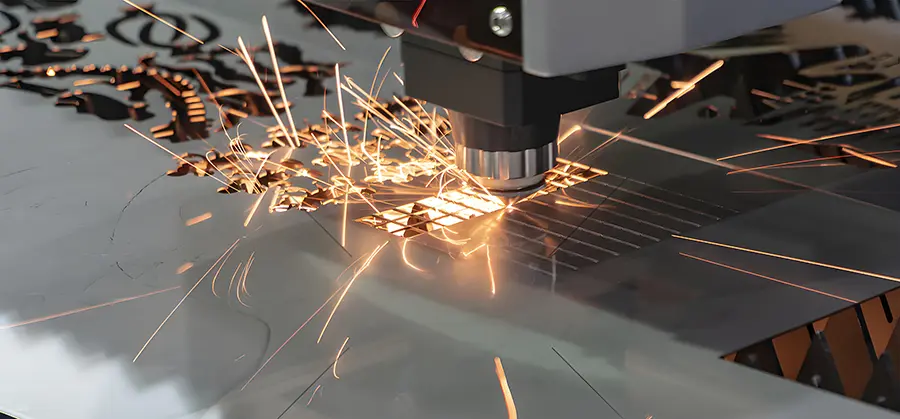

CNC laser machines are a cornerstone of modern manufacturing, known for their precision, speed, and versatility. One of the most common questions buyers and factory owners ask before investing in a machine is: How long does a CNC laser last? Understanding the lifespan of a CNC laser system—and the factors that influence it—can help you maximize its performance and return on investment. In this article, we’ll explore the average lifespan, key maintenance practices, and how to choose a durable CNC laser for your operations.

Understanding the Lifespan of a CNC Laser

CNC Laser Lifespan by Laser Type

The type of laser source used in a CNC machine greatly affects its operational life:

CO2 CNC lasers generally last around 8,000 to 12,000 hours, depending on the tube quality.

Fiber CNC lasers can last over 100,000 hours because they use solid-state components with fewer parts that wear out.

Diode CNC lasers, while less powerful, can last between 10,000 and 50,000 hours.

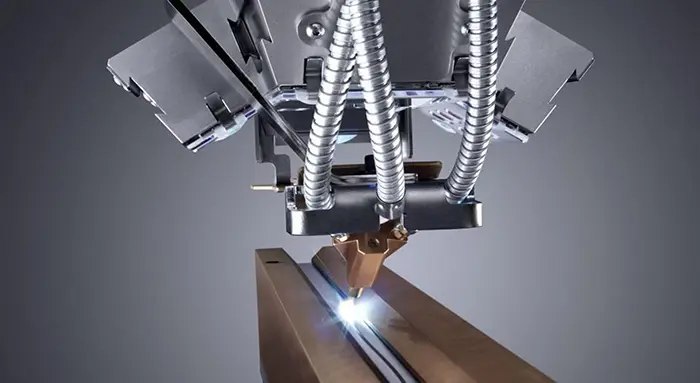

CNC Laser Machine Components That Impact Lifespan

A CNC laser’s longevity is also determined by the durability of its major components:

Laser tube or source

Cooling system

Controller board

Lens and mirrors

Drive motors and linear guides

Regular inspection of these parts is critical to maintaining a long-lasting CNC laser.

Average Lifespan Based on Usage Scenarios

Light use (less than 10 hours/week): 10+ years with minimal maintenance.

Moderate use (20–40 hours/week): 5–7 years, with scheduled maintenance.

Heavy industrial use (24/7 operation): 3–5 years before needing major refurbishing.

How to Extend the Lifespan of a CNC Laser

CNC Laser Preventive Maintenance Tips

Implementing a preventive maintenance program is key to ensuring long-term operation. Here’s what to include:

Weekly mirror/lens cleaning

Checking alignment monthly

Lubricating guide rails and belts

Replacing cooling fluid every 6 months

CNC Laser Cooling System Best Practices

Overheating is one of the top reasons CNC lasers fail early. Keep your cooling system efficient:

Use clean distilled water with anti-corrosion agents

Ensure good airflow around the chiller

Monitor water temperature and flow sensors

CNC Laser Software and Firmware Updates

Outdated software can affect cutting precision and speed. Regularly check:

Controller firmware updates

PC interface compatibility

Optimization settings for different materials

Choosing a Durable CNC Laser Machine

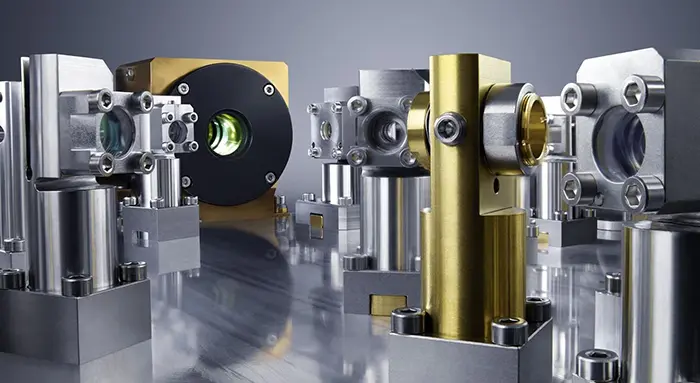

CNC Laser Brand and Build Quality

Not all machines are built equally. When selecting a CNC laser, consider:

Trusted brands with service networks

Strong aluminum or steel frame

Sealed optical paths to reduce contamination

CNC Laser Warranty and Support Services

The length and scope of the warranty can reflect how long the manufacturer expects the CNC laser to last:

Minimum 2-year warranty recommended

Availability of local technical support

Replacement part availability

CNC Laser User Reviews and Lifespan Reports

Check forums, YouTube reviews, and case studies to see how long different CNC lasers are lasting in real-world applications:

Look for machines still running after 5–10 years

Check how many hours they’ve logged

Ask about maintenance costs over time

While the core components of a CNC laser machine have a finite life, proper maintenance and choosing a reputable brand can extend its usability by years. Whether you're using a fiber laser for metal cutting or a CO2 laser for engraving, understanding the factors that affect CNC laser lifespan is essential for making a smart investment.