TRUMPF is a global leader in laser technology, known for producing precision equipment used in industries such as automotive, aerospace, medical devices, and electronics. Among the most frequently asked technical questions is: “What is the cutting tolerance of a TRUMPF laser?” Understanding the cutting tolerance is essential for ensuring product quality, accuracy, and consistency in laser cutting applications. This article will explore the technical definition of cutting tolerance, TRUMPF laser capabilities, and real-world factors that influence precision.

Understanding Cutting Tolerance in Laser Processing

Before diving into TRUMPF-specific specifications, it’s important to clarify what cutting tolerance means in the context of laser machines.

What Does Cutting Tolerance Refer To?

Cutting tolerance refers to the permissible deviation between the actual cut dimension and the desired design dimension. It is typically expressed in millimeters (mm) or micrometers (µm) and is a crucial factor in industries that require tight tolerances, such as electronics or medical device manufacturing.

Why is Tolerance Critical?

Fit and Assembly: In high-precision manufacturing, even a slight deviation can result in a poor fit.

Quality Control: Accurate tolerances reduce rejection rates and rework.

Consistency: Tight tolerances ensure that every part behaves identically under load, temperature, and time.

TRUMPF Laser Machines: Overview of Their Precision Capabilities

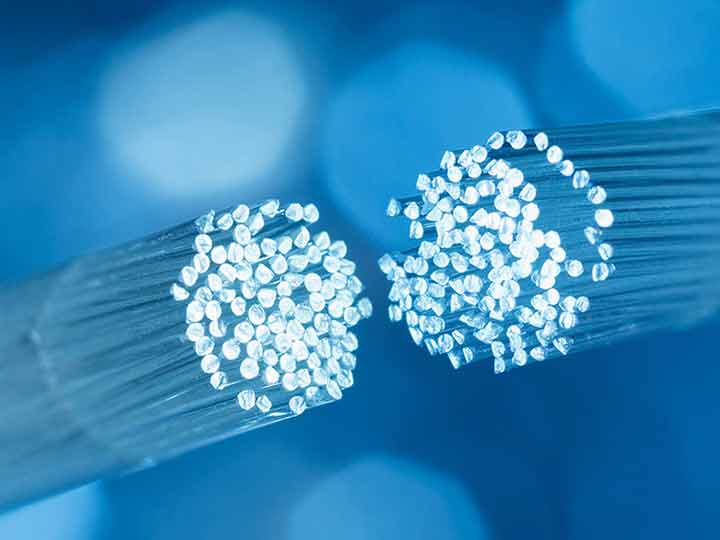

TRUMPF produces a wide range of laser systems, including CO2 lasers, solid-state lasers (like fiber and disk lasers), and 2D/3D laser cutting systems. Each type has slightly different tolerance capabilities.

TRUMPF Fiber Laser vs CO₂ Laser Tolerances

| Laser Type | Material Thickness | Typical Tolerance |

|---|---|---|

| TRUMPF Fiber Laser | 0.5–10 mm | ±0.05 to ±0.1 mm |

| TRUMPF CO₂ Laser | 1–25 mm | ±0.1 to ±0.2 mm |

| TRUMPF Solid-State | Up to 20 mm | ±0.03 to ±0.1 mm |

Note: The actual tolerance depends on material type, sheet thickness, laser parameters, and environmental conditions.

What Influences the Cutting Tolerance of TRUMPF Lasers?

Several variables can impact the final cutting accuracy of a TRUMPF laser machine. While the laser system provides high intrinsic precision, the real-world outcome depends on more than the machine itself.

Material Type and Thickness

Thin Sheets (≤1 mm): Typically allow for tighter tolerances due to reduced heat-affected zones and better focus control.

Thicker Sheets (>10 mm): May experience thermal expansion or dross buildup, slightly affecting precision.

Cutting Speed and Beam Focus

TRUMPF lasers support dynamic focus control, which allows the beam to adjust focus depth in real time. However:

High-speed cuts might compromise edge quality slightly.

Slow cuts produce cleaner edges but take longer.

Assist Gas Pressure and Type

Nitrogen is used for oxidation-free cuts and is ideal for tight tolerance parts.

Oxygen provides faster cuts but causes a heat-affected zone (HAZ), which can reduce accuracy slightly.

Machine Calibration and Maintenance

Even the best laser machines require regular calibration to ensure they maintain their factory-level precision. Factors include:

Alignment of optics

Nozzle condition

Beam centering

Environmental Conditions

Temperature fluctuations, vibrations, and humidity in the working environment can all impact cutting performance.

Typical Cutting Tolerances for Common Materials Using TRUMPF Lasers

| Material | Thickness (mm) | TRUMPF Laser Model | Expected Tolerance |

|---|---|---|---|

| Stainless Steel | 1.0 mm | TruLaser 5030 Fiber | ±0.03 mm |

| Aluminum | 3.0 mm | TruLaser 3030 Fiber | ±0.05 mm |

| Mild Steel | 10 mm | TruLaser 5060 CO₂ | ±0.1 mm |

| Titanium Alloy | 2.0 mm | TruLaser Cell 3000 | ±0.04 mm |

| Copper | 1.5 mm | TruLaser 5030 Fiber | ±0.05 mm |

How TRUMPF Achieves High Cutting Tolerances

TRUMPF invests heavily in technological innovations to enhance cutting precision. Here’s how they ensure industry-leading tolerances:

High-Resolution Encoders

Their machines use linear motor drives and high-resolution optical encoders that track movement within micrometers.

Smart Beam Control

Advanced beam modulation technologies, like BrightLine fiber, ensure cleaner edges and minimal tapering on thicker materials.

Adaptive Power Control

TRUMPF lasers can dynamically modulate power based on the material and geometry of the cut, improving both quality and consistency.

EdgeLine Bevel and Highspeed Eco Features

EdgeLine Bevel enables angled cuts and chamfers directly within the same machine.

Highspeed Eco reduces gas usage while improving cutting speed—without sacrificing accuracy.

Applications Where Cutting Tolerance Is Critical

Some industries depend on TRUMPF's cutting precision to meet strict quality and engineering standards.

Aerospace Components

Tolerances are critical due to aerodynamic and structural requirements.

TRUMPF lasers are commonly used for titanium and Inconel parts.

Medical Devices

Devices like surgical instruments and implantable components require micron-level precision.

TRUMPF’s fine laser cutting is ideal for stainless steel and nitinol.

Electronics and PCB Manufacturing

Thin copper, aluminum, or polyimide layers need burr-free and accurate cuts.

Tolerance must be within ±0.02 mm in some micro applications.

Automotive Sheet Metal

Chassis and structural parts benefit from TRUMPF's ability to maintain tight tolerances even during batch production.

How to Improve Cutting Tolerance in Practice

Even if a TRUMPF laser is rated for ±0.03 mm, how you prepare and operate the machine will ultimately determine whether you achieve it.

Use Proper Clamping and Fixturing

Ensure the workpiece is held flat and stable during cutting to avoid vibration or warping.

Select the Correct Lens and Nozzle

Using the right combination of focal length lens and nozzle diameter ensures proper focus and gas flow for tighter tolerances.

Perform Regular Machine Maintenance

Calibrate motion systems and optics monthly

Check nozzle alignment and beam quality

Update firmware to take advantage of the latest precision features

Leverage TRUMPF Smart Factory Features

TRUMPF’s Smart Factory solutions include automatic sheet detection, part tracking, and AI-based monitoring to reduce human error and improve consistency.

Conclusion: Precision That Meets Industry Standards

So, what is the cutting tolerance of a TRUMPF laser? The answer depends on the model, material, and process parameters, but generally, TRUMPF laser systems offer tolerances between ±0.03 mm to ±0.2 mm. This precision level makes them ideal for a wide range of high-performance applications across various industries.

When configured correctly and maintained properly, a TRUMPF laser cutting machine can reliably produce parts with exceptional dimensional accuracy, minimal edge taper, and superior surface quality.

Whether you're manufacturing microelectronics or large steel enclosures, TRUMPF lasers provide the cutting precision required in today’s competitive industrial environment.