Siemens SIPLACE X4 (SX4 for short) is a high-speed modular placement machine launched by Siemens Electronic Assembly Systems (now under ASM Assembly Systems). It features high precision, high flexibility and high productivity, and is suitable for mid-to-high-end electronic manufacturing fields such as communications, automotive electronics, medical equipment, etc.

2. Core advantages

High speed and high precision

The theoretical placement speed can reach >100,000 CPH (depending on the configuration).

Repeat accuracy reaches ±25μm @3σ, supporting micro components such as 01005 and 0.3mm pitch QFN.

Modular design

Multi-arm and multi-placement heads can be flexibly configured to support mixed production of special-shaped components and high-speed placement.

Intelligent calibration system

Equipped with On-the-fly Vision, real-time position correction during placement reduces downtime.

Strong compatibility

Supports a variety of components from 0201 to large connectors, shielding covers, etc., and can expand the wafer (Die Bonder) function.

Digital integration

Supports ASM OMS (optimization management software) and Industry 4.0 interface to achieve production data traceability and analysis.

III. Key features

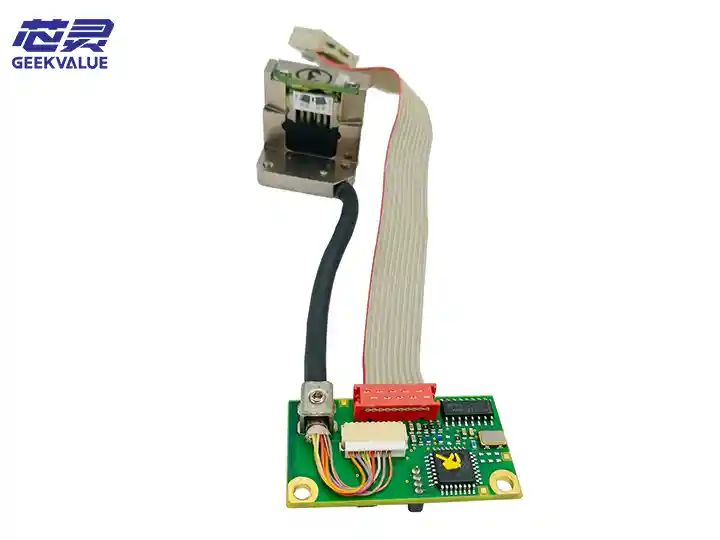

Placement head technology

Optional rotary placement head (such as SpeedStar head) or high-precision head to meet different component requirements.

Feeding system

Supports dual lane feeder (Dual Lane Feeder), material change without stopping the machine, improving efficiency.

Vision system

High-resolution camera (such as 12MP) combined with multi-spectral lighting, accurately identifies complex components (such as BGA, PoP).

Adaptive placement

Pressure control technology (Z-axis force control) to avoid component damage or cold soldering.

4. Main Specifications

Item Parameters

Placement speed Up to 100,000+ CPH (depending on configuration)

Placement accuracy ±25μm @3σ

Component range 01005 ~ 150mm × 150mm

Number of feeders Support up to 200+ (8mm tape)

Substrate size 50mm × 50mm ~ 510mm × 460mm

Software platform SIPLACE Pro/ASM OMS

5. Common faults and maintenance ideas

1. Placement offset

Possible causes:

Visual calibration deviation;

Nozzle wear or contamination;

Component parameter setting error (such as thickness, size).

Solution steps:

Clean the camera lens and nozzle;

Recalibrate the visual system (using a standard calibration board);

Check the component library parameters and update the placement coordinates.

2. High throw rate

Possible causes:

Insufficient vacuum at the nozzle (blockage or leakage);

Abnormal stepping of the feeder;

Failed component recognition (illumination or focus problem).

Solution steps:

Check vacuum line and filter;

Clean or replace nozzle;

Adjust feeder gear position;

Optimize visual lighting parameters.

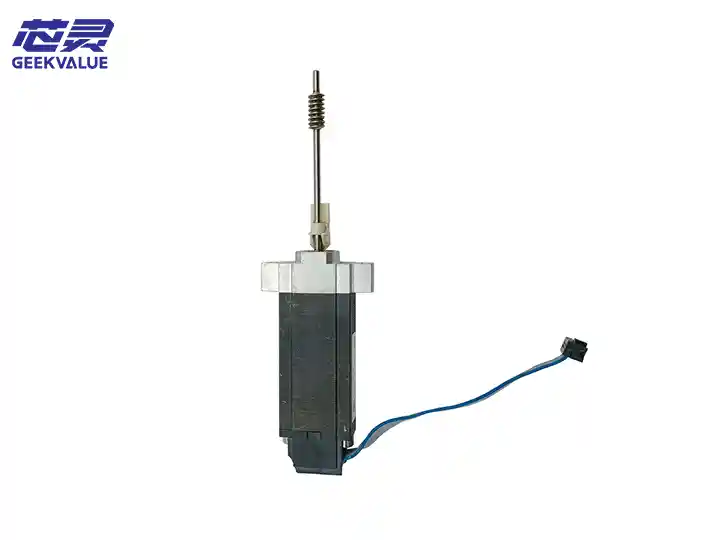

3. Machine alarm (servo drive failure)

Possible causes:

Motor overload or encoder failure;

Power fluctuation;

Mechanical jamming.

Solution steps:

Restart the system and observe the alarm code (such as E-stop or Axis Error);

Check the lubrication of the guide rail and lead screw;

Measure the servo drive voltage.

4. The feeder does not feed

Possible causes:

The tape is stuck or the reel tension is abnormal;

The sensor is dirty;

Poor electrical connection.

Solution steps:

Pull the tape manually to remove the jam;

Clean the feeder sensor;

Replug the signal line.

VI. Maintenance Recommendations

Daily maintenance:

Clean the nozzle and camera lens daily;

Regularly lubricate the linear guide and lead screw.

Periodic calibration:

Perform visual system and placement head precision calibration every month.

Spare parts management:

Standard wearing parts: nozzle, vacuum filter, feeder accessories.

VII. Summary

Siemens SX4 is suitable for high-mix, high-volume production environments with its modular design, high-precision placement and intelligent management. During maintenance, it is necessary to focus on preventive maintenance and quickly locate problems in combination with fault codes and system logs. For complex faults (such as servo system problems), it is recommended to contact ASM official technical support or authorized service providers.

If you need a more specific operating manual or fault code interpretation, you can refer to the SIPLACE X4 Service Manual or get support through ASM's remote diagnostic tool.