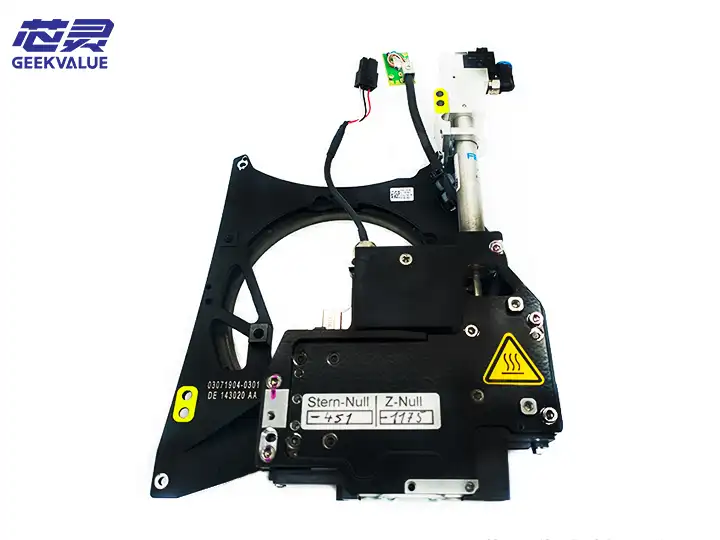

I-ASM SMT 2X8MM Feeder ngaphandle kweSensor 00141479 yinxalenye ephambili kwinkqubo yokutya ye-ASM SMT. Oku kulandelayo yintshayelelo ebanzi kuyo:

Ulwazi olusisiseko

Umzekelo: 00141479, ungowe-2X8MM Feeder series ye-ASM SMT, efanelekileyo yokucubungula iiteyipu eziphathekayo kunye nobubanzi be-8MM, kwaye ineendlela ezimbini zokutya, ezinokubonelela ngezinto ezimbini ezahlukeneyo ngexesha elifanayo ukuphucula ukusebenza kwemveliso.

Uhlobo: Isondlo ngaphandle koluvo. Xa kuthelekiswa ne-feeder kunye nenzwa, ayinayo umsebenzi wokufumanisa ngokuzenzekelayo inani eliseleyo lezinto eziphathekayo, indawo yecandelo, njl., Kwaye ifuna ukuba abaqhubi babeke iliso kwaye balawule ngezinye iindlela.

Uyilo loLwakhiwo

Indlela yokuguqula: isetyenziselwa ukufakela kunye nokulungisa iteyiphu yezinto ezinokwakheka kwe-reel, kunye nokuqhuba iteyiphu yezinto eziphathekayo ukuba ikhutshwe ngokuthe ngcembe nge-shaft ejikelezayo.

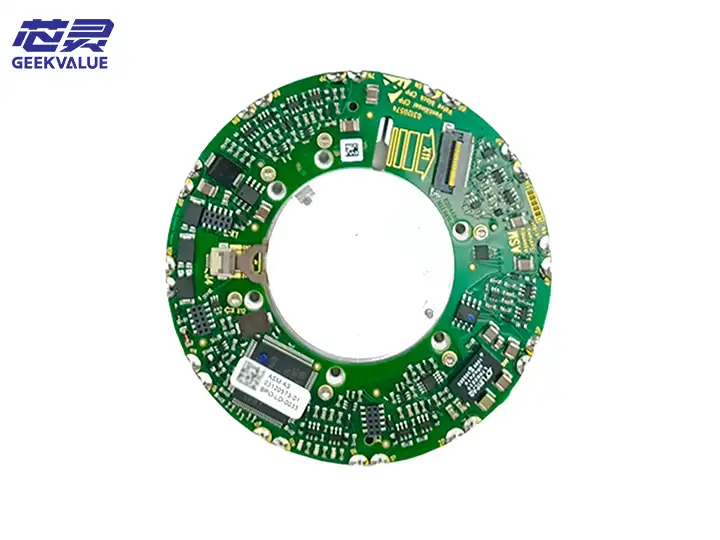

Inkqubo yokuhanjiswa: ngokuqhelekileyo iqulunqwe isethi yegiya kunye ne-stepper motor, enokulawula ngokuchanekileyo inyathelo lokutya le-tape yezinto eziphathekayo ukuqinisekisa ukuba amacandelo ahanjiswa ngokuchanekileyo kwindawo yokuthatha.

Isixhobo sokucofa iteyiphu: lungisa iteyiphu kwindawo yokutya ukuze uthintele iteyiphu ukuba ingaguquki okanye ishukume ngexesha lenkqubo yokuhambisa. Ngelo xesha, kukho ipleyiti yokwahlula ekupheleni kwe-tape yokwahlula i-tape ephezulu kwisiseko se-tape ukwenzela ukuba intloko ye-patch ikwazi ukuthabatha amacandelo kakuhle.

Ivili lokuthatha iteyiphu: uxanduva lokuqokelela iteyiphu engaphezulu exotshiweyo ukugcina itheyiphu icocekile kwaye ihlelekile.

Umgaqo wokusebenza

Ufakelo lweteyiphu kunye nokubeka indawo: faka iteyiphu ye-reel enamalungu e-elektroniki kwindlela yokudibanisa ye-feeder, kunye ne-tape ingena kwi-feed trough ngokusebenzisa isixhobo sokucofa. I-tape ephezulu ihlukaniswe kwisiseko se-tape ngokusebenzisa ipleyiti yokwahlukana kwaye igxininiswe kwivili lokuthatha. Umngxuma ohambelanayo kwisiseko se-tape ufakwe kwi-synchronous gear, kwaye intloko ye-tape ifikelela ekupheleni kwangaphandle kwe-feeder. Oku kugqiba ukufakela kunye nokumiswa kwangaphambili kweteyiphu.

Ukuhanjiswa kwecandelo: Xa umatshini we-SMT usebenza, intloko ye-SMT ithatha amacandelo ngokweprogram, kwaye inika umqondiso womatshini kwi-handle ngokusebenzisa "i-roller feed", ukwenzela ukuba isondo elihambelanayo lijikeleze i-angle, liqhube ibhanti lezinto eziphathekayo phambili, kwaye lithumela icandelo elilandelayo kwindawo yokutya, elinde ukuba intloko ye-SMT ithathe.

Imiyalelo

Faka i-feeder: Qala ucoce indawo yokudibanisa phakathi kwe-feeder kunye nomatshini we-SMT ukuqinisekisa ukuba akukho luthuli kunye nezinto zangaphandle. Emva koko faka i-feeder kwindawo ehambelanayo yomatshini we-SMT kwaye uqinisekise ukuba ukufakwa kuzinzile. Ngokuxhomekeke kwisithuba samacandelo, umgama wothumelo we-feeder unokufuna ukulungiswa.

Faka iteyiphu: Vula isigqubuthelo soxinzelelo kunye nomzila wesikhokelo setape kwiteyiphu ye-feeder, kwaye ubeke i-reel yempahla kwi-reel rack ye-feeder. Dlulisa umqulu ophezulu kunye nokuhanjiswa kwezinto eziphathekayo kwi-groove yesikhokelo sebhanti kunye nesakhelo esiphambili, vula umqulu ophezulu wokugubungela ukusuka ekupheleni kwentloko yebhanti yezinto eziphathekayo kude kube yinto efunxwayo, beka umqulu wokuhambisa kwi-slot yesitimela sesikhokelo, yenza i-sprocket clamp i-groove ehambayo yomqulu wothumelo, ukudiliza ibhanti lezinto eziphathekayo kwi-rail yesikhokelo, uqinisekise ukuba i-rolling i-rail, i-roll, i-roll, i-rail yokuhambisa i-flat kunye ne-rolling roll. ngokuqhelekileyo ibambekile kwi-sprocket. Okokugqibela, xhoma isigqubuthelo esingaphezulu esizinzileyo nesahluliweyo phakathi kwegiya kunye nesixhobo sokwenza.

Ukulungiswa kwe-Feeder: Emva kofakelo, qhuba uvavanyo lokujonga ukuhanjiswa kwezinto kwi-feeder. Ukuba kukho nakuphi na ukungaqhelekanga, lungisa indawo ye-feeder kunye nezinto eziphathekayo ngexesha ukuze uqinisekise ukuchaneka kunye nokuzinza kokunyuka.

Isondlo

Ukucoca rhoqo: Sebenzisa i-brush ukucoca izinto ezishiyekileyo kunye nezinye izinto zangaphandle kwi-feeder yonke imihla, ngokukodwa inxalenye ye-sprocket, yigcine icocekile ukuphepha ukungcola okuchaphazela ukuchaneka kokuhanjiswa kwebhanti yezinto eziphathekayo.

Hlola amacandelo: Khangela ukuba zonke izikrufu kwi-feeder zikhululekile nyanga zonke, kwaye wongeze ioli yokuthambisa ehambelanayo kwiindawo ezisasazwa rhoqo ukunciphisa ukuguga kunye nokuqinisekisa ukusebenza okuqhelekileyo kwe-feeder.

Gwema ukungqubana: Ngexesha lokuchithwa kunye nokusetyenziswa, i-feeder kufuneka iphathwe ngononophelo. Akuvunyelwe ukugcina i-feeder kwindawo yamagnetic ukuphepha ukungqubana nezinye izinto ukuthintela umonakalo okanye ukuguqulwa kwamacandelo okubangelwa ukungqubana, okuchaphazela ukuchaneka kwayo kunye nokusebenza kwayo.

Imeko yesicelo

Isetyenziswa kakhulu kumgca wemveliso yokubeka isantya esiphezulu soomatshini bokubeka i-ASM, ilungele ukubekwa kwamacandelo ahlukeneyo e-elektroniki, njenge-resistors, i-capacitors, i-diode, i-transistors kunye nezinye iinqununu ezincinci zamaphepha. Isetyenziswa kakhulu kwishishini lokuvelisa i-elektroniki, kubandakanya ukuveliswa kweemveliso ezahlukeneyo ze-elektroniki ezinjengeefowuni eziphathwayo, iikhompyuter, iitafile, izixhobo zasekhaya, njl.

Lo mxhasi, kunye nenkqubo yokuhanjiswa kwe-high-chaneke kunye nomthamo wokutya ozinzileyo, unikeza isiqinisekiso esiqinileyo sokubekwa ngokufanelekileyo kunye nokuchanekileyo kokubekwa koomatshini be-ASM, kwaye sesinye sezixhobo ezibalulekileyo kwiinkampani zokuvelisa i-elektroniki ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Nangona kunjalo, ngexesha lokusetyenziswa, abaqhubi kufuneka balandele ngokungqongqo iinkqubo zokusebenza zofakelo, ukuthunyelwa kunye nokugcinwa ukuze badlale ngokupheleleyo kwiinzuzo zayo zokusebenza.