1. Product Overview and Technical Specifications

1.1 Basic Parameters

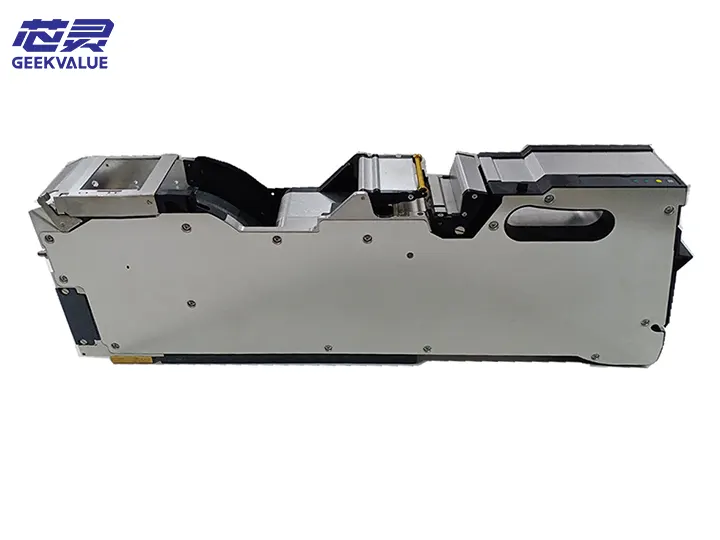

Model: 00141397

Type: Electric Feeder with Sensor

Applicable Strip Width: 72mm (Compatible with 68-72mm)

Feeding Pitch: 4/8/12/16/20/24mm Programmable

Maximum Component Height: 15mm

Strip Thickness Range: 0.3-2.0mm

Dimensions: 320mm×120mm×95mm

Weight: 3.5kg

Service Life: ≥30 million feeding cycles

Protection Level: IP54

1.2 Electrical Parameters

Working Voltage: 24VDC±10%

Power Consumption: 25W in Normal Mode, 50W in Peak Mode

Communication Interface: CAN Bus (Compatible with RS-485)

Sensor Type: High Resolution Optical Sensor + Hall Sensor

Response Time: <2ms

1.3 Applicable Models

SIPLACE X series (X4i, X4s)

SIPLACE TX series

SIPLACE SX series

SIPLACE D series (adapter bracket required)

II. Mechanical structure and working principle

2.1 Core mechanical components

Drive system:

High torque stepper motor (1.8° step angle)

Precision planetary gearbox (reduction ratio 20:1)

Dual cam feeding mechanism

Guide system:

Reinforced dual linear guide rails (adjustable width)

Ceramic coated wear-resistant bushings

Segmented pressing device (8 pressure points)

Sensor system:

Main sensor: 5 million pixel CMOS optical sensor

Auxiliary sensor: Differential Hall sensor array

Ambient light anti-interference system

Tape handling system:

Automatic stripping device (adjustable force)

Waste tape collection guide

Anti-rebound mechanism

2.2 Working principle

Power transmission:

Controller sends pulse signal to stepper motor driver

Gearbox drives feeding cam

Precise positioning:

Main optical sensor reads material belt positioning hole

Hall sensor verifies mechanical position

Closed-loop control system real-time adjustment

Status monitoring:

Material belt remaining quantity detection (10 component warning in advance)

Component existence check

Feeding force monitoring

Data interaction:

Real-time upper material count

Store the latest 1000 alarm records

Support remote diagnosis

III. Performance characteristics and technical advantages

3.1 Core performance indicators

Feeding accuracy: ±0.03mm (@23±1℃)

Maximum feeding speed: 35 times/minute (24mm step)

Load capacity: supports 5kg tray

Temperature stability: ±0.01mm/℃

Repeat positioning accuracy: ±0.02mm (3σ)

3.2 Innovative technology highlights

Intelligent feeding control:

Adaptive learning algorithm (memorizes different material characteristics)

Automatic compensation for mechanical wear

Multiple sensor systems:

Triple redundant detection mechanism (optical + magnetic + mechanical)

Anti-pollution optical channel design

Modular design:

Quick-release feeding module (replacement time <2 minutes)

Independent replaceable sensor module

Energy efficiency optimization

Dynamic power regulation

Standby power consumption <1W

IV. Application scenarios and production line value

4.1 Typical application components

Large-size electrolytic capacitors (diameter ≥18mm)

Power modules (IGBT, MOSFET, etc.)

Large connectors

Transformer/inductor components

Heat dissipation module

4.2 Production line value

High precision guarantee:

Meet automotive electronics Grade-1 standard

Support all sizes above 01005 components

Efficiency improvement:

Replacement time <15 seconds

Intelligent early warning reduces unplanned downtime

Intelligent management:

Component traceability data collection

Predictive maintenance support

Cost optimization:

Energy saving 40% compared to pneumatic feeder

Maintenance interval extended by 3 times

V. Installation and operation guide

5.1 Installation process

Mechanical installation:

Align the guide groove of the feeder station of the placement machine

Push it into the automatic locking position (green indicator light on)

Electrical connection:

Connect 24VDC power supply (pay attention to polarity)

Insert CAN bus communication cable

System identification:

The placement machine automatically identifies the feeder type

Assign station number and load parameters

5.2 Operation points

Tape loading:

Open the pressing cover (press the blue buttons on both sides)

Ensure that the tape enters the guide groove straightly

Set the correct tape width (scale indication)

2 Parameter settings:

python

# Typical parameter setting example

{

"feed_pitch": 16, # Feeding pitch (mm)

"peel_force": 3, # Peeling force (N)

"sensitivity": 85, # Sensor sensitivity (%)

"pre_alarm": 10, # Number of early warnings

"speed_profile": 2 # Speed profile mode

}

Calibration process:

Perform automatic calibration (standard calibration tape required)

Manually verify the first 3 feeding positions

Save calibration parameters

VI. Maintenance system

6.1 Daily maintenance

Cleaning and maintenance:

Vacuum the guide area daily

Clean the sensor window with IPA every week (concentration 99.7%)

Lubrication management:

Lubricate after every 500,000 feedings:

Linear guide: Kluber ISOFLEX NBU15

Gear set: Molykote PG-65

6.2 Regular maintenance (quarterly)

Comprehensive inspection:

Measure rail wear (maximum allowable clearance 0.05mm)

Test motor current (rated value 1.2A±10%)

In-depth maintenance:

Replace worn bushing (if loose >0.1mm)

Calibrate sensor reference position

Performance verification:

Use standard test tape

Measure cumulative error after 100 continuous feeds

VII. Common fault diagnosis and treatment

7.1 Fault code analysis

Code Description Possible cause Solution

E721 Feeding timeout 1. Mechanical jamming

2. Motor failure 1. Check tape path

2. Test motor windings

E722 Sensor abnormality 1. Contamination

2. Wiring failure 1. Clean sensor

2. Check connector

E723 Communication interruption 1. Cable damage

2. Interface oxidation 1. Replace communication cable

2. Process contacts

E724 Position deviation is too large 1. Parameter error

2. Mechanical wear 1. Recalibrate

2. Check the gear set

E725 temperature warning 1. Overheating of the environment

2. Poor heat dissipation 1. Improve ventilation

2. Check the fan

7.2 Replacement of key components

Replacement of the feed module:

Remove 4 T8 screws

Disconnect the motor connector

Be careful to maintain the calibration position

Replacement of the sensor module:

Use anti-static tools

Perform optical calibration after replacement

Verify the alignment of the Hall sensor

VIII. Technology evolution and improvement suggestions

8.1 Version iteration

Gen1 (2015): Basic 72mm feeder

Gen2 (2018): Add intelligent sensing system

Gen3 (2021): Current model (CAN bus version)

8.2 Optimization suggestions

Parameter optimization:

Establish parameter templates for different material strips

Enable adaptive learning function

Spare parts strategy:

Standard key components:

Feeding gear set (P/N: 00141398)

Sensor module (P/N: 00141399)

Upgrade options:

High resolution version (5μm accuracy)

High temperature model (supports 85℃ environment)

IX. Comparison with other specifications of feeders

Parameters 72mm feeder 00141397 52mm feeder 32mm mechanical feeder

Maximum material strip width 72mm 52mm 32mm

Feeding accuracy ±0.03mm ±0.05mm ±0.1mm

Sensing function Multi-sensor system Basic sensor None

Maximum component height 15mm 10mm 8mm

Communication interface CAN bus RS-485 None

X. Summary and Outlook

ASM 72mm sensor feeder 00141397 represents the highest level of current large-size component feeding technology. Its core value lies in:

Ultra-large size processing capability: fills the technical gap of 50-100mm tape feeding

Military-grade reliability: MTBF>50,000 hours

High degree of intelligence: provides complete data interface for Industry 4.0

Future development direction:

Integrated AI visual assisted positioning

Wireless power supply and communication

Application of self-healing materials

Best practice recommendations:

Establish a preventive maintenance plan

Regularly back up parameter settings

Maintain 15% spare parts redundancy

This equipment is particularly suitable for:

New energy automotive electronics manufacturing

Industrial power module production

High-power LED packaging

Aerospace electronics assembly

Through standardized use and scientific maintenance, this feeder can ensure 7×24 hours of continuous and stable operation, providing reliable ultra-large component feeding solutions for high-end electronics manufacturing.