In the rapidly advancing world of laser technology, the Geekvalue brand has carved out a prominent position by offering high-quality fiber laser systems that meet the diverse needs of modern manufacturing and industrial applications. Recognized globally for precision, durability, and cutting-edge innovation, Geekvalue’s fiber lasers stand as a symbol of excellence in the fiber laser industry.

This article explores the core aspects of the Geekvalue brand high-quality fiber laser, detailing the features, technology, and advantages that make it a preferred choice for businesses aiming for efficiency and superior results.

Understanding High-Quality Fiber Laser Technology

Fiber lasers have become indispensable in industries such as automotive, electronics, medical, aerospace, and metal fabrication. They use optical fibers doped with rare-earth elements to generate high-intensity laser beams capable of cutting, engraving, and marking with remarkable accuracy and speed.

The term high-quality fiber laser refers to machines that deliver consistent laser power, superior beam quality, reliable operation, and long lifespan. Geekvalue’s fiber lasers are designed with these criteria in mind, integrating advanced components and precision engineering.

Key Features of Geekvalue High-Quality Fiber Laser

1. Superior Laser Sources

At the heart of every Geekvalue fiber laser machine is a high-performance laser source. The brand utilizes top global fiber laser manufacturers such as IPG, Raycus, and Maxphotonics. These laser sources ensure stable output power, excellent beam quality, and energy efficiency, essential for clean cuts and sharp markings.

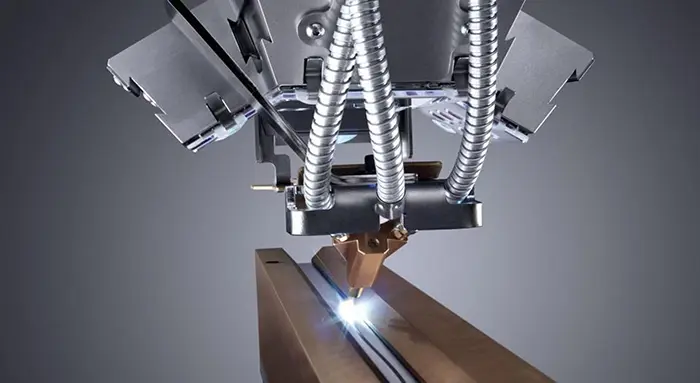

2. Precision Engineering

Geekvalue fiber lasers excel in precision. Whether for micro-scale engraving or thick metal cutting, the machines maintain tight tolerance levels thanks to high-precision motion components, finely tuned optics, and intelligent control software. This ensures repeatability and accuracy across production batches.

3. Durability and Stability

Durability is a hallmark of Geekvalue’s fiber laser machines. Designed with robust metal frames and vibration-resistant structures, these machines deliver stable operation even under continuous industrial workloads. High-quality cooling systems protect the laser source and components, extending machine lifespan and reducing maintenance.

4. Versatility Across Applications

Geekvalue’s high-quality fiber lasers are highly versatile, suitable for cutting metals such as stainless steel, aluminum, brass, and copper. They also perform well in marking and engraving on various metals and some plastics, catering to industries like automotive parts manufacturing, electronics, medical devices, jewelry, and advertising.

5. User-Friendly Software and Controls

Geekvalue integrates advanced but easy-to-use software with its fiber laser systems. Operators benefit from intuitive interfaces that simplify setup, job programming, and machine control. This reduces operator training time and enhances productivity.

Advantages of Choosing Geekvalue High-Quality Fiber Laser

- High Cutting Speed and Efficiency

Thanks to their advanced laser sources and optimized motion systems, Geekvalue fiber lasers offer high cutting speeds without compromising accuracy. This improves throughput and reduces production costs.

- Low Maintenance Costs

The fiber laser technology used by Geekvalue requires less maintenance than traditional CO2 lasers. The solid-state laser sources are durable, and the sealed optical path minimizes contamination risks, resulting in fewer service interruptions.

- Energy Efficiency

Fiber lasers convert electrical power into laser light more efficiently than other laser types. This results in lower energy consumption and operational costs, making Geekvalue’s machines environmentally friendly and economical.

- Compact and Modular Design

Geekvalue fiber laser machines often feature compact footprints and modular designs, enabling easy integration into existing production lines or small workshop spaces.

Industry Applications of Geekvalue High-Quality Fiber Laser

Metal Fabrication: Precision cutting of sheet metal, tubes, and complex parts with smooth edges and minimal heat-affected zones.

Electronics Manufacturing: Fine marking and engraving on circuit boards, components, and casings for traceability and branding.

Jewelry and Luxury Goods: Detailed engraving and cutting on precious metals, maintaining material integrity and aesthetic appeal.

Automotive Industry: Production of parts with high precision and repeatability, including engine components and decorative panels.

Medical Devices: Permanent marking on surgical tools and medical instruments to ensure compliance and traceability.

Advertising and Signage: Creating durable, high-quality signs and logos with intricate designs.

Commitment to Quality and Service

Geekvalue is not just a manufacturer but a comprehensive solution provider. The brand emphasizes quality control at every stage of production, adhering to international standards such as ISO and CE certifications. Customers benefit from thorough testing, ensuring each fiber laser machine delivers peak performance right out of the box.

Furthermore, Geekvalue provides full support services, including installation, operator training, and after-sales maintenance. This commitment helps customers maximize machine uptime and achieve long-term success.