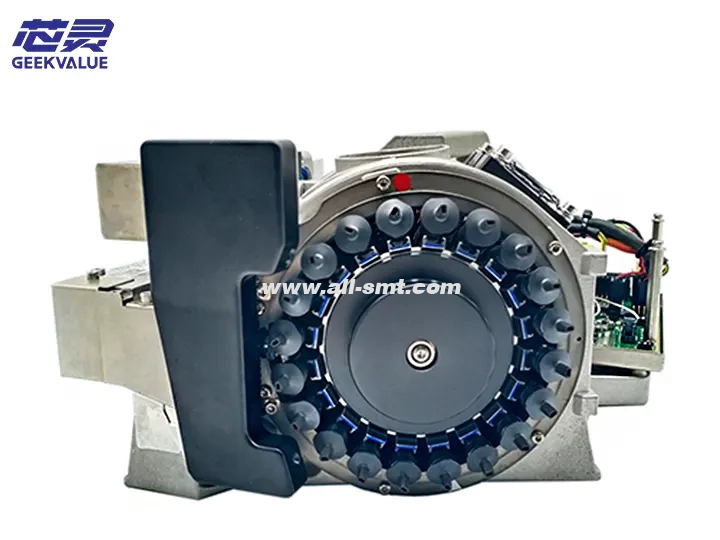

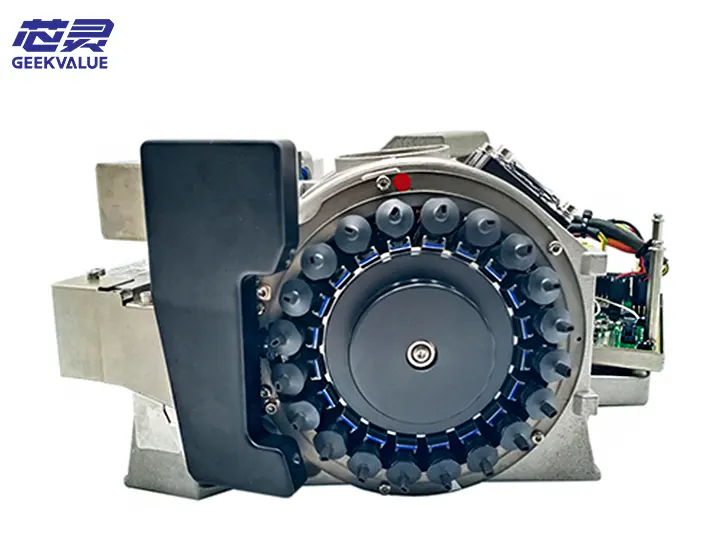

The CP20P work head (part number 03091157) is a key placement module designed by ASM (now Siemens Electronic Assembly Systems) for high-precision placement machines. It is widely used in SMT production lines and is suitable for precise placement of components from 0201 to large ICs (such as QFP, BGA, etc.). The work head is known for its high speed, high precision and stability, and is one of the core components of the ASM CP series placement machines.

2. Structural composition

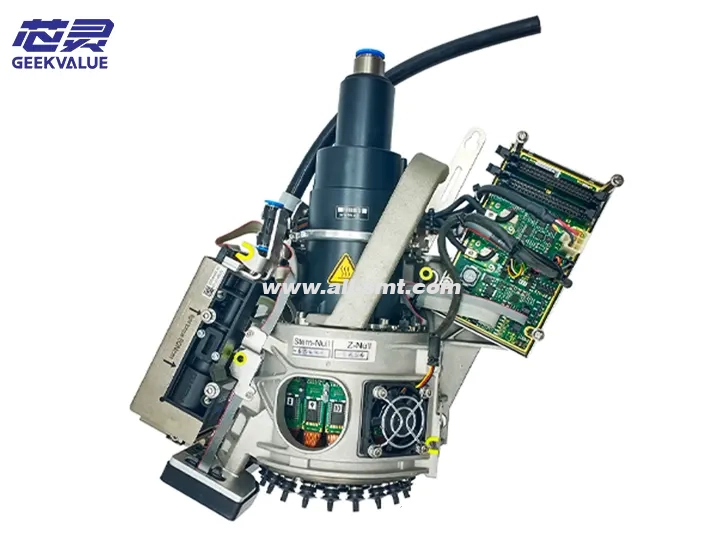

1. Mechanical structure

Component Functional description

Spindle system High-precision servo motor + ball screw drive, control Z-axis movement, ensure stable placement pressure

Placement head module 12 nozzles/16 nozzles optional, support quick replacement, adapt to different component sizes

Vacuum system Independent vacuum channel design, equipped with vacuum sensor, real-time monitoring of picking and placement status

Centering mechanism Integrated optical alignment (optional) or mechanical alignment to ensure precise alignment of component pins with PCB pads

θ-axis rotation system High-resolution servo motor controls component angle rotation (±180°), with an accuracy of up to ±0.1°

2. Electronic system

Component Functional description

Encoder system High-resolution linear/rotary encoder, providing nanometer-level position feedback

Sensor system Including vacuum sensor, height sensor, temperature sensor, real-time monitoring of working status

Control board Dedicated FPGA/DSP control circuit, processing motion control, signal acquisition and communication

3. Auxiliary system

Component Functional description

Nozzle replacement device Automatic or semi-automatic nozzle replacement mechanism, supports different nozzle types (such as 03091157 standard nozzle)

Cleaning system Optional nozzle automatic cleaning module to reduce the impact of residues

Lubrication system Automatic lubrication of guide rails and screws to reduce mechanical wear

III. Technical specifications (specific parameters for material number 03091157)

Parameters Specifications

Applicable component range 0201~55mm×55mm (such as 0402, 0603, SOIC, QFP, BGA, etc.)

Placement accuracy ±25μm (Cpk≥1.0, based on IPC standard)

Placement speed Up to 30,000CPH (depending on component complexity and machine configuration)

Z-axis travel 0~25mm (programmable control placement pressure)

Vacuum pressure -70kPa~-90kPa (adjustable, equipped with vacuum flow monitoring)

Working temperature 15~35℃ (constant temperature workshop environment required)

Weight About 3.5kg (including standard nozzle set)

IV. Core advantages and features

1. Balance of high precision and high speed

Adopt direct drive technology (beltless design) to reduce mechanical transmission error and achieve ±25μm placement accuracy.

Dynamic Z-axis control: Adapt to PCB warping and component thickness changes to avoid crushing pads.

2. Modular design

Supports quick replacement of nozzle sets (part number 03091157 is compatible with a variety of nozzle types), and line change time is less than 2 minutes.

Can be disassembled and repaired independently to reduce downtime costs.

3. Intelligent monitoring function

Real-time vacuum detection: automatic retry or alarm when picking fails (such as error code E401).

Temperature monitoring: prevent motor overheating (alarm E603).

4. Wide compatibility

Support ASM CP20P series placement machines (such as SIPLACE SX series), and adapt to a variety of feeders (belt, tray, vibration feeder).

V. Common errors and troubleshooting

1. Mechanical failure

Error code Fault phenomenon Possible cause Solution

E101 Z-axis movement exceeds the limit Mechanical limit offset/servo parameter error Recalibrate the Z-axis origin/check the servo drive settings

E205 Nozzle rod stuck Foreign matter blocking/inadequate lubrication Clean the guide rail and lubricate manually (use ASM specified grease)

2. Vacuum system failure

Error code Fault phenomenon Possible cause Solution

E401 Vacuum establishment failed Nozzle blockage/vacuum pump failure Clean or replace the nozzle and check the sealing of the vacuum pipeline

E402 Vacuum leakage O-ring aging/trachea rupture Replace the sealing ring (part number 03091157-002)

3. Sensor/electronic failure

Error code Fault phenomenon Possible cause Solution

E502 Encoder signal loss Loose cable/electromagnetic interference Replug the encoder cable and check the integrity of the shielding layer

E603 Too high temperature Poor heat dissipation/motor overload Clean the fan and reduce the continuous placement speed

VI. Maintenance Guide

1. Daily Maintenance

Cleaning the nozzle: Wipe with dust-free cloth + IPA every 4 hours to prevent flux residue.

Check the vacuum filter: Clean or replace weekly (Part No. 03091157-003).

2. Monthly Maintenance

Lubricate moving parts: Apply ASM special grease (Part No. 03091157-LUB) to the guide rails and lead screws.

Calibrate sensors: Perform vacuum sensor and height sensor calibration through machine software.

3. Annual Overhaul

Replace wear parts: including O-rings (Part No. 03091157-002) and nozzle rod bearings.

Comprehensive accuracy calibration: Recalibrate the mounting position and angle using a standard calibration plate.

VII. Repair and spare parts management

Recommended spare parts:

Nozzle set (part number 03091157-NZ)

Vacuum generator (part number 03091157-VAC)

Encoder cable (part number 03091157-ENC)

Repair process:

Disassemble the work head after power off.

Use a multimeter to detect the sensor and motor resistance.

Replace the faulty module (if the control board requires original technical support).

VIII. Summary

The ASM CP20P work head (03091157) is an ideal choice for medium and high-speed SMT production lines due to its high precision, modular design and intelligent monitoring capabilities. Through standardized maintenance and timely troubleshooting, it can ensure long-term stable operation and maintain the placement yield above 99.95%. For key spare parts (such as vacuum components and encoders), it is recommended to reserve original models to shorten downtime