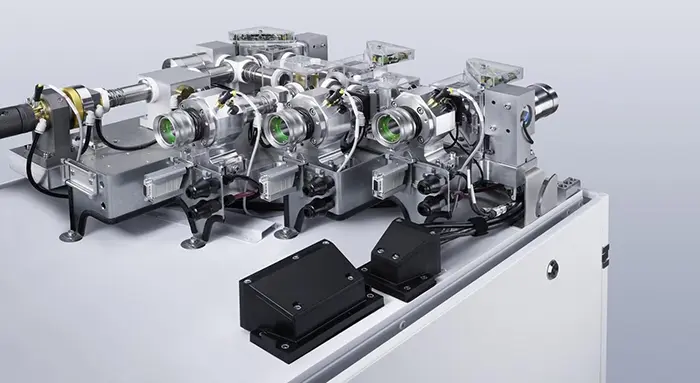

Fiber Lasers

Fiber laser belong to the solid-state laser category. Their core component is an optical fiber doped with rare-earth elements such as erbium, ytterbium, or thulium. When stimulated by diode pumps, these elements emit photons that travel through the fiber, amplifying into a coherent, high-intensity beam. The resulting wavelength typically falls in the 1,064 nm range (near-infrared), which metals like steel, aluminum, and copper absorb efficiently.

Key advantages of this design include:

Compact Size: Fiber resonators are smaller than CO2 systems.

Stability: Minimal alignment issues due to the fiber’s flexibility.

Beam Quality: Exceptionally focused beams enable micro-precision for tasks like medical device manufacturing or aerospace part marking.

CO2 Lasers

CO2 lasers operate using a gas mixture—primarily carbon dioxide, with nitrogen and helium—contained in a sealed tube. When electrified, the gas molecules vibrate and emit photons, creating a laser beam at 10,600 nm (mid-infrared). This longer wavelength interacts better with organic and non-metallic materials, such as wood, acrylic, leather, and plastics, making CO2 systems a staple in industries like signage and textiles.

Notable features include:

Material Flexibility: Excels with mixed or layered materials (e.g., painted metals, laminated plastics).

Smooth Cutting Edges: The longer wavelength melts materials more evenly, reducing post-processing for delicate projects.

Key Differences Between Fiber Lasers and CO2 Lasers

Understanding the fundamental distinctions between fiber and CO2 lasers is critical for selecting the right tool for your projects. While both technologies excel in material processing, their core differences in wavelength, energy efficiency, and interaction with materials dictate their suitability for specific tasks.

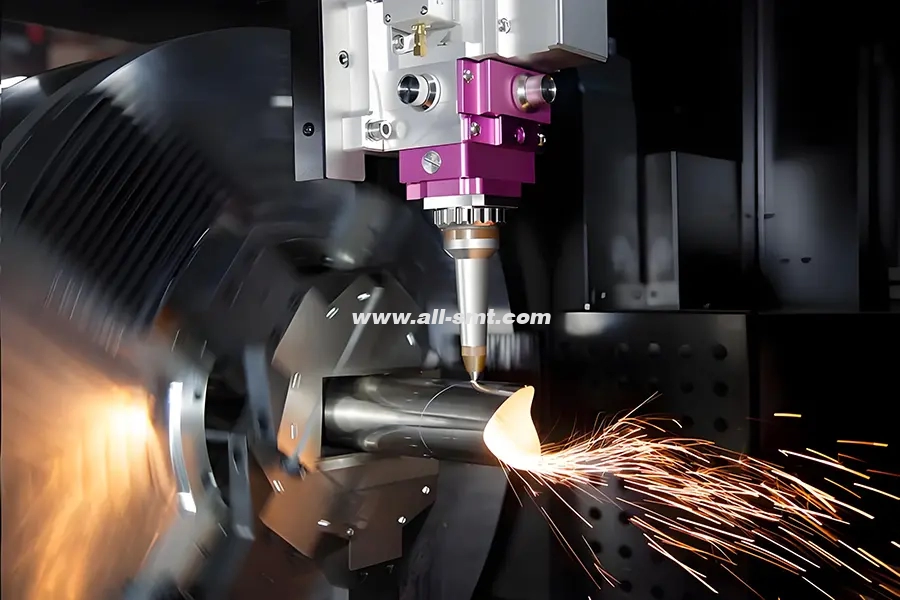

A. Metals vs. Non-Metals: Which Laser Dominates?

Fiber Lasers: Unmatched for metals, especially reflective ones (e.g., copper, brass). The 1,064 nm wavelength is readily absorbed by metallic surfaces, enabling clean cuts with minimal thermal distortion. Applications include:

Automotive: Cutting engine components and chassis parts.

Electronics: Engraving serial numbers on circuit boards.

Jewelry: Etching intricate designs on gold or titanium.

CO2 Lasers: Ideal for non-metallic materials. Their 10,600 nm wavelength vaporizes organics cleanly without burning. Common uses:

Woodworking: Crafting decorative panels or furniture.

Packaging: Cutting acrylic displays or PET plastic containers.

Fashion: Laser-cutting leather for shoes or handbags.

Hybrid Tip: For projects involving coated metals (e.g., powder-coated aluminum), CO2 lasers can process both the metal and its coating in one pass.

B. Speed and Efficiency

Fiber Lasers: Operate 2–5 times faster than CO2 lasers on metals. For example, cutting 1mm stainless steel with a fiber laser takes seconds, while a CO2 laser might require minutes. This efficiency stems from higher absorption rates and concentrated energy.

CO2 Lasers: Faster on non-metals. Cutting 10mm acrylic with a CO2 system is quicker and cleaner than with a fiber laser.

C. Precision and Finish Quality

Fiber Laser: Produce sharper edges on thin metals (0.1–20mm thickness) with heat-affected zones (HAZ) as narrow as 0.1mm. This is critical for medical implants or microelectronics.

CO2 Lasers: Deliver smoother finishes on plastics and wood, reducing the need for sanding or polishing.

fiber laser or CO2 laser Processing performance comparison

| Comparison Dimensions | Fiber Laser | CO₂ Laser |

|---|---|---|

| Cutting speed | Fast metal cutting speed and high efficiency for thin plates | More balanced performance on non-metals and thick plate metals |

| Slit width | Extremely narrow (≤0.1mm), neat incision | Wider (0.2–0.3 mm), may require secondary grinding |

| Minimum cutting thickness | Can cut ultra-thin metal plates below 0.1mm | The thinnest is about 0.5mm, suitable for general materials |

| Cutting surface quality | No secondary processing required, smooth edges | Edges may be burnt and require post-processing |

| Multi-layer cutting capability | Supports multi-layer optical fiber superposition without obvious attenuation | The attenuation of multi-layer processing is obvious |

Operational Costs and Long-Term Value

Initial Investment

Fiber Lasers: Higher upfront costs(starting around 30,000forbasicmodels,upto30,000forbasicmodels,upto500,000 for high-power industrial systems) .

CO2 Lasers: More affordable entry points (15,000–15,000–100,000), suitable for small workshops or startups.

Energy Consumption

Fiber Lasers: Convert 30–50% of electrical input into laser energy, resulting in lower power bills. For instance, a 2kW fiber laser might consume 6kW of electricity, while a 4kW CO2 laser uses 25kW.

CO2 Lasers: Less energy-efficient due to gas excitation and cooling demands.

Maintenance and Lifespan

Fiber Lasers: Nearly maintenance-free. With no mirrors or lenses to align and a lifespan exceeding 100,000 hours, downtime is minimal.

CO2 Lasers: Require regular upkeep:

Gas replenishment every 1–2 years.

Optics cleaning to prevent residue buildup.

Tube replacements every 10,000–40,000 hours.

Cost Example: A mid-sized fabrication shop using a fiber laser saved $12,000 annually on energy and maintenance compared to its older CO2 system.

Industry-Specific Applications

The choice between fiber and CO2 lasers isn’t just about technical specifications—it’s about solving real-world challenges in specific industries. Different sectors prioritize factors like material compatibility, production speed, or finish quality, shaping their preference for one technology over the other. Below, we examine how these lasers drive innovation across key fields, starting with applications where fiber lasers deliver unparalleled value.

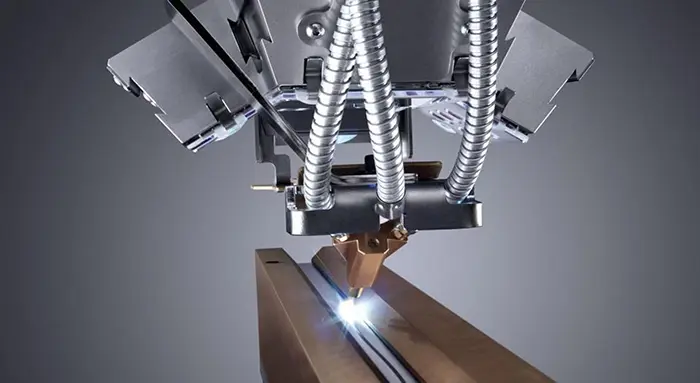

Where Fiber Lasers Shine

Aerospace: Cutting titanium alloys and carbon fiber composites for aircraft parts.

Energy: Engraving solar panels or welding battery components for EVs.

Defense: Marking traceable codes on military-grade hardware.

Where CO2 Lasers Excel

While fiber lasers dominate metal processing, CO2 lasers retain irreplaceable value in industries where versatility and material diversity are paramount. Their longer wavelength and gentler energy delivery make them ideal for organic or heat-sensitive substrates, enabling applications that demand both precision and aesthetic finesse. Below, we explore sectors where CO2 lasers remain the gold standard.

Healthcare: Cutting silicone molds for prosthetics or surgical tools.

Art and Design: Etching detailed patterns on glass or marble.

Agriculture: Labeling plastic packaging for seed or fertilizer bags.

Future Trends and Innovations

As industries evolve, so do laser technologies. Both fiber and CO2 systems are undergoing rapid advancements to address emerging challenges—from sustainability demands to miniaturized manufacturing. Here’s a glimpse into the innovations reshaping their roles:

Fiber Lasers: Advances in pulsed fiber lasers now enable precise welding of dissimilar metals (e.g., copper to aluminum), opening doors for electric vehicle manufacturing.

CO2 Lasers: New RF-excited models offer quieter operation and 30% longer tube life, appealing to schools and small businesses.

Maintenance and life comparison

Fiber Laser: The core components are optical fiber and diode, with a lifespan of more than 100,000 hours; there is no need to replace the laser tube, and only regular dust removal and software upgrades are required.

CO2 Laser: The laser tube generally has a lifespan of 5,000–10,000 hours and needs to be replaced regularly, and the resonant cavity, air cooling or water cooling system needs to be maintained.

Making the Decision: Key Questions to Ask

Primary Materials: Are you working mostly with metals, plastics, or organics?

Production Volume: Will high-speed metal processing justify a fiber laser’s upfront cost?

Workspace Constraints: Do you have the infrastructure to cool a CO2 laser’s larger system?

FAQ

Can a fiber laser cut wood or acrylic?

Yes, but slower and with less precision than a CO2 laser. The beam’s shorter wavelength struggles to vaporize non-metals efficiently.Are CO2 lasers safe for food-grade packaging?

Absolutely. CO2 lasers are FDA-approved for cutting and marking food-safe plastics.Which system is easier to learn?

CO2 lasers have simpler software interfaces, making them beginner-friendly.