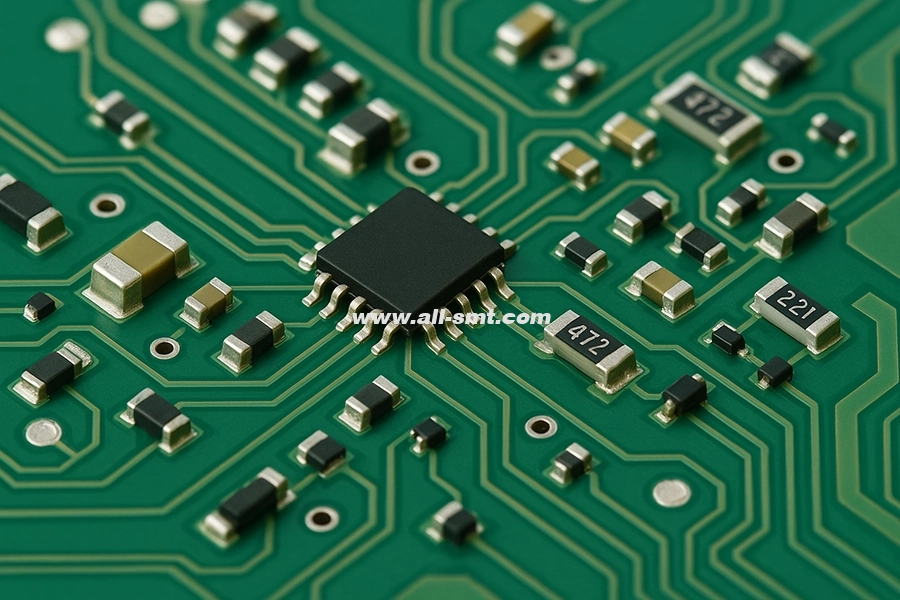

AIsiXhobo sokuMount-phezulu (SMD)licandelo lombane elenzelwe ukuba lixhonywe ngqo kumphezulu webhodi yesekethe eprintiweyo (PCB). Ngokungafaniyo nezinto zemveli zokutyhutyha ezifuna imingxuma egrunjiweyo, ii-SMDs zibekwe kwaye zithengiswe kwiipads zobhedu ezisicaba. Le ndlela igcina indawo, inciphisa ubunzima, kwaye ivumela ukwakheka kweesekethe eziphezulu. Itekhnoloji ye-SMD yaba sisiseko se-elektroniki yanamhlanje kuba ivumela ukusebenzisana okuzenzekelayooomatshini bokukhetha kunye nendawo, ebeka amawaka eenxalenye ngesantya kunye nokuchaneka. Ii-SMD eziqhelekileyo ziquka i-resistors, i-capacitors, i-diodes, i-transistors, kunye neesekethe ezidibeneyo, zonke ezikhoyo kwizixhobo zemihla ngemihla ezifana nee-smartphones, ii-laptops, kunye nezixhobo zonyango.

Ukuqonda iTekhnoloji ye-SMD

Inkcazelo yesiXhobo soMphezulu weMount (SMD)

AnSMDlicandelo elincinci elenzelweitekhnoloji yokunyuka komphezulu (SMT). Ezi zixhobo ziza ngaphandle kokhokelo olude; endaweni yoko, basebenzisa abafowunelwa besinyithi abafutshane abaphumla ngokuthe ngqo kwi-solder pads. Ubungakanani babo obubambeneyo buvumela iinjineli ukuba zilingane iisekethe ezininzi kwiiPCB ezincinci, eziyimfuneko kwii-elektroniki zanamhlanje eziphathwayo.

Umahluko phakathi kwe-SMD kunye neTekhnoloji ye-Hole-Hole

Amacandelo ngokusebenzisa-umngxuma kufuna imingxuma ukugrumba kwi-PCB, edla indawo kunye nemida uyilo bhetyebhetye. Amacandelo e-SMD, ngokuchaseneyo, afakwe ngokuthe ngqo kumphezulu. Olu tshintsho lunyusa kakhulu ukuxinana kwecandelo kwaye lunciphisa iindleko zokuvelisa. Ngokomzekelo, i-smartphone enezigidi ze-transistors ingaba khona kuphela ngenxa yeenkqubo ze-SMD kunye ne-SMT.

Kutheni i-SMD yaba nguMgangatho woShishino

I-teknoloji ye-SMD yafumana ukuthandwa kwi-1980, xa abavelisi bafuna iindlela zokunciphisa iimveliso ngelixa bephucula ukusebenza. Ukudityaniswa okuzenzekelayo kusetyenziswa oomatshini bokukhetha kunye nendawo benza imveliso yobuninzi be-SMD ingabizi kakhulu. Namhlanje, ngaphezu kwe-90% yeendibano ze-elektroniki kwihlabathi jikelele zixhomekeke kwi-SMT, okwenza amacandelo e-SMD abe ngumgangatho wehlabathi.

Imbali kunye ne-Evolution ye-SMD

Iintsuku zokuqala zeNdibano yePCB

Ngaphambi kwe-SMD, iindibano ze-elektroniki zazininzi kwaye zingasebenzi kakuhle. Iinjineli zasebenzisa itekhnoloji yomngxunya ukuze zikhusele amacandelo aneendlela ezide. Ngelixa zomelele ngoomatshini, ezi ndibano zinomlinganiselo wokuxinana koyilo kwaye zicuthe imveliso.

Utshintsho ukusuka kwi-On-Hole ukuya kwi-SMD ngeminyaka yoo-1980

Ukutshintshela kubathengi be-elektroniki kubangele imfuno yezixhobo ezincinci, ezikhaphukhaphu, kunye nezingabizi kakhulu. Oku kukhokelele ekwazisweni kweitekhnoloji yokunyuka komphezulu. Abavelisi baseJapan babephakathi kwabokuqala ukwamkela i-SMT, ngokukhawuleza babonisa izibonelelo zayo koomabonwakude, oonomathotholo, kunye neenkqubo zoshishino.

Uphuhliso lwangoku kwi-SMT

Imigca yemveliso ye-SMT yanamhlanje isebenzisa oomatshini bokuchola kunye nendawo abanesantya esiphezulu abakwaziyo ukubeka izinto ezingaphezulu kwe-100,000 ngeyure. NONEiinkqubo zombonoqinisekisa ukuchaneka kwanamalungu amancinci, ngelixa i-reflow soldering ibonelela ngokuhambelana, uqhagamshelwano oluphezulu. Indibaniselwano yamacandelo e-SMD kunye nendibano ezenzekelayo iyaqhubeka nokutyhala i-elektroniki ukuya kwi-miniaturization kunye nokusebenza kakuhle.

Iindidi zezahlulo ze-SMD

I-SMD Resistors

Izichasi ze-SMD zilawula ukuhamba kwangoku kwiisekethe. Ziphawulwe ngeekhowudi zamanani (umz., 103 = 10kΩ). Uyilo lwabo oludityanisiweyo luvumela ukubekwa lula kwiiPCB, ezixhasa zombini iinkqubo ze-analog kunye nedijithali.

SMD Capacitors

IiCapacitors zigcina kwaye zikhulule amandla. Kwifom ye-SMD, zibonakala njengeebhloko ezincinci ezixande, eziqhelekileyo zenziwe kwi-ceramic okanye tantalum. Bazinzisa amandla ombane kunye nengxolo yokucoca kwii-smartphones, iikhompyuter, kunye nombane.

IiDiode ze-SMD

Iidiode ze-SMD zilawula indlela yangoku. Zisetyenziswa ngokubanzi ukulungiswa, ukukhuselwa komqondiso, kunye nokukhutshwa kokukhanya (ii-LEDs). Ubungakanani babo obuncinci buvumela ukuhlanganiswa kwizixhobo ezidibeneyo ngaphandle kokuncama ukuthembeka.

SMD Transistors

Iitransistor zisebenza njengokutshintsha okanye iamplifiers. Kwifomathi ye-SMD, zenza ulawulo lwamandla kunye nokusetyenzwa komqondiso kwii-elektroniki eziphathekayo. Iiprosesa zanamhlanje zixhomekeke kwiibhiliyoni zezi transistors zincinci.

IiSekethe eziDityanisiweyo ze-SMD (ICs)

Iisekethe ezidityanisiweyo ziindibano ezintsonkothileyo ze-transistors, resistors, kunye ne-capacitors ngaphakathi kwephakheji enye. Ii-SMD ICs zenza ii-microcontrollers ezinokwenzeka, iiprosesa, kunye neememori zetshiphu eziqhuba itekhnoloji ephezulu.

Izixhobo ezikhethekileyo ze-SMD

Ezinye iindawo ezikhethekileyo ziquka i-inductors, iikristale zequartz, kunye nee-LED. Ngamnye udlala indima ekulawuleni amaza, ukugcinwa kwamandla, okanye umqondiso wokubonwayo. Iinguqulelo zabo ze-SMD ziphucula ukusebenza ngelixa zinciphisa iimfuno zendawo.

Iikhowudi zokupakisha ze-SMD kunye nobukhulu

Iikhowudi ze-SMD eziqhelekileyo

Amacandelo e-SMD achongwa ngobungakanani bephakheji, njenge0402, 0603, 0805, kunye ne-1206. Amanani amele ubude kunye nobubanzi kwikhulu le-intshi. Ngokomzekelo, i-resistor ye-0603 ilinganisa i-0.06 × 0.03 intshi.

Uzifunda njani iimpawu ze-SMD

Amacandelo amancinci asebenzisa iikhowudi zamanani okanye zealphanumeric. I-Resistors ihlala ibonisa amanani amadijithi amathathu, ngelixa i-diodes kunye ne-transistors ingaba neekhowudi ezinobumba ababini. Amaxwebhu edatha ayimfuneko ekuchongeni ngokuchanekileyo.

ImiGangatho yokupakisha kubo bonke abavelisi

Uninzi lwabavelisi balandela imigangatho yehlabathi efana neJEDEC kunye ne-IPC. Oku kuqinisekisa ukuhambelana kwaye kwenza ukukhangela kube lula kubo bonke ababoneleli. Iinjineli zinokuyila iiPCB ngokuzithemba, zisazi iindawo ezifumaneka ngokubanzi.

Izinto eziluncedo zokusebenzisa i-SMD

Unyawo oluncinci kunye noKhaphukhaphu

Amalungu e-SMDukunciphisa ubungakanani kunye nobunzima bezixhobo zombane. I-smartphone ayinakwenzeka nge-bulky through-hole resistors kunye ne-capacitors.

INdibano eKhawulezayo ngoomatshini bokuChola-kwaye-Indawo

Ubeko oluzenzekelayo luvumela amawaka amacandelo ukuba axhonywe ngeyure. Iimatshini zokukhetha kunye nendawo ziye zaba ngumqolo wemigca yemveliso ye-SMT, ukuhambisa zombini isantya kunye nokuchaneka.

Ukusebenza okuphezulu kunye neMfezeko yoMqondiso

Iindlela zombane ezimfutshane zinciphisa i-inductance kunye nokuchasana, okuphucula ukusebenza kwe-high-frequency. Oku kubalulekile kwizixhobo ezingenazingcingo kunye nonxibelelwano lwedatha olukhawulezayo.

I-PCB eMacaleni aMacala-mbini yokuKholeka

Ngenxa yokuba ii-SMDs azifuni imingxuma egrunjiweyo, amacandelo anokuxhonywa macala omabini ePCB. Oku kuphinda kabini indawo esebenzisekayo kwaye ixhasa uyilo olunoxinano oluphezulu.

Imingeni yeTekhnoloji ye-SMD

Ubunzima kwi-Soldering Manual kunye nokulungiswa

Ngelixa oomatshini bedibanisa ii-SMD ngokufanelekileyo, ukusebenza kwakhona ngesandla kunzima. Ubungakanani bazo obuncinci bufuna iimicroscopes kunye nezixhobo ezichanekileyo zokuthengisa.

Uvakalelo loBubushushu kunye neMiba yokuHambisa kwakhona

Ii-SMD zixhomekeke kwi-reflow soldering. Ukuba iiprofayili zobushushu azichanekanga, amacandelo angaqhekeka okanye angaphumeleli. Abavelisi kufuneka babeke iliso ngononophelo imijikelo yokufudumeza.

Imingeni yokuchonga ngenxa yobungakanani obuncinci

Iimpawu ze-SMD zihlala zincinci okanye zingabikho. Iinjineli zixhomekeke kwi-database, izixhobo zokukhulisa, kunye neendlela zokuvavanya ukuqinisekisa ukusetyenziswa kwenxalenye echanekileyo.

Ukusetyenziswa kwe-SMD kwi-Electronics yanamhlanje

I-Electronics yabathengi

Ii-smartphones, iitafile, iilaptops, kunye nezinto ezinxitywayo zonke zixhomekeke kakhulu kumacandelo e-SMD. Ubungakanani babo obubambeneyo benza uyilo oluncinci lwenzeke ngelixa uqinisekisa ukusebenza okuphezulu.

iiAutomotive kunye neAerospace Applications

Izithuthi zala maxesha zisebenzisa ii-SMDs kwiiyunithi zolawulo lwe-injini, ii-sensor, kunye ne-infotainment systems. Izixhobo ze-aerospace zixhamla ekusebenzeni kwazo okulula kunye nokuthembeka okuphezulu.

Izixhobo zonyango kunye ne-IoT Hardware

Ukusuka kwi-pacemakers ukuya kwizixhobo zokubeka iliso ezingenazingcingo, ii-SMD zenza iimveliso zonyango kunye ne-IoT zibe zincinci, zikrelekrele, kwaye zisebenzise amandla ngakumbi.

Izixhobo zoShishino kunye neeRobhothi

Iinkqubo ezizenzekelayo, iirobhothi, kunye nolawulo lwemizi-mveliso zonke zisebenzisa ii-SMDs ukuze zisebenze ngokuchanekileyo kunye nokuqina kwiindawo ezibango.

Inkqubo yokwenziwa kweSMD

Inkqubo yokwenziwa kweendibano ezisekelwe kwi-SMD ixhomekeke kwi-automation ephezulu kunye nolawulo olungqongqo lwekhwalithi. Ngokungafaniyo neendlela zemveli ezixhomekeke kakhulu kwi-soldering manual, imveliso ye-SMD iphantse izenzekele ngokupheleleyo. Oku kuqinisekisa zombini isantya esiphezulu kunye nomgangatho ongaguqukiyo.

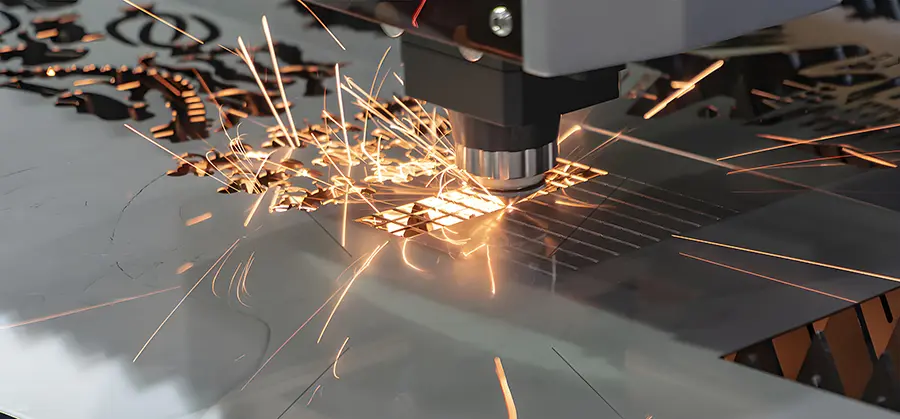

Uyilo lwePCB kunye neNgqwalaselo yoYilo

Inkqubo iqala ngeUyilo lwePCB. Iinjineli zisebenzisa izixhobo zoyilo ezincediswa yikhompyuter (CAD) ukwenza iziyilo ezilungiselelwe amacandelo aphezu komhlaba. Yonke iphedi, umkhondo, kunye nokudlula kucwangciswe ukujongana neemfuno zombane ezichanekileyo. Ngenxa yokuba izinto ze-SMD zincinci, imithetho yoyilo kufuneka iphendule ngesithuba, ukukhutshwa kwemaski ye-solder, kunye nokukhululeka kwe-thermal. Iimpazamo kweli nqanaba zingakhokelela ekungaphumelelini ngexesha lokuhlanganisana, ngoko ke ukulinganisa ngononophelo kunye nokuvavanya kubalulekile.

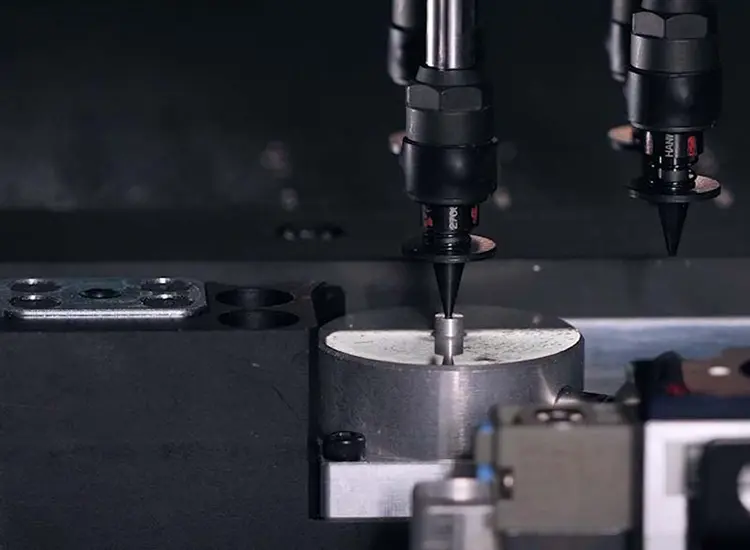

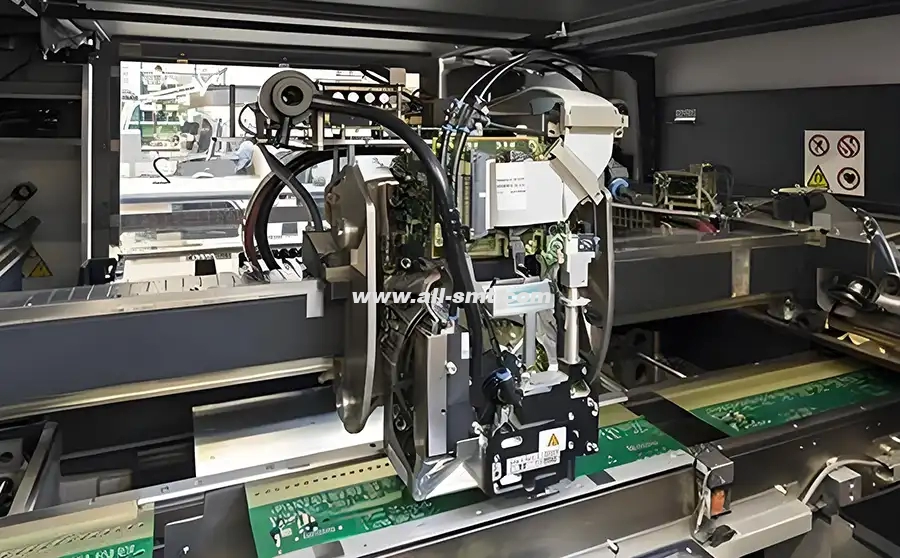

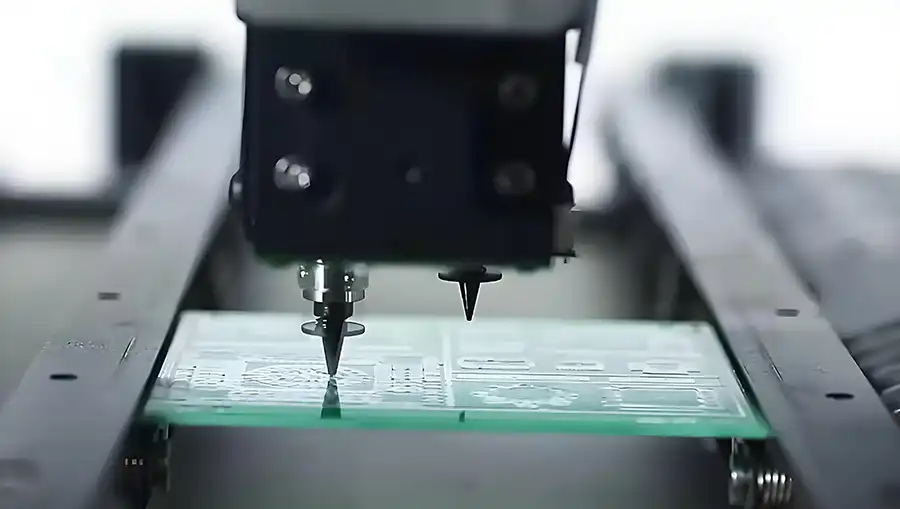

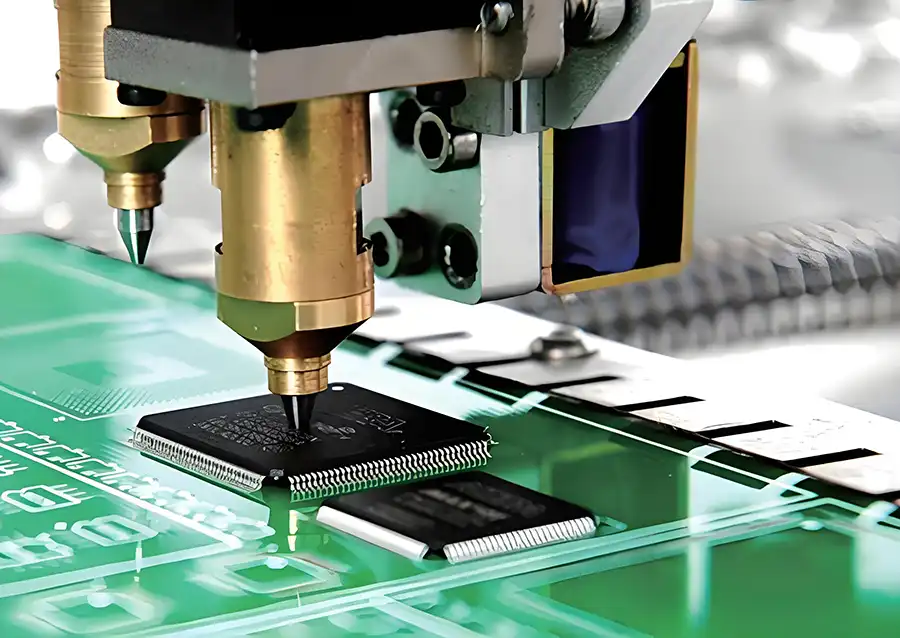

Khetha-ubeke oomatshini kwiNdibano ye-SMT

Nje ukuba iPCB ilungile, imveliso ihambela kwindibano ezenzekelayo.Khetha-ubeke oomatshinizintliziyo yemigca ye-SMT. Bakhetha izinto ze-SMD kwiireli, iitreyi, okanye iityhubhu, kwaye bazibeke kwi-PCB ngokuchaneka kwe-micrometer. Oomatshini abanesantya esiphezulu banokuphatha ngaphezulu kwe-100,000 yokubekwa ngeyure, ngelixa oomatshini bodidi oluphakathi bekulungele ukubaleka ibhetshi encinci okanye iprototype. Aba matshini bathembeleiinkqubo zombonoukulungisa ulungelelwaniso, ukuqinisekisa ukuba icandelo ngalinye lihlala ngokugqibeleleyo kwiphedi yalo phambi kokuba lifakwe kwi-soldering.

Izahlulo zoomatshini eziBalulekileyo zokuchola kunye nokubeka indawo kunye nezixhobo

Oomatshini bokuchola kunye nendawo basebenza ngokufanelekileyo kuphela xa bedityaniswe nelungeloizixhobo.

Abondlayo: Ukubonelela ngezinto ezivela kwiireli, izinti, okanye iitreyi. Iintlobo ezahlukeneyo zokutyisa zikhona kwiteyiphu, isambuku, kunye neendlela zonikezelo lokungcangcazela.

Imilomo: Izixhobo ezikhethekileyo zokufunxa ezibamba iinxalenye zobukhulu obahlukeneyo kunye neemilo. Abanye oomatshini batshintsha ngokuzenzekelayo imilomo ngokuxhomekeke kwindawo.

Iinkqubo zombono: Iikhamera kunye neenkqubo zamehlo ezikhokela ukubekwa, ukuhlola ukulungelelaniswa, kunye nokunciphisa iimpazamo.

Abahambisi: Hambisa ii-PCB phakathi kwezigaba zomgca wendibano.

Izixhobo zokulinganisa: Qinisekisa ukuchaneka ngokugcina ulungelelwaniso lomatshini kunye nokuchaneka kwe-feeder.

Isincedisi ngasinye sidlala indima ebalulekileyo. Ngaphandle kwee-feeders ezithembekileyo kunye nemilomo, nokuba umatshini ongcono kakhulu awukwazi ukufikelela kwiziphumo ezihambelanayo.

Reflow Soldering Inkqubo

Emva kokubekwa, iPCB iya ku areflow oven. Apha, intlama ye-solder isetyenzisiwe ngaphambili iyanyibilika kwaye ibophe izixhobo ebhodini. I-oveni ilandela inkangeleko yobushushu elawulwa ngononophelo enezigaba zokufudumeza, ukufunxwa, ukuqukuqela kwakhona, kunye nokupholisa. Ukuchaneka kubalulekile: ukutshisa kakhulu kunokonakalisa ii-SMD ezibuthathaka, ngelixa ukushisa ngaphantsi kubangela ukuba amalungu athambileyo e-solder.

Ulawulo loMgangatho kunye noHlolo

Ukuqinisekisa ukuthembeka, abavelisi basebenzisa iindlela ezininzi zokuhlola:

I-AOI(Uhlolo oluzenzekelayo lwaMacho)ijonga iindawo ezilahlekileyo okanye ezingekhoyo.

Ukuhlolwa kweX-reyiibhaqa iziphene ezifihliweyo ze-solder ezidibeneyo, ngakumbi phantsi kwe-BGAs (i-Ball Grid Arrays).

Uvavanyo lweSekethe (ICT)iqinisekisa ukusebenza kombane.

Ngokudibeneyo, ezi nkqubo ziqinisekisa ukuba indibano nganye ye-SMD ihlangabezana nemigangatho engqongqo yokusebenza.

Khetha-ubeke oomatshini kunye nezixhobo zabo

Khetha-ubeke oomatshinizifanelwe ingqwalasela eyodwa kuba zivumela ukuveliswa kombane wanamhlanje. Ngaphandle kwabo, ukudibanisa izinto ezincinci ze-SMD kwinqanaba lemizi mveliso ayinakwenzeka.

Yintoni umatshini wokuChola-ubeke?

Aumatshini wokukhetha kunye nendawoyinkqubo yerobhothi ezenzekelayo enyusela amacandelo e-SMD kwiiPCBs. Isebenzisa imilomo yokufunxa ukuchola iinxalenye kwi-feeders, ilungelelanise kusetyenziswa iikhamera, kwaye ibekwe ngokuchanekileyo kwiiphedi ze-solder. Oomatshini basuka kwimodeli yedesktop yenqanaba lokungena kwiprototyping ukuya kwiiyunithi zemizi-mveliso ezinesantya esiphezulu sokuvelisa ngobuninzi. Ukuchaneka kwazo, rhoqo phakathi kwe-±0.01 mm, kuzenza zibaluleke kakhulu kwii-electronics compact zanamhlanje.

Indlela yokuchola-kwaye-iNdawo oomatshini abaNqa iMixholo ye-SMD

Inkqubo iqala xa i-feeders ihambisa amacandelo. Intloko yomatshini ihamba ngokukhawuleza kwiPCB, ikhokelwa yisoftware kunye neenkqubo zombono. Inxalenye nganye iyaphakanyiswa, iqondiswe ngokuchanekileyo, kwaye ibekwe kwi-pad ene-solder paste. Iintloko ezininzi zinokusebenza ngaxeshanye, ukunciphisa ixesha lomjikelo. Oomatshini banamhlanje baphatha iinxalenye ezincinci njenge01005 iiphakheji—incinane kunokhozo lwesanti—ngelixa isagcine ukuchaneka okuphantse kugqibelele.

Izincedisi eziqhelekileyo kunye nezahlulo (Izondla, iiNozzles, iitreyi, iinqwelo)

Izixhobo ziqinisekisa ukusebenza kakuhle komatshini:

Abondlayo: Umqolo wonikezelo. I-tape feeders iphatha uninzi lwamalungu, ngelixa i-tray feeder ilawula ii-ICs ezinkulu.

Imilomo: Iingcebiso ezinokutshintshelana zokufunxa. Umatshini unokusebenzisa imilomo emininzi ngokuxhomekeke kwizinto ezahlukeneyo.

Iitreyi kunye neeNqwelo: Ukubonelela ngokugcinwa kwezinto ezinkulu okanye ezingaqhelekanga, ezihlala zidibene nokuphathwa okuzenzekelayo.

Izixhobo zoluvo: Khangela iimpazamo njengokukhetha kabini okanye izinto ezingekhoyo.

Izixhobo zokutshiza: Vumela ukondla okuqhubekayo ngokudibanisa iireel ezintsha kwezikhoyo, ukunciphisa ixesha lokuphumla.

Ezi zixhobo aziphuculi nje isantya kodwa zandisa isivuno kunye nokuthembeka.

Ukugcinwa kunye noTshintsho lwezahlulo zoomatshini

Njengazo zonke izixhobo ezichanekileyo, oomatshini bokukhetha kunye nendawo bafuna ukulungiswa rhoqo. Imilomo yomlomo iyaphela emva kwamawaka emijikelo, abondlayo banokuphulukana nokulungelelana, kwaye amabhanti okuhambisa afuna uhlengahlengiso. Iishedyuli zokukhusela zokukhusela zinciphisa ixesha lokuphumla. Iindawo ezisecaleni—ingakumbi ezondla kunye nemilomo—kufuneka zifumaneke lula ukuqinisekisa imveliso egudileyo.

Ukukhetha uMboneleli othembekileyo woKhetha-neNdawo oomatshini kunye neeNdawo

Ukukhetha umthengisi ofanelekileyo kubalulekile. Iqabane elithembekileyo aliboneleli nje ngoomatshini kodwa kwakhonainkonzo emva-intengiso, ukufumaneka iinxalenye, kunye nenkxaso yobugcisa. Izincedisi zomgunyathi zingumngcipheko kwimarike; ukuzisebenzisa kunokubangela iimpazamo zokubeka kunye nemiba yokuthembeka kwexesha elide. Iinkampani kufuneka zisebenze nababoneleli abathembekileyo abaqinisekisa ubunyani, babonelele ngeenkonzo zolungelelwaniso, kwaye banike uqeqesho kubaqhubi.

Uchonga njani amalungu e-SMD

Amacandelo e-SMD mancinci kakhulu, nto leyo eyenza ukuba uchongo lube ngumngeni, ngakumbi ngexesha lokulungiswa okanye ukwenza iprototyping. Iinjineli kunye neengcali zisebenzisa iindlela ezininzi zokuqinisekisa ukuqondwa kwenxalenye echanekileyo.

IiKhowudi zokuFunda kunye neeleyibhile

Uninzi lwe-SMD resistors kunye ne-capacitors zisebenzisaiikhowudi zamanani okanye zealphanumeric. Umzekelo, isixhasi esiphawulwe "472" sithetha 4,700 ohms. Ii-IC ezinkulu zihlala zinamanani acacileyo, ngelixa iitransistors ezincinci zinokubonisa nje oonobumba ababini okanye abathathu. Ezi mpawu zi-cross-referenced kunye ne-database yomenzi ukuze kuqinisekiswe.

Ukusebenzisa iiMultimeters kuVavanyo

Xa iikhowudi zingekho okanye zingacacanga, amagcisa athembeleuvavanyo multimeter. I-Resistors inokulinganiswa ngokuthe ngqo, i-capacitors ihlolwe i-capacitance, kunye ne-diode ihlolwe i-polarity. Le ndlela iqhelekile ngexesha lomsebenzi wokulungisa apho ii-database azikho.

Izixhobo zeReferensi kunye neeDatasheets zoMvelisi

Oovimba beenkcukacha ze-intanethi kunye neetshathi zereferensi eziprintiweyo zinceda ukucofa amanqaku e-SMD. Kwii-ICs kunye namacandelo akhethekileyo, ii-database zomenzi zihlala zingowona mthombo uthembekileyo. Banikezela ngeenkcukacha zombane, iiplani zepin, kunye neenkcukacha zokupakisha, ukuqinisekisa ukusetyenziswa okuchanekileyo.

I-SMD vs. THT (NgeTekhnoloji ye-Hole) Ukuthelekisa

Itekhnoloji ye-SMD ithathelwe indawo ngomngxuma kwizicelo ezininzi, kodwa zombini zisasebenza iindima ezizodwa. Ukuqonda ukungafani kwabo kunceda abaqulunqi bakhethe isisombululo esifanelekileyo.

UkuSebenza kweendleko

Indibano ye-SMD ngokuqhelekileyo ineendleko eziphezulu zokuvelisa umthamo ophezulu. Oomatshini abazenzekelayo babeka amawaka e-SMD ngokukhawuleza, behlisa iindleko zabasebenzi. Umngxuma wokutyhutyha, nangona kunjalo, usasetyenziswa kwi-volume ephantsi okanye kwiprototype yokwakha apho ukudibanisa ngesandla kwamkelekile.

Amandla oomatshini

Izinto eziphuma emngxunyeni zibonelela ngeebhondi zoomatshini ezomeleleyo kuba iinkokeli zabo zidlula kwi-PCB kunye ne-solder kumacala omabini. Oku kubenza bafaneleke ngakumbi kwizihlanganisi, iziguquli, okanye izinto ezivezwe kuxinzelelo lomatshini. Ngokwahlukileyo, i-SMD ixhomekeke kuphela kumalungu e-solder, abuthathaka phantsi kwamandla kodwa anele kwizicelo ezininzi.

Ukuthembeka kunye nokusebenza

Amacandelo e-SMD abonelela ngeendlela zombane ezimfutshane, ukunciphisa i-inductance kunye nokuphucula ukusebenza kwiifrikhwensi eziphezulu. Bakwavumela uyilo lwePCB enamacala amabini, ukwanda koxinzelelo. Iindawo ezinqumla kumngxuma zihlala ziluncedo kwiisekethe zamandla aphezulu kunye neendawo ezifuna ukuqina okugqithisileyo.

IiNdlela ezizayo kwiTekhnoloji ye-SMD

Itekhnoloji ye-SMD iyaqhubeka nokuvela njengoko i-elektroniki iba ncinci, ikhawuleza, kwaye idityaniswe ngakumbi. Iindlela ezininzi zokubumba ikamva lezixhobo eziphezu komhlaba kunye neendlela zokuhlanganisa.

I-Miniaturization kunye ne-Nano-SMD

Imfuno yezixhobo eziphathwayo nezinokunxitywa ziqhuba ngokuqhubekayoukwenziwa kweminiaturization. Izixhobo eziye zaqwalaselwa zincinci, njengeephakheji ze-0603, ngoku zitshintshwe yi-01005 okanye iipakethi ze-nano-SMD. Ezi zixhobo zincinci zivumela iinjineli ukuba zenze iimveliso ezixineneyo ezinje nge-smartwatches, ii-earbuds ezingenazingcingo, kunye nezixhobo zonyango ezinokumiliselwa.

I-Flexible kunye ne-Elektroniki eNxitywayo

Ii-elektroniki zexesha elizayo aziphelelanga kwii-PCB eziqinileyo.Iisekethe eziguquguqukayokunye neesubstrates ezinwebekayo zivumela amacandelo e-SMD ukuba axhonywe kwindawo egobileyo okanye enokunxitywa. Lo mkhwa unceda amashishini afana nokhathalelo lwempilo, apho izinzwa ezidityaniswe kwimpahla okanye iziziba zesikhumba zibonelela ngokubeka iliso kwezempilo okuqhubekayo.

I-AI kunye ne-Automation kwiNdibano ye-SMT

Oomatshini bokuchola kunye nendawo baya besiba nobuchule. Ngokudityaniswa kwekukubhadla okungeyonyani, oomatshini banokuzilinganisa ngokwabo, babone ukuqhelaniswa necandelo ngokukhawuleza, kunye nokwandisa iindlela zokubeka ngexesha lokwenyani. Ukugcinwa okuqikelelwayo kukwanciphisa ixesha lokuphumla, njengoko i-AI algorithms ibeka esweni i-fiders, imilomo, kunye neenkqubo zombono zeempawu zokuqala zokunxiba.

Uveliso oluZinzileyo kunye naMalunga aMahla okuKhokelo

Imithetho yokusingqongileyo iyanyanzelisaiindlela zokuhlanganisa eco-friendly. I-solder engenalodi, izinto ezinokuphinda zisetyenziswe, kunye nee-oveni zokuphinda zisebenze ngokufanelekileyo zisemgangathweni ngoku. Abavelisi bakwagxile ekunciphiseni inkunkuma ngexesha lokusekwa kwesondlo kunye nokwandisa ukusetyenziswa koomatshini ukwenzela imveliso eluhlaza.

Ukudibanisa ne-IoT kunye ne-5G

Njengoko iinethiwekhi ze-5G zanda kwaye izixhobo ze-IoT zanda, amacandelo e-SMD kufuneka aphathe ama-frequencies aphezulu kunye nokusetyenziswa kwamandla aphantsi. Uyilo oluphucukileyo lwe-SMD lubonelela ngentembeko yophawu olungcono, ixhasa yonke into ukusuka kwizithuthi ezizimeleyo ukuya kwizixeko ezikrelekrele.

Isikhokelo sokuthenga kumacandelo e-SMD

Ukukhetha amacandelo e-SMD afanelekileyo kubalulekile kuphuhliso oluyimpumelelo lwemveliso kunye nokuveliswa. Isicwangciso sokuthenga esicingayo siqinisekisa zombini umgangatho kunye nokusebenza kakuhle kweendleko.

Ukukhetha uMboneleli oLungileyo

Ababoneleli bayahluka ngokuthembeka, ukufumaneka kwempahla, kunye nenkonzo emva kokuthengisa. Umthengisi othembekileyo akaboneleli kuphela ngezinto kodwa kwakhonaukulandeleka kunye neziqinisekisoukubonisa ubunyani. Ukusebenza nabasasazi abagunyazisiweyo kunciphisa umngcipheko weemveliso zomgunyathi ezinokubeka esichengeni ukuthembeka kwesixhobo.

Imiba echaphazela ixabiso kunye nokufumaneka

Amaxabiso e-SMD axhomekeke kuhlobo lwecandelo, ubungakanani bephakheji, kunye neemeko zobonelelo zehlabathi. Ukunqongophala kweemarike, ezifana nezo zibonwa ngexesha leengxaki ze-semiconductor, kunokunyusa iindleko kakhulu. Iinjineli kufuneka zicwangcise iindlela zokukhangela kwangethuba kwisigaba soyilo, zithathela ingqalelo ezinye iindawo xa kunokwenzeka.

Ukunqanda Izixhobo ze-SMD zomgunyathi

Ii-SMD zomgunyathi ziyingxaki ekhulayo kushishino lombane. Ezi nxalenye zinokubonakala zifana kodwa zihlala zisilela phantsi koxinzelelo. Ukuziphepha, iinkampani kufuneka zithenge kuphela kubaboneleli abagunyazisiweyo, zijonge iimpawu zecandelo ngononophelo, kwaye zisebenziseUkuhlolwa kweX-reyiokanyeukuqhawuka kwentlokoubuchule beendawo ezibalulekileyo.

Ukuthengwa kwezinto ezininzi kunye noLungiselelo

Kwimveliso ephezulu, ukuthengwa kwezinto ezininzi kunciphisa iindleko kwiyunithi nganye. Ababoneleli bahlala bebonelela ngeereli okanye iitreyi ezilungiselelwe oomatshini bokuchola kunye nendawo, beqinisekisa ukutya okugudileyo ngexesha lokudityaniswa. Ulungiselelo lukwabalulekile-ukukhetha ababoneleli bengingqi kunciphisa amaxesha okukhokela kwaye kunciphisa umngcipheko wokuhambisa ngenqanawa.

Itekhnoloji ye-SMD ilawula i-elektroniki yanamhlanje kuba inikezela uyilo olubambeneyo, ukusebenza kakuhle kweendleko, kunye nokusebenza okuphezulu. Ukusuka kwizichasi ezincinci ukuya kwiisekethe ezidityanisiweyo eziphambili, izixhobo ze-SMD zinika amandla yonke into ukusuka kwii-smartphones ukuya kwizixhobo zonyango. Ukusetyenziswa koomatshini bokukhetha kunye nezixhobo zabo kwenza isantya esiphezulu, ukuveliswa kwevolumu ephezulu kunokwenzeka, ngelixa ukukhangela ngokucophelela kunye nokuhlolwa kuqinisekisa ukuthembeka. Njengoko i-elektroniki iqhubeka nokuvela, i-SMD iya kuhlala isembindini wokwenza izinto ezintsha, ukuqhuba i-miniaturization, i-automation, kunye nezixhobo ezikrelekrele kwixesha elizayo.