1. Dulmarka alaabta iyo Faa'iidooyinka Muhiimka ah

1.1 Meelaynta Alaabta

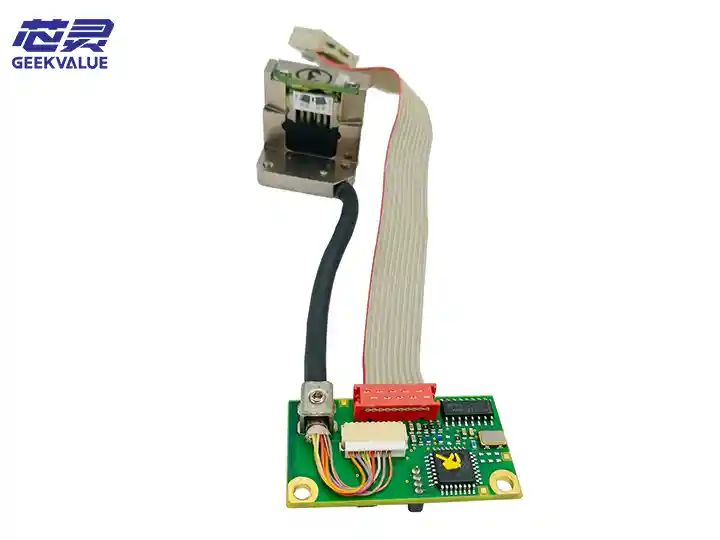

Siemens 3 × 8 SL Feeder (Model: 00141088) waa aalad quudin saddex-channel ah oo isku mid ah oo loogu talagalay in si hufan loogu habeeyo cajaladaha 8mm. Waxay isla mar ahaantaa quudin kartaa saddex qaybood oo kala duwan, si weyn u hagaajinaysa hufnaanta meelaynta iyo dabacsanaanta khadadka wax soo saarka SMT.

1.2 Faa'iidooyinka asaasiga ah

Naqshad hufan oo saddex-in-mid ah: hal quudiye wuxuu xaqiiqsadaa sahayda isku-dhafka ah ee saddex qaybood, badbaadinta booska saldhigga

Maareynta kanaalka caqliga leh: xakamaynta madaxbannaan ee ficil quudinta kanaal kasta

Waafaqid aadka u sarreeya: ku habboon SIPLACE mashiinnada meelaynta oo dhan

Quudinta saxda ah: saxnaanta tallaabada ± 0.04mm (@23± 1℃)

Beddel sheyga degdega ah: nashqada furitaanka patent-ka, wakhtiga beddelka alaabta <8 ilbiriqsi

Qaab dhismeedka nolosha dheer: nolosha qaybta muhiimka ah ≥10 milyan jeer

II. Tilmaamaha farsamada iyo sifooyinka qaabdhismeedka

2.1 Halbeegyada aasaasiga ah

Qiimaha Halbeegga Shayga

Balaadhka cajaladda 3×8mm (madax banaan kanaalkiiba)

Talabada quudinta 2/4/8mm (barnaamij la samayn karo)

Dhererka qaybta ugu badan 3mm (kanaalkiiba)

Dhumucdiisuna waxay u dhaxaysaa 0.1-0.5mm

Xawaaraha quudinta 45 jeer/daqiiqo (ugu badnaan)

Koronto sahayda 24VDC±5%

Interface isgaarsiinta RS-485

Heerka ilaalinta IP54

Miisaanka 1.2kg

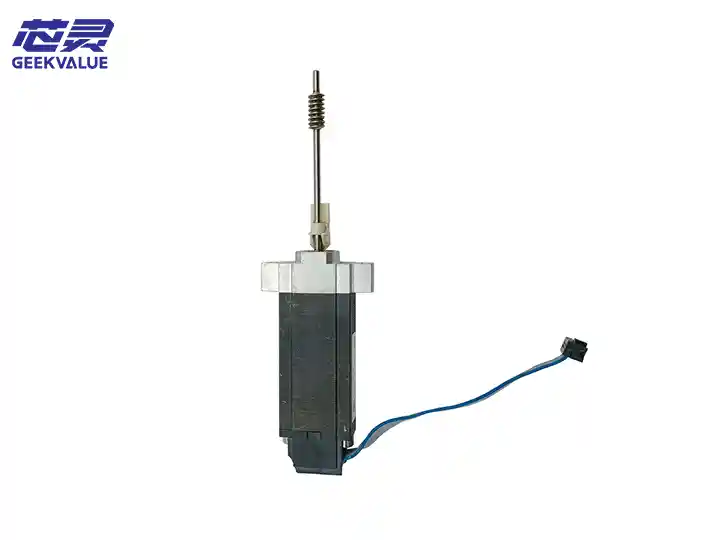

2.2 Qaabdhismeedka makaanikada

Nidaamka madaxbannaan ee saddex-kanaal:

Matoor madax bannaan

Habka quudinta qaab-dhismeedka (waxaa loo bedeli karaa si gaar ah)

Habka hagaha:

Xadiidka hagaha dhoobada saxda ah (HV1500 adag)

Qalabka riixaya ee qaybsan (3 dhibcood cadaadis kanaalka)

Habka dareemayaasha:

Dareemaha hoolka ayaa ogaanaya booska quudinta

Dareemaha indhaha ayaa isha ku haya heerka suunka walxaha (ikhtiyaar)

Naqshad isbeddel degdeg ah:

Hawlgalka gacanta kaliya ee habka sii deynta suunka walxaha

Kanaalka midabo leh (cas/buluug/cagaar)

III. Hawlaha muhiimka ah iyo qiimaha khadka wax soo saarka

3.1 Hawlaha caqliga

kanaalka madaxa banaan:

Dejinta barnaamijka quudinta masaafada tallaabo ee kanaal kasta

Taageer quudinta isku dhafan ee qaybaha kala duwan

La socodka xaalada:

suunka alaabta ka hadhay ogaanshaha cadadka

Quudinta digniin aan caadi ahayn

Tirakoobka isticmaalka kanaalka

Maamulka xogta:

Kaydinta quudinta kanaal kasta

Diiwaangeli 50-kii macluumaadka digniinta ugu dambeeyay

3.2 Qiimaha khadka wax soo saarka

Badbaadinta booska: Iska yaree baahida 2 saldhig

Horumarinta hufnaanta: Iska yaree inta jeer ee isbeddelka walxaha 67%

Kordhinta qiimaha: Yaree maalgashiga qalabka 40%

Wax soo saarka dabacsan: Jawaab degdeg ah oo ku saabsan beddelka alaabta

IV. Xaaladaha codsiga

4.1 Qaybaha codsiga caadiga ah

Isku dhafka / capacitor

Isku darka transistor

Qaybta RGB LED

Koox yar oo isku xidha

module Sensor

4.2 Warshadaha lagu dabaqi karo

Elektrooniga macaamiisha

Qaybta kontoroolka baabuurta

Qalabka Internetka ee Waxyaabaha

Elektrooniga caafimaadka

module gacanta warshadaha

V. Khaladaadka iyo xalalka caadiga ah

5.1 Miiska tixraaca degdega ah ee koodhka qaladka

Sharaxaada Cilada koodka Sababta suurtogalka ah ee xal xirfadeed

E301 Channel 1 quudinta oo fashilantay 1. Cajalad wax ku dhegtay

2. Baabuurka oo xumaada 1. Hubi dariiqa cajaladda alaabta

2. Tijaabi dabaylaha mootada (waa inay noqotaa 8±0.5Ω)

E302 Channel 2 dareenka aan caadiga ahayn 1. Wasakhda

2. Xiriir xumo 1. Nadiifi daaqadda dareemayaasha

2. Hubi xiriiriyaha FPC

E303 Isgaadhsiinta Go'a 1. Burburka fiilada

2. Iska caabbinta Terminal 1. Hubi khadka RS-485

2. Xaqiiji iska caabbinta 120Ω

E304 Channel 3 weecsanaanta booska 1. Qaladka Parameter

2. Gear xirashada 1. Dib u habeyn

2. Hubi nadiifinta meshing gear

E305 Multi-channel khilaafka 1. Qaladka barnaamijka

2. Faragelinta ishaarada 1. Hubi wakhtiga quudinta

2. Ku dar tallaabooyinka gaashaanka

5.2 Baadhitaannada gaarka ah ee kanaalka

Tijaabada go'doominta kanaalka:

Kaall walba si gaar ah ugu dhaqaaji HMI

U fiirso in ficilka quudinta uu yahay mid siman

Falanqaynta qaabka hirarka hadda:

Qiyaasta caadiga ah ee hadda jirta: 0.6-1.2A

Qaabka mowjadaha aan caadiga ahayn ayaa tilmaamaya iska caabin farsamo

Kormeerka indhaha:

Isticmaal muraayada weynaynta si aad u ilaaliso xidhashada tareenka

Hubi dhaawaca godadka iliga suunka

VI. Tilmaamaha Dayactirka

6.1 Dayactirka maalinlaha ah

Nadiifinta:

Ku masax dusha quudiyaha maro aan boodh lahayn maalin kasta

Ku nadiifi qashinka hagaha qashinka hagaha qoriga hawada toddobaad kasta (cadaadiska ≤ 0.15MPa)

Maareynta Saliida:

Saliid Bishiiba:

Hagaha tareenka: Kluber ISOFLEX NBU15 (0.1g/channel)

Gear: Molykote EM-30L (hab daahan burush)

Goobaha Kormeerka:

Xaqiiji xoogga cadaadiska kanaalka maalin kasta

Hubi heerka xidhiidhiyaha toddobaad kasta

6.2 Dayactirka Qoto dheer ee Joogtada ah

Samee saddexdii biloodba mar:

Kala furfur oo nadiifi habka quudinta kanaalka kasta

Kala beddel isbarbardhigga kanaalka (qalab gaar ah ayaa loo baahan yahay)

Tijaabi wakhtiga jawaabta dareemaha (waa inay noqotaa <5ms)

Beddel baadiyaha duugoobay (ugu badnaan la oggol yahay 0.02mm)

Dayactirka Sannadlaha ah:

Si buuxda u beddel qaybaha xiran:

Qalabka quudinta

guga cadaadiska

Ogaanshaha dahaarka nidaamka korantada

Casriyeynta Firmware iyo hagaajinta cabbirka

VII. Cilladaha caadiga ah iyo fikradaha dayactirka

7.1 Falanqaynta qaladka caadiga ah

Asynchrony-ka-badan:

Hubi calaamada saacada looxa kantaroolka ugu weyn

Hubi socodka waditaanka mootada kanaalka kasta

Cilad kali ah oo kanaalka ah:

Cabbir danabka sahayda kanaalka (waa inuu ahaado 24 ± 0.5V)

Hubi heerka sawir-qaade

Meelaynta cajaladda oo aan sax ahayn:

Hagaaji isbarbardhigga tareenka hagaha

Beddel jiirkii duugoobay

7.2 shaxda socodka dayactirka

qoraal

Bilow → Xaqiijinta ifafaale → Tijaabada go'doominta kanaalka → Ogaanshaha koronto → Kormeerka makaanikada

↓ ↓ ↓ ↓

Baaritaanka HMI → Beddel guddiga kantaroolka → Hagaajinta wareegga wadista → Beddel qaybaha farsamada

↓

Qiyaasta cabbirka → Imtixaan hawleed → Dhammaad

VIII. Kobcinta tignoolajiyada iyo talooyinka cusboonaysiinta

8.1 Nooca ku celcelinta

2015 jiilka kowaad: quudiyaha saddex-channel aasaasiga ah

2017 jiilka labaad: Hagaajinta nidaamka tareenada hagaha

Jiilka saddexaad ee 2019: nooca caqliga hadda jira

2022 jiilka afraad (qorshaysan): kormeer muuqaal ah oo isku dhafan

8.2 Jidka hagaajinta

Casriyeynta qalabka:

Codeeye sax ah oo sarreeya oo ikhtiyaari ah

U cusboonaysii xidhiidhka baska CAN

cusboonaysiinta software:

Ku rakib Advanced Channel Management Suite

Daree shaqada dayactirka saadaalinta

Isdhexgalka nidaamka:

Isku xidhka nidaamka MES

La socodka fog

IX. Falanqaynta isbarbardhigga tartamayaasha

Waxyaalaha isbarbardhigga 3×8 SL Feeder Tartamiyaha B

Madaxbanaanida kanaalka Isku xidhka madax-banaani buuxda oo dhamaystiran

Saxnaanta quudinta ± 0.04mm ± 0.06mm ± 0.1mm

Waqtiga beddelka <8 sekan 12 sekan 15 sekan

Interface isgaarsiinta RS-485 CAN RS-232

Qiimaha wareegga nolosha $0.002/wakhti $0.003/wakhti $0.005/wakhti

X. Soo jeedinta isticmaalka iyo kooban

10.1 Hababka ugu fiican

Hagaajinta cabbirka:

Samee jaangooyooyin cabirka kanaalka ee qaybaha kala duwan

Daar "Feed jilicsan" shaqada waxay ilaalisaa qaybaha saxda ah

Xakamaynta deegaanka:

Ku ilaali heerkulka 20-26 ℃

Xakamaynta qoyaanka 30-70% RH

Istaraatiijiyada agabka agabka:

Qaybaha muhiimka ah ee heeganka ah:

Dejinta qalabka kanaalka (P/N: 00141089)

Qalabka dareemayaasha (P/N: 00141090)

10.2 Kooban

Siemens 3 × 8 SL Feeder 00141088 waxay noqotay doorasho ku habboon wax soo saarka cufnaanta sare ee SMT oo leh naqshadeeda cusub ee saddexda kanaal, ka faa'iidaysiga meel wanaagsan iyo waxqabadka quudinta saxda ah. Astaamaha uu leeyahay waxaa ka mid ah:

Kacaanka waxtarka leh: hal quudiye wuxuu gaaraa saddex jeer awoodda quudinta

Xakamaynta caqliga leh: kanaal kasta si madaxbanaan u maamul

Lagu kalsoonaan karo oo waara: qaab-dhismeedka farsamada ee darajada milatariga

Jihada horumarka mustaqbalka:

Algorithm hagaajinta kanaalka AI ee isku dhafan

Isticmaal walxaha isku dhafan ee is-saliimaynta ah

Gaadhi qaabaynta xuddunta wireless-ka

Ku talin isticmaalayaasha:

Samee habka wareegga isticmaalka kanaalka

Si joogto ah u samee xaqiijinta saxda ah ee farsamada

Tababar kooxda dayactirka xirfadlayaasha ah

Qalabku wuxuu si gaar ah ugu habboon yahay:

Soo saarista Motherboard-ka casriga ah

Module kantaroolka baabuurta

Isku-xidhka elegtarooniga ah ee cufnaanta sare leh

Wax soo saarka dufcad yar oo kala duwan

Iyada oo loo marayo isticmaalka sayniska iyo dayactirka xirfadlaha ah, quudiyaha 3 × 8 SL wuxuu hubin karaa hawlgal xasilloon oo muddada dheer ah wuxuuna bixiyaa xal quudin qaybo badan oo la isku halleyn karo oo wax soo saarka SMT oo hufan.