1. Isishwankathelo seMveliso kunye nezinto eziluncedo ezingundoqo

1.1 Ukuma kweMveliso

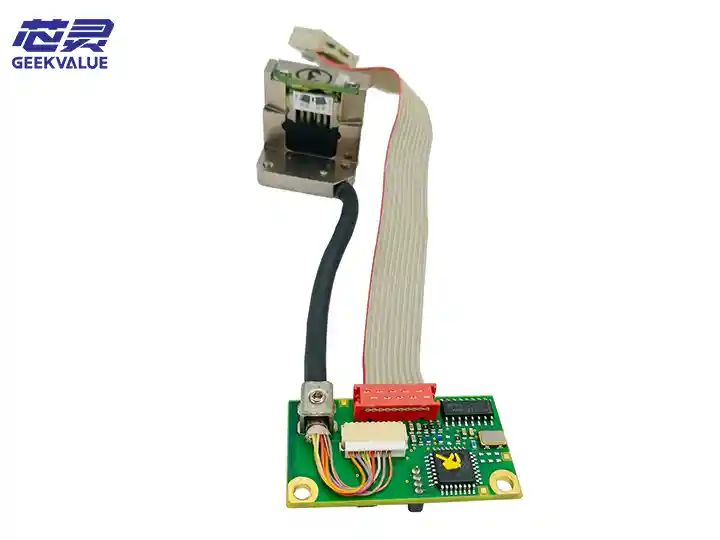

I-Siemens 3 × 8 SL Feeder (Imodeli: 00141088) sisixhobo sokutyisa esine-synchronous esineendlela ezintathu esenzelwe ukusetyenzwa ngokufanelekileyo kweeteyiphu ze-8mm. Inokondla ngaxeshanye amacandelo amathathu ahlukeneyo, ukuphucula ngokubonakalayo ukusebenza kakuhle kokubekwa kunye nokuguquguquka kwemigca yokuvelisa i-SMT.

1.2 Iinzuzo eziphambili

Uyilo olusebenzayo lwesithathu-kwinye: Isondlo esinye siqonda unikezelo oluhambelanayo lwamacandelo amathathu, ukugcina indawo yesikhululo

Ulawulo lwejelo olukrelekrele: ulawulo oluzimeleyo lwesenzo sokutyisa sejelo ngalinye

Ukuhambelana okuphezulu kakhulu: iyahambelana ne-SIPLACE uluhlu olupheleleyo lweematshini zokubeka

Ukutya okuchanekileyo: ukuchaneka kwenyathelo ±0.04mm (@23±1℃)

Ukutshintsha kwezinto ezikhawulezayo: uyilo lokuvula i-patent, ixesha lokutshintsha izinto <8 imizuzwana

Isakhiwo sobomi obude: ubomi becandelo eliphambili ≥10 amaxesha ezigidi

II. Iinkcukacha zobugcisa kunye neempawu zesakhiwo

2.1 Iiparamitha ezisisiseko

Ixabiso leParameter yento

Tape ububanzi 3×8mm (izimele ngetshaneli)

Inyathelo lokutyisa 2/4/8mm (iyacwangciswa)

Obona bude bubude buyi-3mm (kwitshaneli nganye)

Tape ubukhulu ububanzi 0.1-0.5mm

Isantya sokutya ngamaxesha angama-45/umzuzu (ubuninzi)

Umbane wombane 24VDC±5%

Unxibelelwano lonxibelelwano RS-485

Inqanaba lokhuseleko IP54

Ubunzima 1.2kg

2.2 Iimpawu zesakhiwo soomatshini

Inkqubo ezimeleyo enamajelo amathathu:

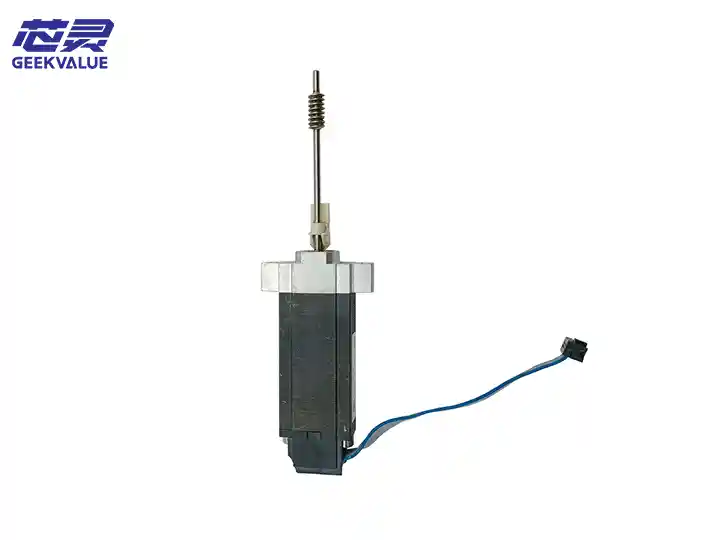

Ukuqhuba kwemoto ye-stepper ezimeleyo (0.9° inyathelo leengile kwitshaneli nganye)

Indlela yokondla ngokwemodyuli (inokutshintshwa ngokwahlukileyo)

Indlela yokukhokela:

Uloliwe ochanekileyo we-ceramic guide (ubunzima HV1500)

Isixhobo sokucinezela esicandiweyo (iindawo ezi-3 zoxinzelelo kwitshaneli nganye)

Inkqubo yoluvo:

Inzwa yeholo ibona indawo yokondla

Isivamvo sokubonwa sijonga ubume bebhanti (ukhetho)

Uyilo olukhawulezayo lokutshintsha:

Ukusebenza kwesandla esinye somatshini wokukhulula ibhanti

Ijelo elinekhowudi yombala (bomvu/blowu/luhlaza)

III. Imisebenzi engundoqo kunye nexabiso lomgca wemveliso

3.1 Imisebenzi yobukrelekrele

Ulawulo lwesitishi esizimeleyo:

Ukusetwa okucwangcisiweyo komgama wokutya kwitshaneli nganye

Xhasa ukutyisa okuxutyiweyo kwamacandelo ahlukeneyo

Ukujongwa kwemeko:

Ibhanti yezinto ezishiyekileyo zokubona imali

Ukutya isilumkiso esingaqhelekanga

Amanani okusetyenziswa kwejelo

Ulawulo lwedatha:

Gcina amanani okutyisa kwitshaneli ngalinye

Rekhoda ulwazi lwamva nje lwe-alam engama-50

3.2 Ixabiso lomgca wemveliso

Ugcino lwesithuba: Nciphisa imfuno yezikhululo ezi-2 zokutya

Uphuculo olusebenzayo: Nciphisa utshintsho lwezinto eziphathekayo ngama-67%

Ukulungiswa kweendleko: Nciphisa utyalo-mali lwezixhobo ngama-40%

Imveliso eguquguqukayo: Ukuphendula ngokukhawuleza ekutshintsheni imveliso

IV. Iimeko zesicelo

4.1 Amacandelo osetyenziso oluqhelekileyo

Uluhlu lwe-resistor / capacitor

Umdibaniso weTransistor

Icandelo le-RGB ye-LED

Iqela elincinane lokudibanisa

Imodyuli yoluvo

4.2 Amashishini asebenzayo

Ii-elektroniki zabathengi

Iyunithi yolawulo lweemoto zombane

Isixhobo se-Intanethi yezinto

Medical electronic

Imodyuli yolawulo lweshishini

V. Iimpazamo eziqhelekileyo kunye nezisombululo

5.1 Itheyibhile yereferensi ekhawulezayo yekhowudi

Ikhowudi Inkcazo yempazamo enokwenzeka Isisombululo sobuchwephesha

E301 Channel 1 ukondla ukusilela 1. Material tape waxinga

2. Ukungaphumeleli kweemoto 1. Khangela indlela yeteyiphu yezinto

2. Vavanya ukujika kwemoto (kufuneka ibe yi-8±0.5Ω)

E302 Ijelo le-2 yesivamvo esingaqhelekanga 1. Ungcoliseko

2. Uxhulumaniso olubi 1. Coca ifestile yoluvo

2. Jonga isidibanisi seFPC

E303 Uphazamiseko lonxibelelwano 1. Ukonakala kwentambo

2. Ukuxhathisa i-terminal 1. Khangela umgca we-RS-485

2. Qinisekisa i-120Ω uxhathiso lwesiphelo

I-E304 Isiteshi se-3 sokutenxa 1. Impazamo yeParameter

2. Ukunxitywa kwezixhobo 1. Hlaziya kwakhona

2. Qwalasela ukucoceka kwe-gear meshing

E305 Ungquzulwano lwamajelo amaninzi 1. Impazamo yenkqubo

2. Ukuphazamiseka komqondiso 1. Qwalasela ixesha lokutyisa

2. Yongeza amanyathelo okukhusela

5.2 I-Channel-specific diagnostics

Uvavanyo lokwahlulwa kwejelo:

Vula ijelo ngalinye nge-HMI

Jonga ukuba isenzo sokutyisa sigudile na

Uhlalutyo lwangoku lwamaza:

Uluhlu lwangoku oluqhelekileyo: 0.6-1.2A

I-waveform engaqhelekanga ibonisa ukuxhathisa koomatshini

Ukuhlolwa kwamehlo:

Sebenzisa iglasi yokukhulisa ujonge ukunxiba kukaloliwe

Jonga umonakalo wemingxuma yamazinyo ebhanti

VI. Iinkcukacha zoLondolozo

6.1 ULondolozo lweMihla le

Ukucoca:

Sula umphezulu we-feeder ngelaphu elingenathuli yonke imihla

Coca inkunkuma yesikhokelo ngompu womoya rhoqo ngeveki (uxinzelelo ≤ 0.15MPa)

Ulawulo lokuthambisa:

Ukuthanjiswa kweNyanga:

Umzila kaloliwe: Kluber ISOFLEX NBU15 (0.1g/channel)

Isixhobo: Molykote EM-30L (indlela yokwaleka ibrashi)

Iindawo zokuHlola:

Qinisekisa amandla oxinzelelo lwejelo ngalinye yonke imihla

Jonga ubume besinxibelelanisi qho ngeveki

6.2 ULondolozo oluNzulu rhoqo

Yenza ngeKota:

Hlukanisa kwaye ucoce indlela yokutya yomjelo ngamnye

Lungiselela ukuhambelana kwetshaneli (umdlalo okhethekileyo uyafuneka)

Vavanya ixesha lokuphendula loluvo (kufuneka libe <5ms)

Buyisela i-bushing egugileyo (ubona bukhulu bemvume obuvumelekileyo yi-0.02mm)

ULondolozo loNyaka:

Zibuyisele ngokupheleleyo iindawo ezigugileyo:

Iseti yezixhobo zokutya

Intwasahlobo yoxinzelelo

Ukubona ukugqunywa kwenkqubo yombane

Uphuculo lweFirmware kunye nokwenza ngcono iparameter

VII. Iimpazamo eziqhelekileyo kunye neengcamango zokulondoloza

7.1 Uhlalutyo lwemposiso eqhelekileyo

Iasynchrony yamajelo amaninzi:

Jonga isignali yewotshi yebhodi engundoqo

Qinisekisa i-motor drive yangoku yetshaneli nganye

Ukusilela kwesitishi esinye:

Ukulinganisa amandla ombane wetshaneli (kufuneka ibe yi-24±0.5V)

Jonga imo ye-photocoupler

Indawo yeteyiphu engafanelekanga:

Lungisa ukuhambelana kwesikhokelo sikaloliwe

Buyisela iratchet egugileyo

7.2 Itshati equkuqelayo yogcino

umbhalo

Qala → uqinisekiso lwesenzeko → uvavanyo lokwahlulwa kwejelo → Ubhaqo loMbane → Ukuhlolwa koomatshini

↓ ↓ ↓ ↓

Ukuxilongwa kwe-HMI → Buyisela ibhodi yolawulo → Lungisa isekethe yokuqhuba → Buyisela amalungu oomatshini

↓

Ulungelelwaniso lweparamitha → Uvavanyo olusebenzayo → Phelisa

VIII. Ukuvela kweTekhnoloji kunye neengcebiso zokuphucula

8.1 Uphindaphindo lwenguqulelo

Isizukulwana sokuqala sika-2015: isiseko se-channel three feeder

Isizukulwana sesibini sika-2017: Ukuphucula indlela kaloliwe yesikhokelo

Isizukulwana sesithathu sika-2019: inguqulelo ekrelekrele yangoku

I-2022 isizukulwana sesine (esicwangcisiweyo): ukuhlolwa okubonakalayo okudibeneyo

8.2 Ukuphucula indlela

Uphuculo lweHardware:

Ukhetho lwe-encoder oluchanekileyo oluphezulu

Nyukela kunxibelelwano lwebhasi ye-CAN

Uphuculo lwesoftware:

Faka i-Advanced Channel Management Suite

Yenza umsebenzi wogcino oluqikelelweyo

Udibaniso lwenkqubo:

Uqhagamshelwano lwenkqubo ye-MES

Ukubeka iliso kude

IX. Uhlalutyo lokuthelekisa kunye nabakhuphisana nabo

Izinto zokuthelekisa 3×8 SL Ukhuphisana noMkhuphisani B

Ukuzimela kweSitishi Ngokupheleleyo ezizimeleyo eziSemi-ezizimeleyo Unxulumano

Ukuchaneka kokutya ±0.04mm ±0.06mm ±0.1mm

Ixesha lokutshintsha <8 imizuzwana 12 imizuzwana 15 imizuzwana

Unxibelelwano lonxibelelwano RS-485 CAN RS-232

Umjikelo wobomi ubiza i-$ 0.002 / ixesha $ 0.003 / ixesha $ 0.005 / ixesha

X. Iingcebiso zosetyenziso kunye nesishwankathelo

10.1 Iinkqubo ezigqwesileyo

Ukulungiselela iParameter:

Ukuseka iitemplates zeparameter yetshaneli kumacandelo ahlukeneyo

Yenza "ukutya okuthambileyo" umsebenzi ukhusela amacandelo achanekileyo

Ulawulo lokusingqongileyo:

Gcina ubushushu kwi-20-26 ℃

Lawula ukufuma kwi-30-70% RH

Isicwangciso sezixhobo ezisecaleni:

Amacandelo angundoqo alindileyo:

Iseti yesixhobo somjelo (P/N: 00141089)

Imodyuli yoluvo (P/N: 00141090)

10.2 Isishwankathelo

I-Siemens 3 × 8 SL Feeder 00141088 ibe lolona khetho lufanelekileyo kwimveliso ye-SMT enoxinaniso oluphezulu kunye noyilo oluyilayo lwetshaneli ezintathu, ukusetyenziswa kwendawo egqwesileyo kunye nokusebenza okuchanekileyo kokutyisa. Iimpawu zayo ezibalaseleyo ziquka:

Uguqulo lobuchule: umxhesho omnye ufezekisa umthamo wokutya okuphindwe kathathu

Ulawulo oluhlakaniphile: lawula ijelo ngalinye ngokuzimeleyo

Ithembekile kwaye ihlala ixesha elide: ulwakhiwo lomatshini womgangatho womkhosi

Umkhombandlela wophuhliso lwexesha elizayo:

I-algorithm yokuphucula itshaneli ye-AI

Sebenzisa i-self-lubricating composite materials

Phumelela uqwalaselo lweparamitha engenazingcingo

Cebisa abasebenzisi:

Ukuseka inkqubo yokujikeleza yokusetyenziswa kwejelo

Yenza ungqinisiso oluchanekileyo ngoomatshini rhoqo

Qeqesha iqela logcino lobungcali

Isixhobo sifanelekile ngokukodwa:

Imveliso ye-motherboard ye-smartphone

Imodyuli yolawulo lwe-elektroniki yeemoto

Indibano ye-elektroniki yoxinaniso oluphezulu

Iintlobo ezininzi zeebhetshi ezincinci zemveliso

Ngokusetyenziswa kwezenzululwazi kunye nokugcinwa kobugcisa, i-3 × 8 SL feeder inokuqinisekisa ukusebenza okuzinzile kwexesha elide kunye nokubonelela ngesisombululo esithembekileyo sokutya esinezixhobo ezininzi zokuvelisa i-SMT esebenzayo.