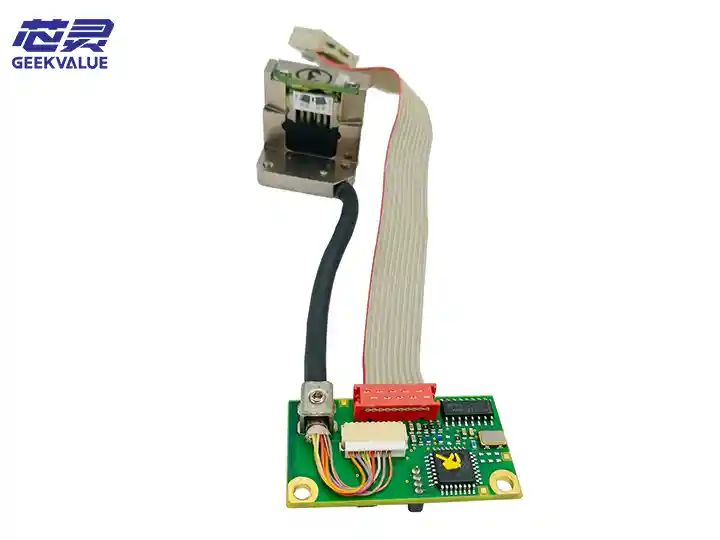

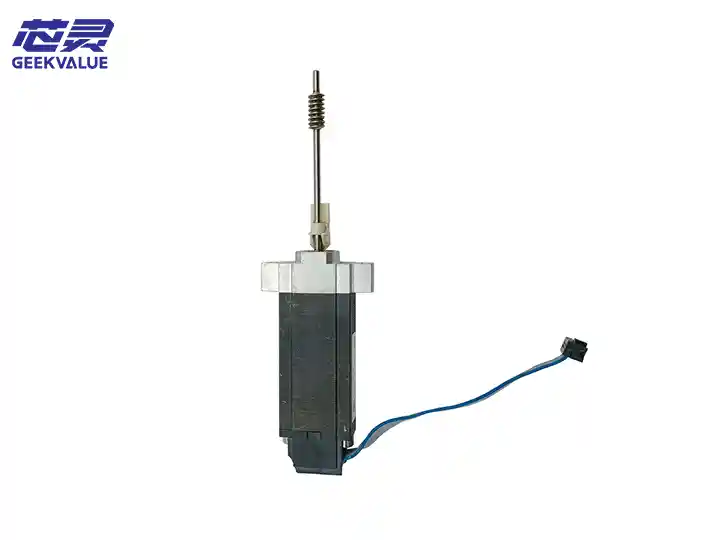

Siemens SMT machine 16mm feeder without sensor (model: 00141372) is a mechanical feeding device designed for 16mm wide tapes, suitable for stable feeding of various medium and large SMD components. The feeder adopts a purely mechanical transmission structure, with the characteristics of simple structure, easy maintenance and low cost. It is an economical and reliable feeding solution in SMT production lines.

2. Product features

1. Mechanical structure features

Heavy feeding mechanism: reinforced steel ratchet and guide rails, which can stably convey heavier tapes

Wide tape adaptation: specially optimized for 16mm tapes (compatible with 12-16mm)

Simple adjustment system: manually adjust the width of the tape guide groove

Durable design: key components are made of hardened steel with strong wear resistance

2. Operational features

Pure mechanical operation: no electrical connection required, ready to use

Quick material change design: one-hand operation of the material belt release lever

Visual positioning assistance: engraved with clear position scale marks

III. Core functions

Stable feeding: accurate delivery of 16mm pitch material belt (standard step 4/8mm)

Material belt guide: adjustable guide groove ensures linear movement of the material belt

Anti-recoil design: built-in anti-backward mechanism prevents the material belt from rebounding

Quick change: simple locking mechanism realizes material change in seconds

IV. Production line function

Economic feeding solution: provides cost-effective feeding method for large components

Reliability guarantee : Mechanical structure ensures long-term stable operation

Backup option: As an emergency backup device for sensor feeders

Wide compatibility: Suitable for larger components such as LEDs and connectors

V. Product advantages

High cost-effectiveness: 40-60% lower price than electronic feeders

Maintenance-free design: No electronic components, almost no daily maintenance

Strong environmental adaptability: Can work stably in harsh environments such as dust and oil mist

Extremely long life: The life of key components can reach more than 15 million times

Plug and play: No parameter setting is required, and it can be put into use immediately after installation

VI. Common faults and solutions

Fault phenomenon Possible causes Solutions

The material belt cannot be advanced 1. The ratchet is worn

2. The material belt is stuck

3. The drive mechanism is faulty 1. Replace the ratchet assembly

2. Clean the material belt path

3. Check the drive head of the placement machine

Inaccurate feeding step 1. Ratchet spring fatigue

2. Uneven material belt tension 1. Replace the reset spring

2. Adjust the tension of the tray

The material belt deviates 1. Improper guide groove adjustment

2. Guide rail is worn 1. Readjust the guide groove

2. Replace the guide rail

Abnormal noise 1. Insufficient lubrication

2. Bearing damage 1. Add grease

2. Replace the bearing

The material belt is easy to fall off 1. The pressure plate is deformed

2. The fixing screw is loose 1. Correct the pressure plate

2. Tighten all screws

VII. Maintenance Guide

1. Daily maintenance

Cleaning and maintenance:

Use an air gun to remove debris inside the feeder every day

Wipe the surface of the guide rail with non-woven cloth every week

Lubrication and maintenance:

Apply special grease to the moving parts every month (Kluber Isoflex Topas L32 is recommended)

2. Regular maintenance (every 6 months)

Comprehensive inspection:

Check the wear of the ratchet (wear > 0.1mm needs to be replaced)

Test the spring force

Deep cleaning:

Disassemble and clean all moving parts

Accuracy verification:

Use a standard tape to test the feeding accuracy (the error should be ≤ ±0.1mm)

VIII. Precautions for use

Tape loading:

Ensure that the tape enters the guide groove straight

Avoid twisting or folding of the tape

Environmental requirements:

Working temperature 10-40℃

Relative humidity 30-75%RH

Operation specification:

Release the material belt pressure plate completely when changing materials

Do not push the material belt manually

IX. Selection suggestions

Applicable scenarios:

Mass production of standard size components

Cost-sensitive production environment

Spare feeder requirements

Not applicable scenarios:

Precision placement requiring lack of material detection

Non-standard spacing material belt

X. Summary

Siemens 16mm feeder 00141372 without sensor is an ideal choice for medium and large component placement with its excellent reliability, extremely low maintenance requirements and super high cost performance. Although the function is relatively simple, its solid structural design and long life characteristics make it perform well in specific applications. Recommended users:

Regularly check the mechanical wear

Maintain proper lubrication

Through reasonable use and maintenance, the equipment can ensure many years of stable service and effectively reduce production costs.