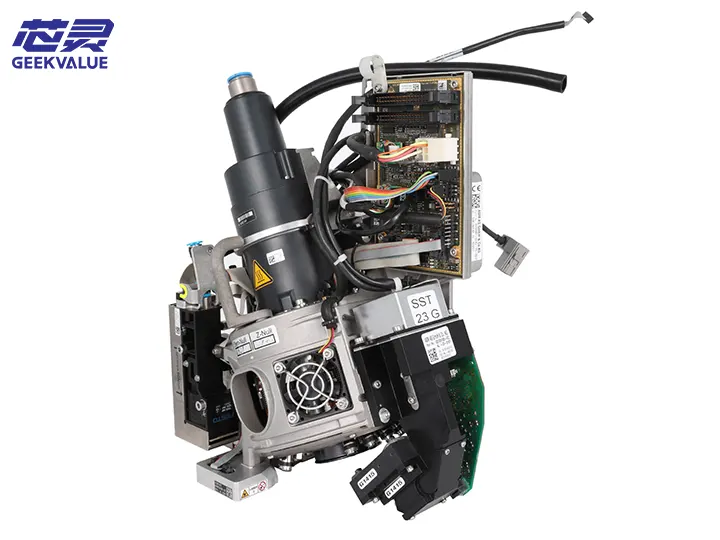

ASM SMT Component Camera No. 48 (Model: 03131695) Comprehensive Introduction

1. Specifications

Item Detailed Parameters

Model 03131695 (Component Camera No. 48)

Applicable Equipment ASM SIPLACE Series SMT Machines (such as X4S, TX, D Series)

Camera Type High-speed and high-resolution industrial camera (CMOS sensor)

Resolution 5MP (supports resolution up to 0.02mm/pixel)

Frame rate 60-120fps (supports ultra-high-speed shooting)

Field of view 15mm×15mm (can identify 01005 to large IC components)

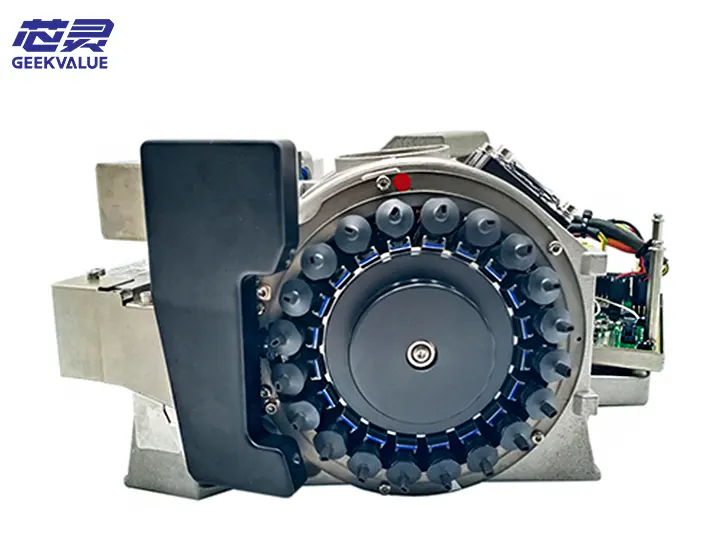

Light source system Three-color adjustable ring LED (red/blue/white light independent control)

Communication interface GigE Vision (supports PoE power supply)

Protection level IP54 (dust-proof and splash-proof design)

Operating temperature 0-45℃ (with temperature compensation function)

2. Functions and effects

Core functions:

Precision component identification: supports high-speed imaging of large components from 01005 to 30mm

Three-dimensional feature detection: realize component coplanarity detection through multi-angle light sources

Intelligent classification: AI algorithm automatically identifies component polarity, defects, etc.

Dynamic compensation: real-time feedback of mounting offset data

Typical applications:

Ultra-precision component mounting (01005/0201)

Positioning of special-shaped components (connectors, shielding covers)

High-precision BGA/QFN mounting

3. Technical features

Intelligent optical system:

Patented polarized light technology to eliminate reflective interference

16 levels of adjustable brightness to adapt to various surface materials

High-speed image processing:

Equipped with a dedicated DSP chip, processing delay <2ms

Supports parallel processing of multiple ROIs (regions of interest)

Enhanced durable design:

Seismic structure (can withstand 5G vibration)

Modular design, key components can be quickly replaced

4. Common faults and handling

Fault code Phenomenon description Possible cause Solution

E4801 Image blur Lens contamination/focal length offset 1. Clean the lens

2. Recalibrate

E4802 Communication interruption Network cable failure/interface oxidation 1. Replace Cat6 network cable

2. Check PoE power supply

E4803 Light source abnormality LED driver failure 1. Restart the system

2. Replace the light source module

E4804 Calibration failed Calibration board contamination 1. Clean the calibration board

2. Reinitialize parameters

5. Maintenance plan

Daily maintenance:

Daily:

Check lens cleanliness (use a special cleaning rod)

Confirm light source uniformity

Weekly:

Clean the camera heat dissipation holes

Check data cable connection status

Regular maintenance:

Monthly:

Perform optical calibration (use NIST certified calibration board)

Check mechanical installation tightness

Quarterly:

Replace dust filter

Fully inspect the optical system

6. Maintenance strategy

Graded maintenance plan:

Primary maintenance:

Replace wearing parts (dust cover, connector, etc.)

Firmware upgrade (through ASM Service Hub)

Intermediate repair:

Optical component replacement (special calibration tools required)

Light source module repair (spectrometer required)

In-depth repair:

Sensor replacement (dust-free environment required)

Mainboard-level repair (return to factory for processing)

Maintenance precautions:

Original calibration tools must be used

Odd-free adjustment of optical component screws is prohibited

Full-process calibration is required after repair

7. Upgrade selection suggestions

Standard version: 03131695 (basic model)

Enhanced version: 03131695-PRO (supports 3D detection)

High-speed version: 03131695-HS (frame rate increased to 200fps)

8. Technology development trends

AI integration: new firmware supporting deep learning is coming soon

5G connection: next-generation models will support remote diagnosis

Multispectral detection: increase infrared imaging capabilities

9. Usage suggestions

It is recommended to use with ASM original nozzles

Back up camera parameters regularly

Establish a complete maintenance log

10 Summary

ASM Component Camera No. 48 (03131695) represents the top technology of current SMT vision system, and its outstanding features are:

Industry-leading 5MP resolution

Intelligent adaptive light source system

Military-grade durability design

Complete fault self-diagnosis function

Through standardized maintenance and scientific repair strategies, the equipment can always maintain the best performance. For production lines with high-precision placement requirements, it is recommended to perform professional-level calibration maintenance every 6 months