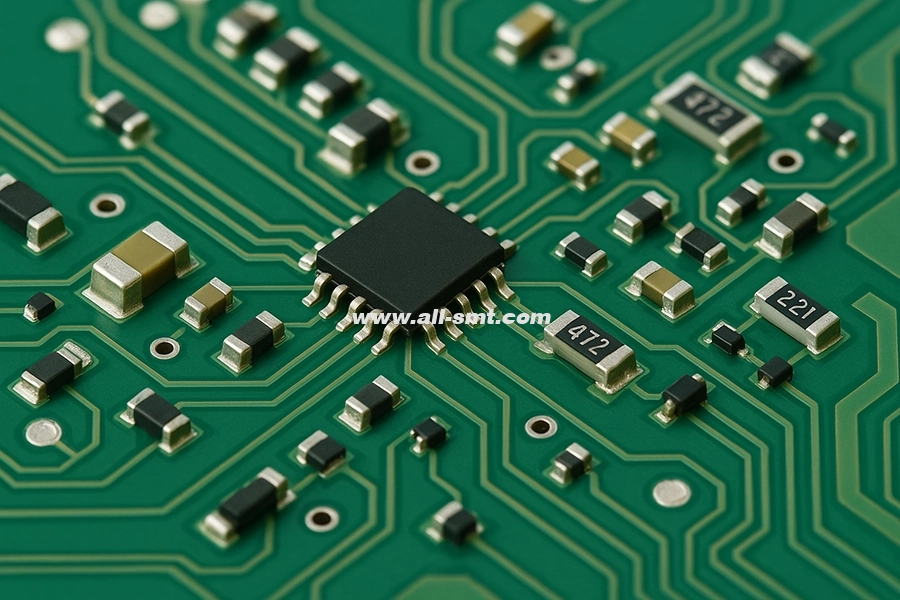

A Surface-Mount Device (SMD) is an electronic component designed to be mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole components that require drilled holes, SMDs are placed and soldered on flat copper pads. This method saves space, reduces weight, and enables high-density circuit designs. SMD technology became the foundation of modern electronics because it allows automated assembly using pick-and-place machines, which position thousands of components with speed and accuracy. Common SMDs include resistors, capacitors, diodes, transistors, and integrated circuits, all of which are present in everyday devices like smartphones, laptops, and medical equipment.

Understanding SMD Technology

Definition of Surface-Mount Device (SMD)

An SMD is a miniaturized component optimized for surface-mount technology (SMT). These devices come without long leads; instead, they use short metal contacts that rest directly on solder pads. Their compact size allows engineers to fit more circuits on smaller PCBs, which is essential for modern portable electronics.

The Difference Between SMD and Through-Hole Technology

Through-hole components require drilling holes into the PCB, which consumes space and limits design flexibility. SMD components, by contrast, are attached directly to the surface. This change significantly increases component density and reduces manufacturing costs. For example, a smartphone with millions of transistors can only exist because of SMD and SMT assembly processes.

Why SMD Became the Industry Standard

SMD technology gained popularity in the 1980s, when manufacturers sought ways to miniaturize products while improving performance. Automated assembly using pick-and-place machines made SMD mass production cost-effective. Today, more than 90% of electronic assemblies worldwide rely on SMT, making SMD components the global standard.

History and Evolution of SMD

Early Days of PCB Assembly

Before SMD, electronic assemblies were bulky and less efficient. Engineers used through-hole technology to secure components with long leads. While mechanically strong, these assemblies limited design density and slowed down production.

Transition from Through-Hole to SMD in the 1980s

The shift toward consumer electronics created demand for smaller, lighter, and cheaper devices. This led to the introduction of surface-mount technology. Japanese manufacturers were among the first to adopt SMT, quickly proving its benefits in televisions, radios, and industrial systems.

Modern Developments in SMT

Today’s SMT production lines use high-speed pick-and-place machines capable of placing over 100,000 components per hour. Advanced vision systems ensure accuracy even with microscopic parts, while reflow soldering provides consistent, high-quality connections. The combination of SMD components and automated assembly continues to push electronics toward miniaturization and efficiency.

Types of SMD Components

SMD Resistors

SMD resistors regulate current flow in circuits. They are marked with numerical codes (e.g., 103 = 10kΩ). Their compact design allows easy placement on PCBs, supporting both analog and digital systems.

SMD Capacitors

Capacitors store and release energy. In SMD form, they appear as small rectangular blocks, commonly made from ceramic or tantalum. They stabilize voltage and filter noise in smartphones, computers, and power supplies.

SMD Diodes

SMD diodes control current direction. They are widely used in rectification, signal protection, and light emission (LEDs). Their small size allows integration into compact devices without sacrificing reliability.

SMD Transistors

Transistors act as switches or amplifiers. In SMD format, they enable power management and signal processing in portable electronics. Modern processors rely on billions of these tiny transistors.

SMD Integrated Circuits (ICs)

Integrated circuits are complex assemblies of transistors, resistors, and capacitors within a single package. SMD ICs make possible microcontrollers, processors, and memory chips that drive advanced technology.

Specialized SMD Components

Other specialized parts include inductors, quartz crystals, and LEDs. Each plays a role in frequency control, energy storage, or visual signaling. Their SMD versions enhance performance while reducing space requirements.

SMD Package Codes and Sizes

Common SMD Codes

SMD components are identified by package sizes, such as 0402, 0603, 0805, and 1206. The numbers represent length and width in hundredths of an inch. For example, a 0603 resistor measures 0.06 × 0.03 inches.

How to Read SMD Markings

Small components use numeric or alphanumeric codes. Resistors often show three-digit numbers, while diodes and transistors may have two-letter codes. Datasheets are essential for accurate identification.

Package Standards Across Manufacturers

Most manufacturers follow international standards like JEDEC and IPC. This ensures compatibility and makes sourcing easier across suppliers. Engineers can design PCBs confidently, knowing parts are widely available.

Advantages of Using SMD

Smaller Footprint and Lightweight

SMD parts reduce the size and weight of electronic devices. A smartphone would be impossible with bulky through-hole resistors and capacitors.

Faster Assembly with Pick-and-Place Machines

Automated placement allows thousands of components to be mounted per hour. Pick-and-place machines have become the backbone of SMT production lines, delivering both speed and accuracy.

Higher Performance and Signal Integrity

Shorter electrical paths reduce inductance and resistance, which improves high-frequency performance. This is critical for wireless devices and fast data communication.

Double-Sided PCB Mounting Capability

Because SMDs do not require drilled holes, components can be mounted on both sides of the PCB. This doubles usable space and supports higher-density designs.

Challenges of SMD Technology

Difficulties in Manual Soldering and Repair

While machines assemble SMDs efficiently, manual rework is challenging. Their tiny size requires microscopes and precision tools for soldering.

Heat Sensitivity and Reflow Issues

SMDs rely on reflow soldering. If temperature profiles are incorrect, components can crack or fail. Manufacturers must carefully monitor heating cycles.

Identification Challenges Due to Small Size

SMD markings are often tiny or absent. Engineers rely on datasheets, magnification tools, and testing methods to ensure correct part usage.

Applications of SMD in Modern Electronics

Consumer Electronics

Smartphones, tablets, laptops, and wearables all rely heavily on SMD components. Their compact size makes slim designs possible while ensuring high functionality.

Automotive and Aerospace Applications

Modern vehicles use SMDs in engine control units, sensors, and infotainment systems. Aerospace equipment benefits from their lightweight and high-reliability performance.

Medical Devices and IoT Hardware

From pacemakers to wireless monitoring devices, SMDs make medical and IoT products smaller, smarter, and more energy efficient.

Industrial Equipment and Robotics

Automation systems, robotics, and industrial controls all use SMDs for precise operation and durability in demanding environments.

SMD Manufacturing Process

The manufacturing process of SMD-based assemblies relies on advanced automation and strict quality control. Unlike traditional methods that depend heavily on manual soldering, SMD production is almost entirely automated. This ensures both high speed and consistent quality.

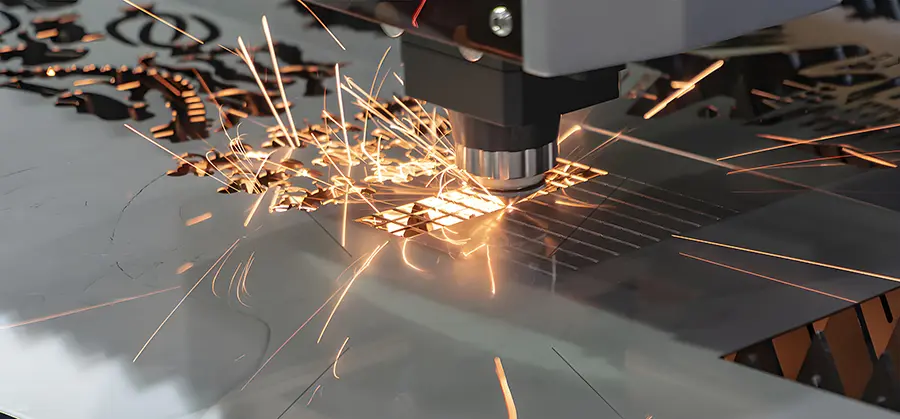

PCB Design and Layout Considerations

The process starts with PCB design. Engineers use computer-aided design (CAD) tools to create layouts optimized for surface-mount components. Every pad, trace, and via is planned to handle precise electrical requirements. Because SMD components are small, design rules must account for spacing, solder mask clearances, and thermal relief. Mistakes at this stage can lead to failure during assembly, so careful simulation and testing are essential.

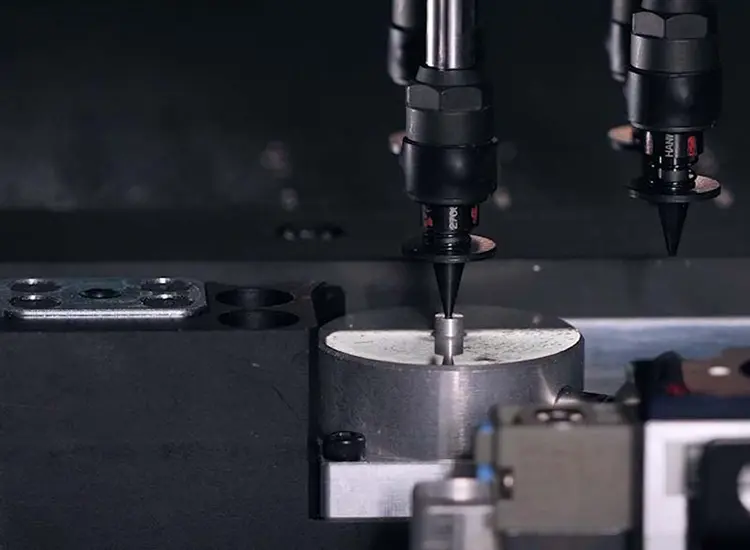

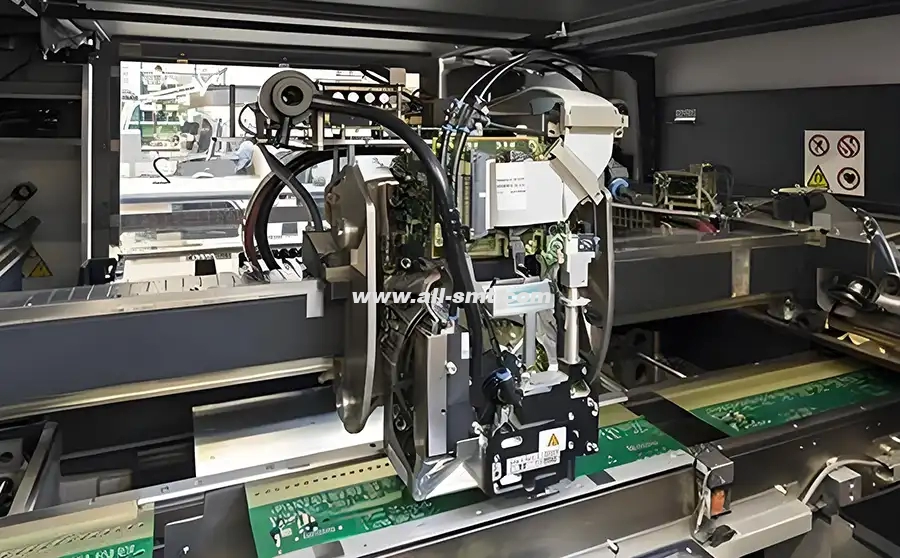

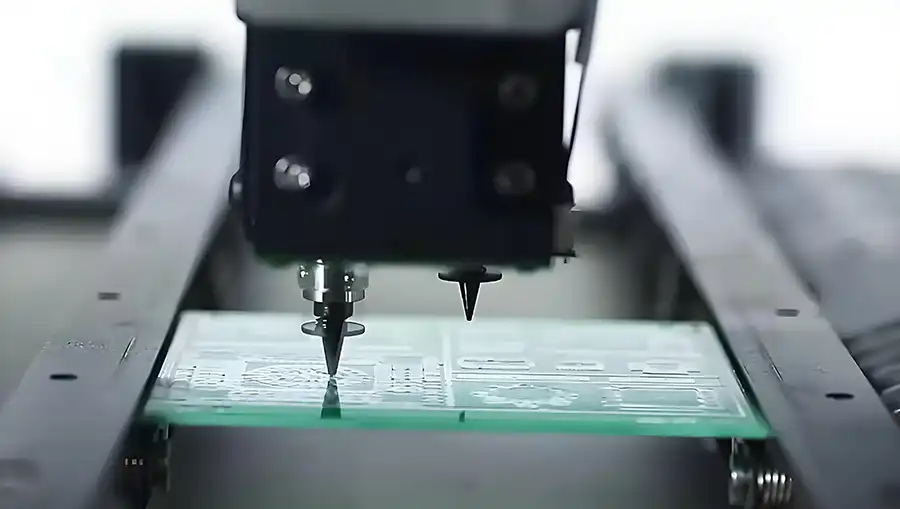

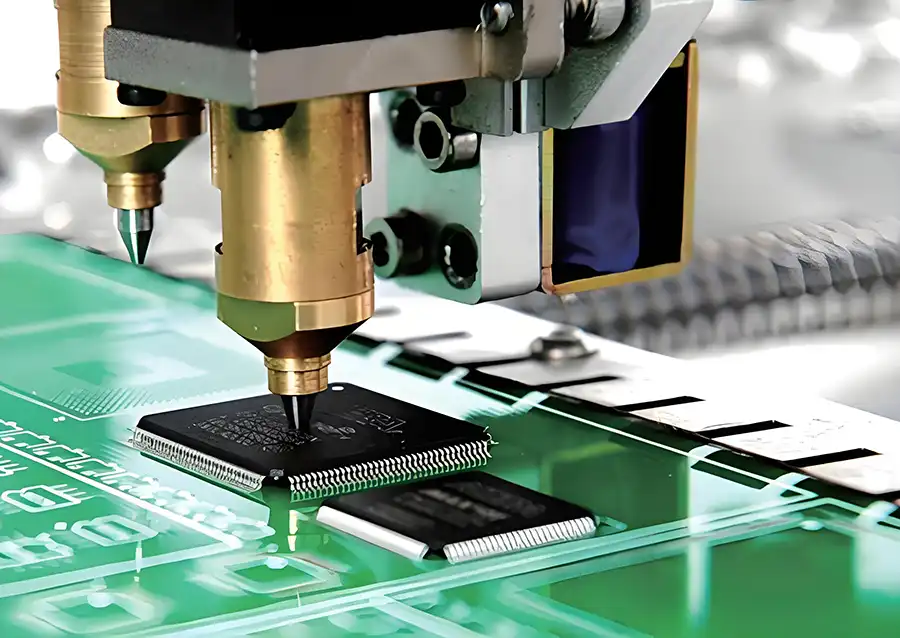

Pick-and-Place Machines in SMT Assembly

Once the PCB is ready, production moves to automated assembly. Pick-and-place machines are the heart of SMT lines. They pick SMD components from reels, trays, or tubes, and place them on the PCB with micrometer precision. High-speed machines can handle over 100,000 placements per hour, while mid-range machines are ideal for small-batch or prototype runs. These machines rely on vision systems to correct alignment, ensuring each component sits perfectly on its pad before soldering.

Essential Pick-and-Place Machine Parts and Accessories

Pick-and-place machines function effectively only when paired with the right accessories.

Feeders: Supply components from reels, sticks, or trays. Different feeders exist for tape, bulk, and vibratory supply methods.

Nozzles: Specialized suction tools that grip components of different sizes and shapes. Some machines automatically swap nozzles depending on the part.

Vision Systems: Cameras and optical systems that guide placement, inspect alignment, and reduce errors.

Conveyors: Move PCBs between stages of the assembly line.

Calibration Tools: Ensure accuracy by maintaining machine alignment and feeder precision.

Each accessory plays a vital role. Without reliable feeders and nozzles, even the best machine cannot achieve consistent results.

Reflow Soldering Process

After placement, the PCB moves to a reflow oven. Here, solder paste applied earlier melts and bonds the components to the board. The oven follows a carefully controlled temperature profile with stages of preheating, soaking, reflow, and cooling. Precision is crucial: overheating can damage sensitive SMDs, while underheating causes weak solder joints.

Quality Control and Inspection

To guarantee reliability, manufacturers apply multiple inspection techniques:

AOI (Automated Optical Inspection) checks for misplaced or missing parts.

X-ray Inspection detects hidden solder joint defects, especially under BGAs (Ball Grid Arrays).

In-Circuit Testing (ICT) verifies electrical performance.

Together, these processes ensure each SMD assembly meets strict performance standards.

Pick-and-Place Machines and Their Accessories

Pick-and-place machines deserve special attention because they enable modern electronics production. Without them, assembling tiny SMD components at industrial scale would be impossible.

What Is a Pick-and-Place Machine?

A pick-and-place machine is an automated robotic system that mounts SMD components onto PCBs. It uses suction nozzles to pick up parts from feeders, aligns them using cameras, and places them precisely on solder pads. Machines range from entry-level desktop models for prototyping to high-speed industrial units for mass production. Their accuracy, often within ±0.01 mm, makes them essential for today’s compact electronics.

How Pick-and-Place Machines Mount SMD Components

The process begins when feeders deliver components. The machine head moves quickly across the PCB, guided by software and vision systems. Each part is lifted, oriented correctly, and placed on a pad with solder paste. Multiple heads may work simultaneously, reducing cycle time. Modern machines handle parts as small as 01005 packages—smaller than a grain of sand—while still maintaining near-perfect accuracy.

Common Accessories and Parts (Feeders, Nozzles, Trays, Carts)

Accessories ensure smooth machine operation:

Feeders: The backbone of supply. Tape feeders handle the majority of parts, while tray feeders manage larger ICs.

Nozzles: Interchangeable tips for suction. A machine may use dozens of nozzles depending on component diversity.

Trays and Carts: Provide storage for larger or irregular components, often combined with automated handling.

Component Sensors: Detect errors like double picks or missing components.

Splicing Tools: Allow continuous feeding by joining new reels to existing ones, reducing downtime.

These accessories not only improve speed but also maximize yield and reliability.

Maintenance and Replacement of Machine Parts

Like all precision equipment, pick-and-place machines require regular maintenance. Nozzles wear out after thousands of cycles, feeders may lose alignment, and conveyor belts need adjustment. Preventive maintenance schedules reduce downtime. Spare parts—especially feeders and nozzles—must be readily available to ensure smooth production.

Choosing a Reliable Supplier for Pick-and-Place Machines and Parts

Selecting the right supplier matters. A reliable partner provides not just machines but also after-sales service, spare parts availability, and technical support. Counterfeit accessories are a risk in the market; using them can cause placement errors and long-term reliability issues. Companies should work with trusted suppliers who guarantee authenticity, provide calibration services, and offer training for operators.

How to Identify SMD Components

SMD components are extremely small, which makes identification challenging, especially during repair or prototyping. Engineers and technicians use several methods to ensure correct part recognition.

Reading Codes and Labels

Many SMD resistors and capacitors use numerical or alphanumeric codes. For example, a resistor marked “472” means 4,700 ohms. Larger ICs often have clear part numbers, while smaller transistors may display just two or three letters. These markings are cross-referenced with manufacturer datasheets for confirmation.

Using Multimeters for Testing

When codes are missing or unclear, technicians rely on multimeter testing. Resistors can be measured directly, capacitors tested for capacitance, and diodes checked for polarity. This approach is common during repair work where datasheets are unavailable.

Reference Tools and Manufacturer Datasheets

Online databases and printed reference charts help decode SMD markings. For ICs and specialized parts, manufacturer datasheets remain the most reliable source. They provide electrical specifications, pin layouts, and packaging details, ensuring correct application.

SMD vs. THT (Through-Hole Technology) Comparison

SMD technology replaced through-hole in most applications, but both still serve unique roles. Understanding their differences helps designers choose the right solution.

Cost Efficiency

SMD assembly is generally more cost-efficient for high-volume production. Automated machines place thousands of SMDs quickly, lowering labor costs. Through-hole, however, is still used in low-volume or prototype builds where hand assembly is acceptable.

Mechanical Strength

Through-hole components offer stronger mechanical bonds since their leads pass through the PCB and solder on both sides. This makes them more suitable for connectors, transformers, or components exposed to mechanical stress. In contrast, SMD relies solely on solder joints, which are weaker under force but sufficient for most applications.

Reliability and Performance

SMD components provide shorter electrical paths, reducing inductance and improving performance at high frequencies. They also allow double-sided PCB design, increasing density. Through-hole parts remain useful for high-power circuits and environments requiring extreme durability.

Future Trends in SMD Technology

SMD technology continues to evolve as electronics become smaller, faster, and more integrated. Several trends are shaping the future of surface-mount devices and assembly methods.

Miniaturization and Nano-SMD

The demand for portable and wearable devices drives continuous miniaturization. Components once considered small, like 0603 packages, are now replaced by 01005 or even nano-SMD packages. These tiny devices allow engineers to design ultra-compact products such as smartwatches, wireless earbuds, and implantable medical devices.

Flexible and Wearable Electronics

Future electronics are not limited to rigid PCBs. Flexible circuits and stretchable substrates allow SMD components to be mounted on curved or wearable surfaces. This trend benefits industries like healthcare, where sensors integrated into clothing or skin patches provide continuous health monitoring.

AI and Automation in SMT Assembly

Pick-and-place machines are becoming smarter. With the integration of artificial intelligence, machines can self-calibrate, detect component orientation faster, and optimize placement paths in real time. Predictive maintenance also reduces downtime, as AI algorithms monitor feeders, nozzles, and vision systems for early signs of wear.

Sustainable Manufacturing and Lead-Free Components

Environmental regulations push for eco-friendly assembly methods. Lead-free solder, recyclable materials, and energy-efficient reflow ovens are now standard. Manufacturers also focus on reducing waste during feeder setup and optimizing machine utilization for greener production.

Integration with IoT and 5G

As 5G networks expand and IoT devices multiply, SMD components must handle higher frequencies and lower power consumption. Advanced SMD designs provide better signal integrity, supporting everything from autonomous vehicles to smart cities.

Buying Guide for SMD Components

Choosing the right SMD components is crucial for successful product development and manufacturing. A thoughtful buying strategy ensures both quality and cost-effectiveness.

Choosing the Right Supplier

Suppliers vary in reliability, stock availability, and after-sales service. A trusted supplier provides not only components but also traceability and certifications to prove authenticity. Working with authorized distributors reduces the risk of counterfeit products that could compromise device reliability.

Factors Affecting Price and Availability

SMD prices depend on component type, package size, and global supply conditions. Market shortages, such as those seen during semiconductor crises, can increase costs dramatically. Engineers should plan sourcing strategies early in the design phase, considering alternative parts when possible.

Avoiding Counterfeit SMD Components

Counterfeit SMDs are a growing problem in the electronics industry. These parts may look identical but often fail under stress. To avoid them, companies should purchase only from authorized suppliers, check component markings carefully, and use X-ray inspection or decapsulation techniques for critical parts.

Bulk Purchasing and Logistics

For high-volume production, bulk purchasing reduces cost per unit. Suppliers often provide reels or trays optimized for pick-and-place machines, ensuring smooth feeding during assembly. Logistics also matter—choosing regional suppliers shortens lead times and reduces shipping risks.

SMD technology dominates modern electronics because it delivers compact design, cost efficiency, and superior performance. From tiny resistors to advanced integrated circuits, SMD components power everything from smartphones to medical devices. The use of pick-and-place machines and their accessories makes high-speed, high-volume production possible, while careful sourcing and inspection ensure reliability. As electronics continue to evolve, SMD will remain at the center of innovation, driving miniaturization, automation, and smarter devices for the future.