1. Tuotteen yleiskatsaus ja tekniset tiedot

1.1 Perusparametrit

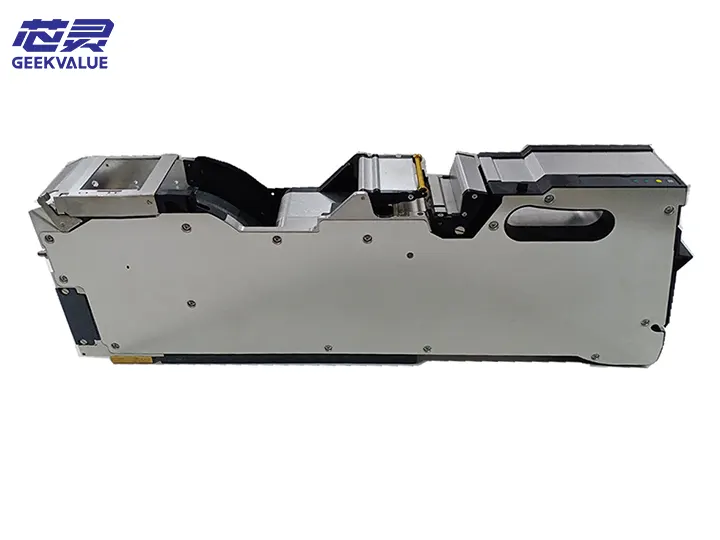

Malli: 00141397

Tyyppi: Sähköinen syöttölaite anturilla

Sovellettava nauhan leveys: 72 mm (yhteensopiva 68–72 mm:n kanssa)

Syöttöväli: 4/8/12/16/20/24 mm Ohjelmoitava

Komponentin enimmäiskorkeus: 15 mm

Nauhan paksuusalue: 0,3–2,0 mm

Mitat: 320 mm × 120 mm × 95 mm

Paino: 3,5 kg

Käyttöikä: ≥30 miljoonaa ruokintajaksoa

Suojaustaso: IP54

1.2 Sähköiset parametrit

Käyttöjännite: 24VDC±10%

Virrankulutus: 25 W normaalitilassa, 50 W huipputilassa

Viestintäliitäntä: CAN-väylä (RS-485-yhteensopiva)

Anturityyppi: Korkean resoluution optinen anturi + Hall-anturi

Vasteaika: <2 ms

1.3 Soveltuvat mallit

SIPLACE X -sarja (X4i, X4s)

SIPLACE TX -sarja

SIPLACE SX -sarja

SIPLACE D -sarja (sovitinkiinnike vaaditaan)

II. Mekaaninen rakenne ja toimintaperiaate

2.1 Keskeiset mekaaniset komponentit

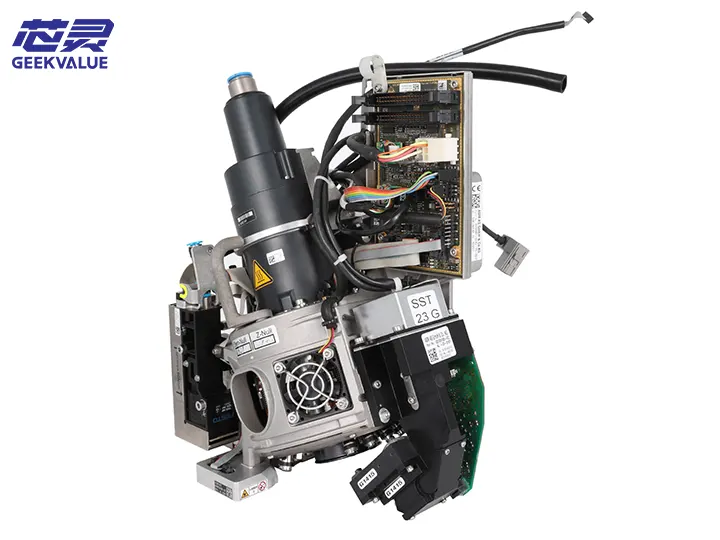

Käyttöjärjestelmä:

Suurivääntöinen askelmoottori (1,8° askelkulma)

Tarkkuusplaneettavaihteisto (alennussuhde 20:1)

Kaksoiskammi syöttömekanismi

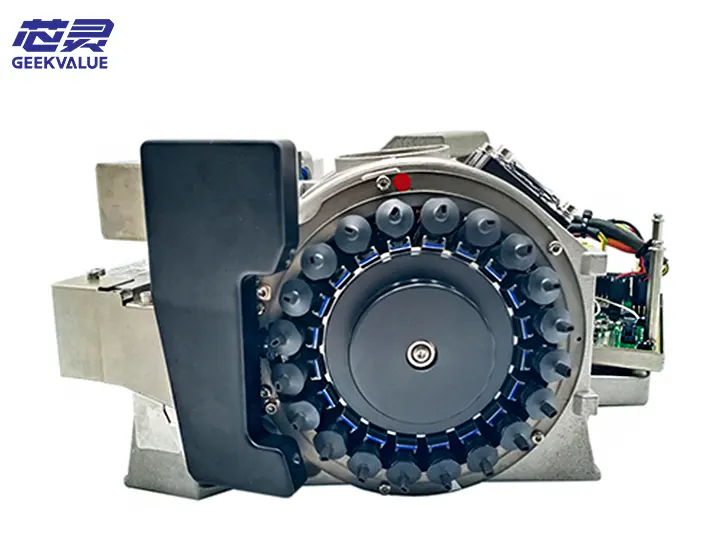

Opasjärjestelmä:

Vahvistetut kaksoislineaariset ohjauskiskot (säädettävä leveys)

Keraamisesti pinnoitetut kulutusta kestävät holkit

Segmentoitu puristuslaite (8 puristuspistettä)

Anturijärjestelmä:

Pääanturi: 5 miljoonan pikselin CMOS-optinen anturi

Apuanturi: Differentiaali-Hall-anturiryhmä

Ympäristön valon häiriönestojärjestelmä

Nauhan käsittelyjärjestelmä:

Automaattinen kuorintalaite (säädettävä voima)

Jätteenauhan keräysopas

Rebound-estomekanismi

2.2 Toimintaperiaate

Voimansiirto:

Ohjain lähettää pulssisignaalin askelmoottorin ajurille

Vaihteisto käyttää syöttökampaa

Tarkka paikannus:

Pääoptinen anturi lukee materiaalihihnan kohdistusreiän

Hall-anturi tarkistaa mekaanisen asennon

Suljetun silmukan ohjausjärjestelmän reaaliaikainen säätö

Tilanvalvonta:

Materiaalihihnan jäljellä olevan määrän tunnistus (10 komponentin varoitus etukäteen)

Komponentin olemassaolon tarkistus

Syöttövoiman valvonta

Datan vuorovaikutus:

Reaaliaikainen ylämateriaalimäärä

Tallenna 1000 viimeisintä hälytystietoa

Tukee etädiagnostiikkaa

III. Suorituskykyominaisuudet ja tekniset edut

3.1 Keskeiset suorituskykyindikaattorit

Syöttötarkkuus: ±0,03 mm (@23±1℃)

Suurin syöttönopeus: 35 kertaa minuutissa (24 mm:n askel)

Kantavuus: tukee 5 kg:n lokeroa

Lämpötilan vakaus: ±0,01 mm/℃

Toistopaikannustarkkuus: ±0,02 mm (3σ)

3.2 Innovatiiviset teknologian kohokohdat

Älykäs ruokinnan ohjaus:

Adaptiivinen oppimisalgoritmi (muistaa eri materiaalien ominaisuudet)

Automaattinen mekaanisen kulumisen kompensointi

Useita anturijärjestelmiä:

Kolminkertainen redundantti tunnistusmekanismi (optinen + magneettinen + mekaaninen)

Saastumisenesto-optinen kanavasuunnittelu

Modulaarinen rakenne:

Pikakiinnitteinen syöttömoduuli (vaihtoaika <2 minuuttia)

Itsenäinen vaihdettava anturimoduuli

Energiatehokkuuden optimointi

Dynaaminen tehonsäätö

Valmiustilan virrankulutus <1 W

IV. Sovellusskenaariot ja tuotantolinjan arvo

4.1 Tyypilliset sovelluskomponentit

Suurikokoiset elektrolyyttikondensaattorit (halkaisija ≥18 mm)

Tehomoduulit (IGBT, MOSFET jne.)

Suuret liittimet

Muuntajan/induktorin komponentit

Lämmönpoistomoduuli

4.2 Tuotantolinjan arvo

Korkean tarkkuuden takuu:

Täyttää autoelektroniikan Grade-1 -standardin

Tukee kaikkia yli 01005 kokoisia komponentteja

Tehokkuuden parantaminen:

Vaihtoaika <15 sekuntia

Älykäs ennakkovaroitus vähentää suunnittelemattomia seisokkeja

Älykäs hallinta:

Komponenttien jäljitettävyystietojen kerääminen

Ennakoiva kunnossapidon tuki

Kustannusten optimointi:

Energiansäästö 40 % pneumaattiseen syöttölaitteeseen verrattuna

Huoltoväli pidennetty kolminkertaiseksi

V. Asennus- ja käyttöopas

5.1 Asennusprosessi

Mekaaninen asennus:

Kohdista sijoittelukoneen syöttöaseman ohjausura

Työnnä se automaattiseen lukitusasentoon (vihreä merkkivalo palaa)

Sähköliitäntä:

Kytke 24 VDC:n virtalähde (huomioi napaisuus)

CAN-väylän tietoliikennekaapelin asettaminen

Järjestelmän tunnistus:

Asettelukone tunnistaa automaattisesti syöttölaitteen tyypin

Määritä aseman numero ja lataa parametrit

5.2 Toimintapisteet

Nauhan lataus:

Avaa painokansi (paina sinisiä painikkeita molemmilla puolilla)

Varmista, että teippi menee suoraan ohjausuraan

Aseta oikea nauhan leveys (asteikon ilmaisin)

2 Parametriasetukset:

python

# Tyypillinen esimerkki parametrien asettamisesta

{

"feed_pitch": 16, # Syöttökulman nousu (mm)

"peel_force": 3, # Kuorintavoima (N)

"herkkyys": 85, # Anturin herkkyys (%)

"pre_alarm": 10, # Ennakkovaroitusten määrä

"speed_profile": 2 # Nopeusprofiilitila

}

Kalibrointiprosessi:

Suorita automaattinen kalibrointi (vaatii vakiokalibrointinauhan)

Tarkista manuaalisesti kolme ensimmäistä ruokintakohtaa

Tallenna kalibrointiparametrit

VI. Kunnossapitojärjestelmä

6.1 Päivittäinen huolto

Puhdistus ja huolto:

Imuroi ohjainalue päivittäin

Puhdista anturi-ikkuna IPA:lla joka viikko (pitoisuus 99,7 %)

Voitelun hallinta:

Voitele 500 000 ruokinnan jälkeen:

Lineaariohjain: Kluber ISOFLEX NBU15

Vaihteisto: Molykote PG-65

6.2 Säännöllinen huolto (neljännesvuosittain)

Kattava tarkastus:

Mittaa kiskon kuluminen (suurin sallittu välys 0,05 mm)

Testimoottorin virta (nimellisarvo 1,2 A ± 10 %)

Perusteellinen huolto:

Vaihda kulunut holkki (jos löysä >0,1 mm)

Kalibroi anturin referenssiasento

Suorituskyvyn varmennus:

Käytä tavallista testinauhaa

Mittaa kumulatiivinen virhe 100 jatkuvan syötön jälkeen

VII. Yleisten vikojen diagnosointi ja hoito

7.1 Vikakoodien analyysi

Koodi Kuvaus Mahdollinen syy Ratkaisu

E721 Syöttöaikakatkaisu 1. Mekaaninen tukkeutuminen

2. Moottorivika 1. Tarkista teipin kulkureitti

2. Moottorin käämien testaus

E722 Anturin poikkeavuus 1. Kontaminaatio

2. Johdotusvika 1. Puhdista anturi

2. Tarkista liitin

E723 Viestintäkatkos 1. Kaapelivaurio

2. Liitännän hapettuminen 1. Vaihda tietoliikennekaapeli

2. Prosessiyhteydet

E724 Paikkapoikkeama on liian suuri 1. Parametrivirhe

2. Mekaaninen kuluminen 1. Kalibroi uudelleen

2. Tarkista vaihdelaatikko

E725 lämpötilavaroitus 1. Ympäristön ylikuumeneminen

2. Huono lämmönhukka 1. Paranna ilmanvaihtoa

2. Tarkista tuuletin

7.2 Keskeisten osien vaihtaminen

Syöttömoduulin vaihto:

Irrota 4 T8-ruuvia

Irrota moottorin liitin

Varmista kalibrointiasennon säilyttäminen

Anturimoduulin vaihto:

Käytä antistaattisia työkaluja

Suorita optinen kalibrointi vaihdon jälkeen

Tarkista Hall-anturin kohdistus

VIII. Teknologian kehitys ja parannusehdotukset

8.1 Versioiden iterointi

Gen1 (2015): Perus 72 mm:n syöttölaite

Gen2 (2018): Lisää älykäs tunnistusjärjestelmä

Gen3 (2021): Nykyinen malli (CAN-väyläversio)

8.2 Optimointiehdotukset

Parametrien optimointi:

Luo parametripohjia eri materiaalinauhoille

Ota mukautuva oppimistoiminto käyttöön

Varaosastrategia:

Vakio-osatekijät:

Syöttölaitesarja (P/N: 00141398)

Anturimoduuli (osanumero: 00141399)

Päivitysvaihtoehdot:

Korkean resoluution versio (5 μm tarkkuus)

Korkean lämpötilan malli (tukee 85 ℃ ympäristöä)

IX. Vertailu muihin syöttölaitteiden eritelmiin

Parametrit 72 mm:n syöttölaite 00141397 52 mm:n syöttölaite 32 mm:n mekaaninen syöttölaite

Materiaalinauhan enimmäisleveys 72 mm 52 mm 32 mm

Syöttötarkkuus ±0,03 mm ±0,05 mm ±0,1 mm

Tunnistustoiminto Monianturijärjestelmä Perusanturi Ei mitään

Komponentin enimmäiskorkeus 15 mm 10 mm 8 mm

Tiedonsiirtoliitäntä CAN-väylä RS-485 Ei mitään

X. Yhteenveto ja tulevaisuudennäkymät

ASM 72 mm:n anturisyötin 00141397 edustaa nykyisen suurten komponenttien syöttötekniikan korkeinta tasoa. Sen ydinarvot ovat:

Erittäin suurten kokojen käsittelykyky: täyttää 50–100 mm:n nauhansyötön teknisen aukon

Sotilasluokan luotettavuus: MTBF>50 000 tuntia

Korkea älykkyysaste: tarjoaa täydellisen dataliitännän Industry 4.0:lle

Tulevaisuuden kehityssuunta:

Integroitu tekoäly visuaalisesti avustettu paikannus

Langaton virtalähde ja tiedonsiirto

Itsekorjautuvien materiaalien käyttö

Parhaat käytännöt:

Laadi ennaltaehkäisevä huoltosuunnitelma

Varmuuskopioi parametriasetukset säännöllisesti

Säilytä 15 % varaosien redundanssi

Tämä laite sopii erityisesti:

Uuden energian autoelektroniikan valmistus

Teollisuuden tehomoduulien tuotanto

Suuritehoisten LED-pakkausten

Ilmailu- ja avaruuselektroniikan kokoonpano

Standardoidun käytön ja tieteellisen huollon ansiosta tämä syöttölaite voi varmistaa 7 × 24 tunnin jatkuvan ja vakaan toiminnan, tarjoten luotettavia erittäin suurten komponenttien syöttöratkaisuja huippuluokan elektroniikkavalmistukseen.