In the process of improving SMT patch production efficiency, we often focus on the optimization of production capacity planning, production processes and skills training,

but we may have neglected the optimization of the patch machine equipment itself. However, optimization of placement machine equipment is crucial to improving efficiency.

As the age of equipment increases, the failure rate increases accordingly. If equipment failure is not handled in time, it will directly affect production efficiency.

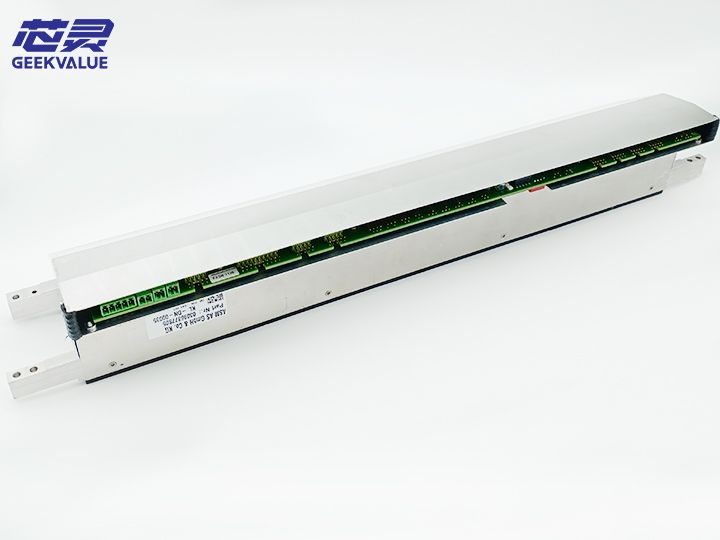

asm placement machine DP motor 03153682

Take an example of a DP motor failure: When the DP motor axis of the placement machine cannot return to the reference, if the DP axis still does not find the zero point

after rotating for more than 3 seconds, it can be determined that the DP axis cannot return to the reference. At this time, an error message will also be displayed on the software.

If the DP axis fails to return to the reference twice in a row, the DP motor will be disabled by the software for the third time. Although the disabled DP motor cannot work,

the entire placement head can still operate normally. However, this leads to an imbalance in the actual placement time, because the more DP motors are disabled,

the longer the waiting time will be. This will directly affect production efficiency.

ASM/Siemens placement machine feeder ASM feeder

Therefore, in order to improve production efficiency, we need to pay attention to the optimization of placement machine equipment. Here are some suggestions:

1. Regular maintenance and upkeep: Perform regular maintenance and upkeep on the equipment to ensure the normal operation of the equipment. Develop a maintenance plan,

including cleaning equipment, lubricating parts, replacing wearing parts, etc. This can reduce the occurrence of equipment failures and improve equipment reliability.

2. Regular inspection and calibration: Regularly check whether all parts of the equipment are working properly and perform necessary calibration. For example,

check whether the movement trajectory of the placement head is accurate and whether it needs adjustment.

3. Update software and firmware: Regularly update the software and firmware of the placement machine equipment to ensure that it has the latest functions and performance.

This helps improve equipment stability and efficiency.

4. Train operators: Ensure that operators are familiar with the operation and maintenance methods of placement machine equipment, and provide

5. Establish an inventory of accessories: Equip an inventory of various accessories to prepare for emergencies. Accessories like DP motors are difficult to repair and have a high failure rate.

It is recommended that SMT factories have 3-8 spare DP motors for each type of patch head on each line, at least one.

In order to help the majority of SMT factories improve efficiency, our company now offers discounts for purchasing DP motors. On the basis of the original price, new ones are 30% off

and second-hand ones are 10% off! ! ! The event time is limited, first come first served, come and grab it now! !

asm placement machine accessories inventory

6. Cooperate with suppliers: Maintain a good cooperative relationship with suppliers of placement machine equipment and obtain timely technical support and maintenance services.

Suppliers can provide professional advice and solutions to help solve equipment problems.

As we all know, for smt patch processing, the most concerned thing is nothing more than quality and efficiency. Through the above measures, we can improve the stability and efficiency

of the placement machine equipment, reduce failure and downtime, and thus improve production efficiency.