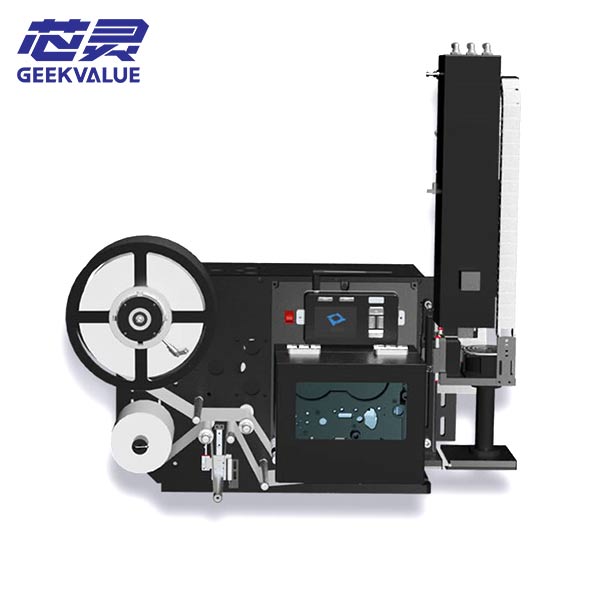

What Is an Online Print Label Feeder?

An online print label feeder is an automated equipment that integrates feeding, printing, and labeling in one system. It is widely used in electronic material production and SMT factories for efficient tray labeling of electronic materials. By combining automatic tray feeding, real-time label printing, precise labeling, and CCD inspection, it greatly improves productivity and labeling accuracy while reducing manual errors.

Core Functions of the Online Print Label Feeder

1. Automatic Feeding

Equipped with a multi-station tray loading rack

Automatically loads and corrects tray positions

Ensures each tray enters the workflow accurately

2. High-Precision Printing & Labeling

Directly connected to the MES system

Automatically calls the right printing template for each product

Labeling error within ±1 mm, ensuring precision

3. Label Content Verification

Built-in CCD inspection system

Re-checks label content for accuracy

Reduces labeling errors and enhances product quality

Technical Advantages

Full automation reduces manual handling

High efficiency improves throughput and consistency

Accurate positioning ensures perfect tray alignment

Seamless MES integration for traceability and intelligent production

Applicable Scenarios & Industry Use

The Online Print Label Feeder PN:YIG ZXDY100L is widely applied in:

SMT production lines – for incoming material tray labeling

Electronic component factories – for finished product identification

Automated manufacturing workshops – requiring precise and high-speed labeling

By automating the entire process, it simplifies operations, reduces manpower requirements, and ensures error-free production labeling.

Why Choose the PN:YIG ZXDY100L Label Feeder?

Designed for modern SMT factories and electronics manufacturers

Delivers higher efficiency and accuracy compared to manual labeling

Improves product traceability with MES integration

Reduces operational costs by minimizing human intervention

In summary, the Online Print Label Feeder PN:YIG ZXDY100L is an indispensable labeling solution for electronic material and SMT industries. Its automation, accuracy, and efficiency make it the ideal choice for companies seeking to upgrade production lines and enhance quality control.

Faq

-

What is the function of an online print label feeder?

An online print label feeder integrates automatic feeding, label printing, precise labeling, and CCD verification. It ensures trays are accurately positioned, labels are applied within ±1 mm precision, and all content is re-checked for accuracy, improving both efficiency and quality in SMT and electronic production lines.

-

How does the PN:YIG ZXDY100L Label Feeder improve production efficiency?

By automating feeding, printing, and labeling, the PN:YIG ZXDY100L eliminates repetitive manual tasks. It also connects directly to the MES system, automatically calling the right template for each product, which speeds up operations and ensures traceable, error-free labeling.

-

What industries benefit most from using an online label feeder?

Online print label feeders are most commonly used in SMT factories, electronics manufacturing plants, and automated workshops. They are ideal for both incoming material tray labeling and finished product labeling, especially where high accuracy and speed are required.

-

Can the Label Feeder integrate with existing MES systems?

Yes. The PN:YIG ZXDY100L supports seamless MES integration. It can automatically pull label data and print templates, ensuring real-time traceability and consistency with production line requirements.

-

Why choose an automated labeling feeder instead of manual labeling?

Manual labeling is time-consuming and prone to human errors. An automated label feeder reduces labor costs, improves accuracy, ensures consistent placement, and maintains high-speed production without interruptions.