ASM SIPLACE X2S waa mashiinka meelaynta moodeelka ah ee dhexdhexaadka ah iyo xawaaraha sare leh ee ay daahfurtay ASM Assembly Systems (oo hore u ahaan jiray Siemens Electronics Assembly Division). Waxay ka kooban tahay dabacsanaan, saxsanaan sare iyo sahlan isticmaalka, waxayna ku habboon tahay dufcad yar iyo mid dhexdhexaad ah, xaalado wax soo saar elektaroonig ah oo kala duwan, sida qalabka elektiroonigga ah ee macaamiisha, qalabka elektiroonigga baabuurta, xakamaynta warshadaha, iwm.

Meelaynta suuqa:

✔ Shirkadaha EMS ee yaryar iyo kuwa dhexdhexaadka ah

✔ Wax soo saarka isku dhafan ee sarreeya

✔ R&D iyo wax soo saar tijaabo ah oo yar yar

II. Tilmaamaha asaasiga ah iyo xuduudaha farsamada

Tilmaamayaasha X2S

Xawaaraha meelaynta 30,000 - 60,000 CPH (waxay kuxirantahay qaabeynta)

Saxnaanta meelaynta ± 25μm @3σ (waxay taageertaa qaybaha 01005)

Qaybaha kala duwan ee 01005 ~ 50mm × 50mm

Awoodda quudiyaha ilaa 120 (cajalad 8mm)

Cabbirka substrate-ka 50mm × 50mm ~ 510mm × 460mm

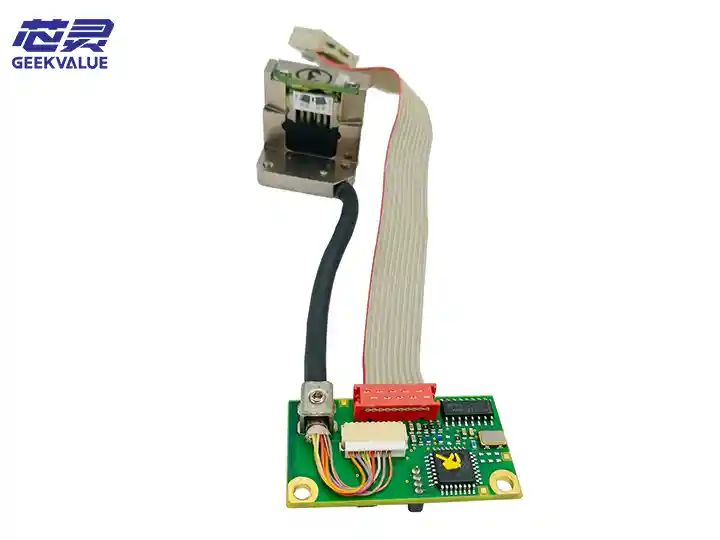

Nidaamka aragga 5MP HD kamarad + iftiin badan oo muuqaal ah

Qalabka software ee SIPLACE Pro / ASM OMS

III. Hawlaha muhiimka ah iyo sifooyinka

1. Meelaynta xawaaraha sare iyo saxnaanta sare

Xawaaraha aragtidu wuxuu gaaraa 60,000 CPH, oo ku haboon dufcadaha yaryar iyo kuwa dhexdhexaadka ah iyo wax soo saarka hufan.

± 25μm saxnaanta, waxay taageertaa qaybaha saxda ah sida 01005, 0201, 0.3mm garoonka QFN.

2. Naqshad qaabaysan

Ikhtiyaar ah hal-madax/qaabaynta madax-badan, dabacsan si wax looga qabto qaybaha kala duwan (sida iska caabiyeyaasha, BGA, xidhayaasha).

Isbedelka khadka degdega ah (<10 daqiiqo), yaraynta wakhtiga dhimista.

3. Nidaamka quudinta caqliga

Quudiye Smart: Si toos ah u aqoonso booska suunka walxaha si loo yareeyo wax tuurista.

Quudinta laba-track (ikhtiyaar): Ma xidhitaanno inta lagu jiro isbeddelka shay, hagaaji waxtarka.

4. Nidaamka aragga sare

5MP HD kamarad + iftiinka xagal badan, aqoonsiga saxda ah ee qaybaha milicsiga iyo madow.

Aragtida Duullimaadka: Sixitaan firfircoon, hoos u dhigista wakhtiga.

5. Wax-soo-saarka garaadka

Software-ka ASM OMS: Wanaaji dariiqa meelaynta oo wanaaji hufnaanta 10%-20%.

Taageerada warshadaha 4.0: Isdhexgalka nidaamka MES/ERP si loo gaaro raadinta xogta.

4. Xaaladaha codsiga caadiga ah

Electronics-ka macaamiisha ah: Motherboard-ka casriga ah (01005 qaybaha).

Qalabka elektiroonigga ah: guddiga kontoroolka ECU (QFN, BGA).

Xakamaynta warshadaha: Qaybta PLC (isku xidhaha qaabaysan ee gaarka ah).

Qalabka caafimaadka: looxa dareenka saxda ah ee saxda ah.

5. Hababka dayactirka

1. Dayactirka maalinlaha ah

Maalin kasta:

Nadiifi tuubada iyo muraayada kamarada.

Hubi in shaandhada faakuumka la xidhay iyo in kale.

Todobaadle:

Saliid xadiidka hagaha dhidibka X/Y iyo boolasha rasaasta.

Cabbir tallaabada quudiyaha.

2. Is-habaynta xilliyeed

Bishii:

Samee jaangooynta nidaamka muuqaalka (adoo isticmaalaya guddiga cabbirka caadiga ah).

Hubi cadaadiska dhidibka Z ee madaxa meelaynta.

3. Liiska qaybaha furaha

Nozzle (gaar ah 01005/0402).

dhaliye vacuum.

Qalabka quudinta/suunka.

VI. Cilladaha caadiga ah iyo fikradaha dayactirka

1. Kordhinta kor u kaca

Sababaha suurtagalka ah:

Nozzles waa xiran yahay/xiran yahay → Nadiifi ama bedel sanbabada.

weecasho muuqaal ah → Dib u habeyn ku samee kamarada.

Meelaynta PCB waa khalad → Hubi PIN taageerada

Xalka:

Fulin Qalabaynta Automatic

Hubi halbeegyada maktabadda qaybta ( dhumucda, cabbirka).

2. Heerka tuurista sare

Sababaha suurtagalka ah:

Faakuum aan ku filnayn (noosku wuu xidhan yahay/tubooyinka hawadu soo daataan) → Hubi bamka faakuumka (heerka> 80kPa).

Khaladka talaabada quudiyaha → Dib u habeyn quudiyaha.

Aqoonsiga qaybaha ayaa fashilmay → Hagaaji cabbirrada iftiinka.

Xalka:

Nadiifi tuubada oo hubi khadka faakuumka.

Wanaaji halbeegyada aqoonsiga muuqaalka (sida ku darida iftiinka dhinaca).

3. Alaarmiga mashiinka (khalad servo/drive)

Sababaha suurtagalka ah:

Culayska baabuurka → Hubi saliidaynta tareenada hagaha.

Incoder failure → Dib u billow ama beddel khadka cod-bixiyaha.

Korontadu way isbedeshaa → Hubi danab saddex waji ah.

Xalka:

Hubi lambarka qaladka (sida E-stop, Axis Error).

Gacanta ku riix dhidibka X/Y si aad u hubiso inay ku dheggan tahay.

4. Quudiyaha ma quudiyo

Sababaha suurtagalka ah:

Cajaladda ayaa ku dheggan → Gacanta u soo jiid walxaha si aad uga saarto walxaha ku dheggan.

Dareemuhu waa wasakh → Nadiifi dareeraha korantada.

Xidhiidh koronto oo liidata → Dib u celi khadka signalka.

Xalka:

Hubi in qalabka quudiyaha uu toosan yahay.

Beddel qalabka quudiyaha ee dhaawacmay.

VII. Soo koobid

ASM SIPLACE X2S waa mashiinka meelaynta xawaaraha dhexdhexaadka ah kharash-ool ah oo dabacsan oo ku habboon dufcad yar iyo mid dhexdhexaad ah iyo baahiyo wax soo saar oo kala duwan. Naqshaddeeda qaabaysan, nidaamka quudinta caqliga leh iyo aragti sax ah ayaa ka dhigaysa doorashada ugu habboon ee wax soo saarka elektaroonigga ah.

Qodobbada muhiimka ah ee dayactirka:

✔ Dayactirka joogtada ahi wuxuu yarayn karaa 80% guuldarrada.

✔ Dhibaatooyinka adag, waxaa lagu talinayaa inaad la xiriirto ASM taageero farsamo oo rasmi ah.

Macluumaad dheeraad ah oo faahfaahsan, fadlan tixraac Buugga Adeegga SIPLACE X2S ama ka hel taageero aaladda ogaanshaha fog ee ASM.