I-ASM SIPLACE X2S ngumatshini wokubekwa kweemodyuli ophakathi kunye nesantya esiphezulu owasungulwa yi-ASM Assembly Systems (eyayisakuba yiSiemens Electronics Assembly Division). Ibonisa ukuguquguquka, ukuchaneka okuphezulu kunye nokulula kokusetyenziswa, kwaye ifanelekile kwibhetshi encinci kunye nephakathi, iimeko ezahlukeneyo zokuvelisa i-elektroniki, ezifana ne-electronics yabathengi, i-automotive electronics, ulawulo lwamashishini, njl.

Ukuma kwemarike:

✔ Iinkampani ze-EMS ezincinci kunye neziphakathi

✔ Ukuveliswa komxube ophezulu

✔ I-R&D kunye nemveliso yovavanyo lwebhetshi encinci

II. Iimpawu eziphambili kunye neeparitha zobugcisa

Iimpawu ze-X2S zeparamitha

Isantya sokubeka 30,000 - 60,000 CPH (kuxhomekeke kubumbeko)

Ukuchaneka kokubekwa ±25μm @3σ (ixhasa 01005 amacandelo)

Uluhlu lwecandelo 01005 ~ 50mm × 50mm

Umthamo we feeder Ukuya kuthi ga kwi 120 (8mm tape)

Ubungakanani beSubstrate 50mm × 50mm ~ 510mm × 460mm

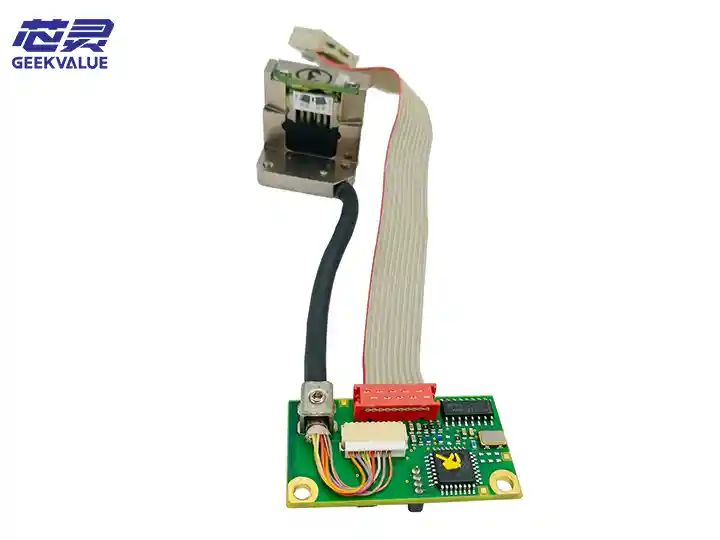

Inkqubo yombono we-5MP ikhamera ye-HD + izibane ezininzi ze-spectral

Iqonga lesoftware SIPLACE Pro / ASM OMS

III. Imisebenzi engundoqo kunye neempawu

1. Ukubekwa kwesantya esiphezulu kunye nokuchaneka okuphezulu

Isantya sethiyori sifikelela kwi-60,000 CPH, ifanelekile kwiibhetshi ezincinci kunye neziphakathi kunye nemveliso esebenzayo.

±25μm ukuchaneka, ixhasa amacandelo echanekileyo ezifana 01005, 0201, 0.3mm pitch QFN.

2. Uyilo lwemodyuli

Ukukhethwa kwentloko enye-intloko / i-multi-head configuration, iguquguqukayo ukujongana namacandelo ahlukeneyo (njengabaxhatshazi, i-BGA, izixhumi).

Ukutshintsha komgca okhawulezayo (<10 imizuzu), ukunciphisa ixesha lokuphumla.

3. Inkqubo yokutya ekrelekrele

I-Smart Feeder: Chonga ngokuzenzekelayo indawo yebhanti yezinto zokunciphisa ukuphosa izinto.

Ukutya okuphindwe kabini (ukhetho): Akukho kuvalwa ngexesha lokutshintsha kwezinto, phucula ukusebenza kakuhle.

4. Inkqubo yombono ophezulu

Ikhamera ye-5MP ye-HD + isibane esine-angle ezininzi, ukuchongwa okuchanekileyo kwezinto ezikhanyayo kunye nezimnyama.

Umbono we-on-the-fly: Ulungiso olunamandla, ukunciphisa ixesha lokulinganisa.

5. Imveliso ehlakaniphile

Isoftware ye-ASM OMS: Lungiselela indlela yokubeka kunye nokuphucula ukusebenza kakuhle nge-10% -20%.

Inkxaso yoShishino 4.0: Ukudityaniswa nenkqubo ye-MES/ERP ukuphumeza ukulandeleka kwedatha.

4. Iimeko zesicelo esiqhelekileyo

I-elektroniki yabathengi: i-motherboard ye-smartphone (i-01005 amacandelo).

I-Automotive electronics: Ibhodi yokulawula ye-ECU (QFN, BGA).

Ulawulo lwemizi-mveliso: Imodyuli yePLC (isidibanisi esinemilo ekhethekileyo).

Izixhobo zonyango: ibhodi yenzwa ephezulu echanekileyo.

5. Iindlela zogcino

1. Ulondolozo lwemihla ngemihla

Yonke imihla:

Coca umbhobho kunye nekhamera yekhamera.

Khangela ukuba isihluzi sevacuum sivaliwe na.

Rhoqo ngeveki:

Lubricate i-X/Y i-axis guide rails kunye ne-lead screws.

Lungiselela inyathelo le feeder.

2. Ulungelelwaniso lwexesha

Ngenyanga:

Yenza ulungelelwaniso lwenkqubo yokubona (usebenzisa ibhodi yokulinganisa esemgangathweni).

Khangela uxinzelelo lwe-Z-axis yentloko yokubeka.

3. Uluhlu lwamalungu angundoqo

Umbhobho (owodwa ku-01005/0402).

Vacuum generator.

Isixhobo sokutyisa/ibhanti.

VI. Iimpazamo eziqhelekileyo kunye neengcamango zokulondoloza

1. Ukunyuka kwe-offset

Unobangela onokwenzeka:

Umlomo uvalekile/unxitywe → Coca okanye buyisela umlomo.

Ukutenxa ulungelelwaniso olubonakalayo → Lungisa kwakhona ikhamera.

Indawo yePCB ayichanekanga → Jonga iPIN yenkxaso.

Isisombululo:

Yenza ulungelelwaniso oluzenzekelayo.

Jonga iiparamitha zethala lecandelo (ukutyeba, ubungakanani).

2. Izinga eliphezulu lokuphosa

Unobangela onokwenzeka:

Isifunxa esingonelanga (umbhobho uvalekile/umbhobho womoya uyavuza) → Jonga impompo yokufunxa (umgangatho>80kPa).

Impazamo yenyathelo lomnikezeli → Lungisa kwakhona isixhasi.

Uqwalaselo lwecandelo aluphumelelanga → Lungisa iiparamitha zokukhanyisa.

Isisombululo:

Coca i-nozzle kwaye ujonge umgca we-vacuum.

Lungiselela iiparamitha zokuqonda okubonakalayo (ezifana nokongeza ukukhanya kwecala).

3. Ialam yomatshini (impazamo ye-servo/drive)

Unobangela onokwenzeka:

Ukugcwala kweemoto → Jonga isikhokelo sokuthanjiswa kukaloliwe.

Ukusilela kweKhowudi → Qalisa kwakhona okanye buyisela umgca we-encoder.

Ubonelelo lwamandla luyaguquguquka → Jonga umbane wamanqanaba amathathu.

Isisombululo:

Jonga ikhowudi yemposiso (efana ne-E-stop, i-Axis Error).

Ngesandla tyhala umgca we-X/Y ukujonga ukuba ixingile.

4. Umondli akondli

Izizathu ezinokwenzeka:

Iteyiphu ixingekile → Tsala ngokwenza into into ebambekayo.

Isivamvo simdaka → Coca inzwa yombane.

Uqhagamshelwano lombane olungalunganga → Phinda uqhagamshele umgca wesignali.

Isisombululo:

Jonga ukuba isixhobo sokutyisa silungelelanisiwe.

Faka endaweni ezonakeleyo izincedisi feeder.

VII. Isishwankathelo

I-ASM SIPLACE X2S iyimatshini yokubeka i-medium-speed-speed-speed ebiza imali eninzi kwaye iguquguquka ilungele ibhetshi encinci kunye nephakathi kunye neemfuno zokuvelisa ezahlukeneyo. Uyilo lwayo lweemodyuli, inkqubo yokondla ekrelekrele kunye nombono ochanekileyo kakhulu iyenza ibe lolona khetho lufanelekileyo kwimveliso yombane.

Amanqaku aphambili ogcino:

✔ Ukugcinwa rhoqo kunokunciphisa i-80% yokusilela.

✔ Ngeengxaki ezinzima, kuyacetyiswa ukuba uqhagamshelane ne-ASM esemthethweni yenkxaso yobugcisa.

Ngolwazi oluthe vetshe, nceda ubhekisele kwi-SIPLACE X2S Service Manual okanye ufumane inkxaso ngesixhobo sokuxilonga esikude se-ASM.