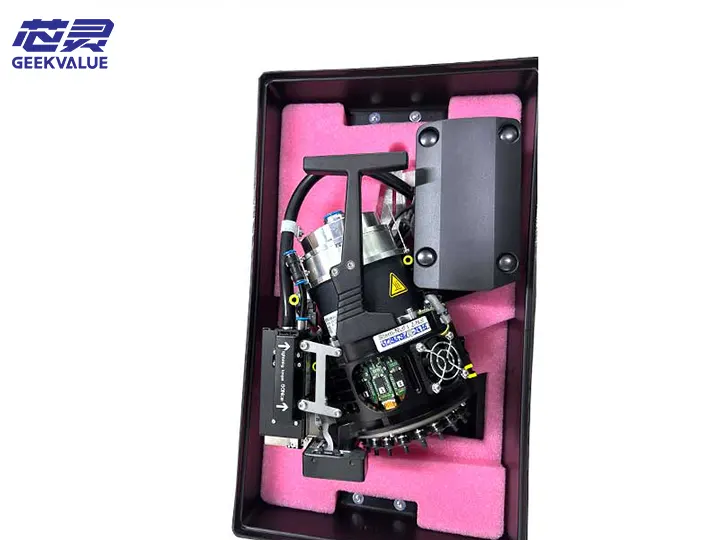

The following is a comprehensive introduction to the ASM SMT machine CP20P2 patch head vacuum generator 03136795, covering its functions, structure, working principle, application scenarios, maintenance and troubleshooting, etc.:

1. Aperçu de base

Model: 03136795

Purpose: A vacuum generator designed specifically for the ASM SIPLACE CP20P2 patch head, used to generate negative pressure (vacuum) to adsorb and mount electronic components.

Applicable equipment: ASM SIPLACE CP20P2 high-speed patch head (commonly used in X series or D series patch machines).

Core function: Ensure that components are stably adsorbed during picking, transportation and placement to avoid falling or offset.

2. Fonctions principales

Vacuum generation: Convert compressed air (positive pressure) into negative pressure to quickly adsorb components.

Pressure adjustment: The vacuum degree can be adjusted according to the size of the component (such as 0201 small components or large ICs).

Fast response: supports high-speed movement of the patch head (such as 30,000+ CPH) to achieve millisecond-level pick-and-place.

Multi-channel control: Some models support independent control of the vacuum path of multiple nozzles.

3. Caractéristiques techniques

High-efficiency design:

Adopting the Venturi principle (Venturi effect), a stable vacuum can be generated without a mechanical pump.

Low gas consumption, reducing compressed air consumption and reducing production costs.

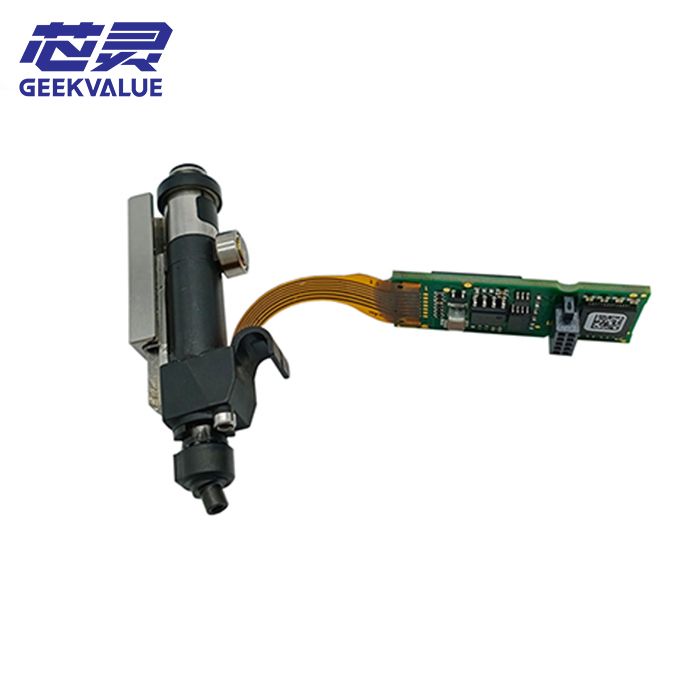

Compact structure: Integrated design, suitable for the narrow space of the CP20P2 patch head.

Durability:

Material is wear-resistant (such as aluminum alloy or engineering plastic).

Withstands frequent start-stop and vibration.

Compatibility: Supports a variety of nozzle types (such as Φ0.7mm~Φ2.0mm).

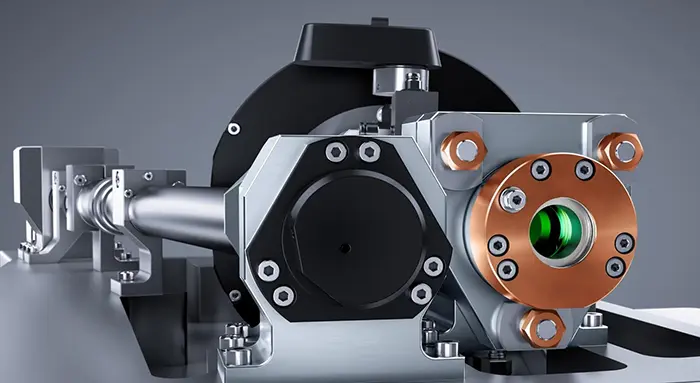

4. Structure and composition

Description fonctionnelle du composant

Air inlet Connects to the compressed air pipeline (typical pressure: 0.4~0.6 MPa).

Vacuum cavity Generates negative pressure by high-speed airflow through a narrow channel.

Vacuum output port Connect the nozzle to adsorb components.

Silencer Reduces airflow noise (integrated in some models).

Filter unit Optional configuration to prevent dust from entering the vacuum line (protect components and nozzles).

5. Working principle

Compressed air input: High-pressure airflow enters the generator from the air inlet.

Venturi effect: The airflow speed increases when passing through a narrow cavity, forming a negative pressure in the vacuum chamber.

Component adsorption: Negative pressure grabs the component through the nozzle.

Release component: Cut off the airflow or switch to positive pressure, and the component is separated from the nozzle.

6. Application scenarios

High-speed placement: Suitable for precision placement of components such as resistors, capacitors, QFN, BGA, etc.

Flexible circuit board (FPC) production: The vacuum degree can be adjusted to avoid damaging thin boards.

Mixed placement of multiple types of components: The vacuum strength of different nozzles is controlled by software.

7. Maintenance and troubleshooting

Common problems

Insufficient vacuum:

Reason: air path blockage, nozzle wear, low compressed air pressure.

Solution: Clean the gas line, replace the suction nozzle or adjust the gas pressure.

Leakage:

Cause: The seal ring is aged and the pipeline is broken.

Solution: Replace the seal (such as O-ring).

Response delay:

Cause: Solenoid valve failure or too long gas line.

Maintenance suggestions

Inspection quotidienne :

Clean the suction nozzle and vacuum pipeline to avoid solder paste or dust accumulation.

Check the gas pressure stability (recommended 0.5 MPa ± 10%).

Entretien régulier :

Disassemble and clean the vacuum chamber every 3 months.

Replace worn seals (refer to ASM maintenance manual).

8. Replacement and installation steps

Power off and stop: Turn off the equipment and release the residual gas pressure.

Disassemble the old generator: Disconnect the gas line and fixing screws, and pull it out carefully.

Install new parts:

Align the interface and make sure the seal ring is intact.

Tighten the screws (avoid over-tightening to avoid deformation).

Test:

Run the vacuum calibration program after turning on the machine.

Test the adsorption stability with standard components.

9. Technical parameters (example)

Parameter Value/description

Working air pressure 0.4~0.6 MPa

Vacuum ≥-70 kPa (adjusted according to component weight)

Response time <10 ms

Interface type G1/8 inch thread or quick-connect connector

Ambient temperature 5~40°C

10. Replacement and Upgrade

Original accessories: It is recommended to give priority to ASM original models (03136795) to ensure compatibility.

Third-party replacement: The gas line interface, vacuum performance and size matching need to be verified.

Upgrade options: New vacuum generators may support intelligent pressure feedback or energy-saving mode, please consult ASM technical support.

11. Notes

Do not use compressed air containing oil or moisture to avoid contaminating components or blocking the gas line.

When mounting ultra-small components (such as 01005), the vacuum degree needs to be lowered to prevent components from flying.

Spare parts need to be dust-proof and moisture-proof to extend service life