ASM SIPLACE X2S kyuma kya sipiidi ya wakati n’eky’amaanyi eky’okuteeka ebintu mu ngeri ya modulo ekyatongozebwa kkampuni ya ASM Assembly Systems (eyali Siemens Electronics Assembly Division). Eriko obusobozi obukyukakyuka, obutuufu obw’amaanyi n’obwangu okukozesa, era esaanira ebitundu ebitono n’ebya wakati, embeera z’okukola ebyuma eby’enjawulo, gamba ng’ebyuma ebikozesebwa, ebyuma by’emmotoka, okufuga amakolero, n’ebirala.

Ensengeka y’akatale:

✔ Kkampuni entonotono n’eza wakati eza EMS

✔ Okufulumya okutabula kwa waggulu

✔ R&D n’okufulumya okugezesa mu bitundu ebitono

II. Core specifications ne parameters ez’ekikugu

Parameters X2S ebikwata ku nsonga eno

Sipiidi y’okuteeka 30,000 - 60,000 CPH (okusinziira ku nsengeka)

Obutuufu bw’okuteeka ±25μm @3σ (buwagira ebitundu 01005)

Ebitundu ebitali bimu 01005 ~ 50mm × 50mm

Obusobozi bw’okuliisa Okutuuka ku 120 (8mm tape)

Sayizi ya substrate 50mm × 50mm ~ 510mm × 460mm

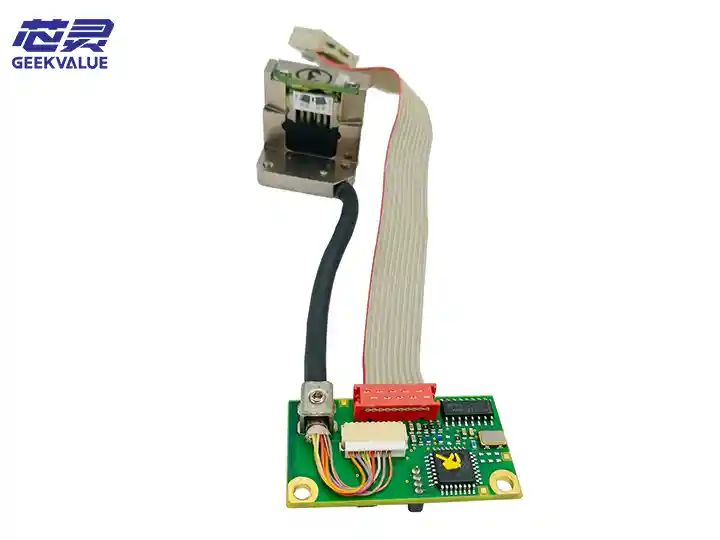

Enkola y’okulaba kkamera ya 5MP HD + amataala agatali ga spectral

Omukutu gwa pulogulaamu SIPLACE Pro / ASM OMS

III. Emirimu emikulu n’ebikozesebwa

1. Okuteeka ku sipiidi n’obutuufu obw’amaanyi

Sipiidi y’enzikiriziganya etuuka ku 60,000 CPH, esaanira ebitundu ebitono n’ebya wakati n’okufulumya obulungi.

±25μm obutuufu, ewagira ebitundu ebituufu nga 01005, 0201, 0.3mm pitch QFN.

2. Dizayini ya modulo

Ensengeka y’omutwe gumu/emitwe mingi ey’okwesalirawo, ekyukakyuka okukola ku bitundu eby’enjawulo (nga resistors, BGA, connectors).

Okukyusa layini mu bwangu ( 3. Enkola ey’amagezi ey’okuliisa Smart Feeder: Laba mu ngeri ey’otoma ekifo omusipi gw’ebintu we guli okukendeeza ku kusuula ebintu. Dual-track feeding (optional): Tewali kuggalawo mu kiseera ky’okukyusa ebintu, okulongoosa mu bulungibwansi. 4. Enkola y’okulaba ey’omulembe 5MP HD camera + multi-angle lighting, okuzuula obulungi ebitundu ebitangaaza n’ebiddugavu. On-the-fly Vision: Okutereeza okw’amaanyi, okukendeeza ku budde bw’okupima. 5. Okufulumya mu ngeri ey’amagezi Sofutiweya wa ASM OMS: Okulongoosa ekkubo ly’okuteeka n’okulongoosa obulungi ebitundu 10%-20%. Obuwagizi bwa Industry 4.0: Okugatta n’enkola ya MES/ERP okutuuka ku kulondoola data. 4. Ensonga eza bulijjo ez’okukozesa Ebyuma ebikozesebwa: motherboard ya ssimu (ebitundu 01005). Ebyuma ebikozesebwa mu mmotoka: ECU control board (QFN, BGA). Okufuga amakolero: Module ya PLC (ekiyungo eky’enjawulo). Ebikozesebwa mu by’obujjanjabi: bboodi ya sensa ey’obulungi obw’amaanyi. 5. Enkola z’okuddaabiriza 1. Okuddaabiriza buli lunaku Buli lunaku: Okwoza entuuyo ne lenzi ya kkamera. Kebera oba ekyuma ekisengejja empewo (vacuum filter) kizibiddwa. Buli wiiki: Siiga ku X/Y axis guide rails ne sikulaapu z’omusulo. Kalibrate omutendera gw’okuliisa. 2. Okupima buli luvannyuma lwa kiseera Buli mwezi: Kola okupima enkola y’okulaba (ng’okozesa olubaawo lw’okupima olwa bulijjo). Kebera puleesa ya Z-axis y’omutwe gw’okuteeka. 3. Olukalala lwa sipeeya ebikulu Nozzle (ey’enjawulo ku 01005/0402). Jenereta ya vacuum. Ggiya/omusipi oguliisa. VI. Ensobi eza bulijjo n’ebirowoozo by’okuddaabiriza 1. Offset y’okussaako Ebiyinza okuvaako ensonga eno: Nozzle ezibidde/yambala → Yoza oba zzaawo nozzle. Okukyama mu kupima okulaba → Ddamu okupima kkamera. Okuteeka PCB si kutuufu → Kebera PIN y'obuyambi. Okugonjoola: Kola Okupima mu Auto Calibration. Kebera ebipimo by'etterekero ly'ebitundu (obugumu, obunene). 2. Omuwendo gw’okusuula ogw’amaanyi Ebiyinza okuvaako ensonga eno: Vacuum etamala (nozzle ezibiddwa/payipu y’empewo ekulukuta) → Kebera vacuum pump (standard>80kPa). Ensobi y’omutendera gw’omuliisa → Ddamu okupima emmere. Okutegeera ebitundu kulemereddwa → Teekateeka ebipimo by’okutaasa. Okugonjoola: Yoza entuuyo era okebere layini ya vacuum. Optimize visual recognition parameters (nga okugattako ekitangaala eky’ebbali). 3. Alaamu y’ekyuma (ensobi mu servo/drive) . Ebiyinza okuvaako ensonga eno: Motor overload → Kebera okusiiga kwa guide rail. Encoder okulemererwa → Ddamu okutandika oba zzaawo layini ya encoder. Amasannyalaze gakyukakyuka → Kebera vvulovumenti ya phase ssatu. Okugonjoola: Kebera koodi y’ensobi (nga E-stop, Axis Error). Nywa mu ngalo X/Y axis okukebera oba ekwatiddwa. 4. Omuliisa talya Ensonga eziyinza okubaawo: Olutambi lusibye → Sika ekintu mu ngalo okuggyawo ekintu ekikwatiddwa. Sensulo ncaafu → Yoza sensa y’amasannyalaze g’ekitangaala. Okukwatagana okubi kw’amasannyalaze → Ddamu ssaako layini ya siginiini. Okugonjoola: Kebera oba ggiya ya feeder ekwatagana. Kikyuseemu ebikozesebwa mu feeder ebyonooneddwa. VII. Okubumbako ASM SIPLACE X2S kyuma kya kuteeka sipiidi ya wakati etali ya ssente nnyingi era ekyukakyuka nga kisaanira ebyetaago by’okufulumya ebitonotono n’ebya wakati n’eby’enjawulo. Enkola yaayo eya modulo, enkola yaayo ey’okuliisa mu ngeri ey’amagezi n’okulaba mu ngeri entuufu bigifuula ekifo ekirungi ennyo mu kukola ebyuma. Ensonga enkulu mu kuddaabiriza: ✔ Okuddaabiriza buli kiseera kiyinza okukendeeza ku bitundu 80% eby’okulemererwa. ✔ Ku bizibu ebizibu, kirungi okutuukirira abayambi ab’ekikugu abatongole aba ASM. Okumanya ebisingawo, nsaba otunule mu SIPLACE X2S Service Manual oba ofune obuwagizi ng'oyita mu ASM remote diagnostic tool.