DEK 03IX is an advanced screen printing device produced by DEK (now part of ASM Assembly Systems), designed for the electronics manufacturing industry, especially for high-precision printing applications in surface mount technology (SMT) production lines.

Product Positioning

DEK 03IX is positioned as a mid-to-high-end SMT printing solution, mainly serving:

Consumer electronics manufacturers

Automotive electronics suppliers

Industrial electronics manufacturers

Communication equipment manufacturers

Medical electronic equipment manufacturers

Technical parameters

Basic specifications

Printing area: Maximum PCB size of 510mm × 460mm

Printing speed: Up to 20 seconds/cycle (depending on the complexity of the PCB)

Repeat accuracy: ±12.5μm @ Cpk≥1.0

Alignment accuracy: ±15μm @ Cpk≥1.0

Scraper pressure range: 0-20kg adjustable

Separation speed: 0.1-20mm/s adjustable

Mechanical properties

Frame size compatibility: supports 29"×29" standard screen fram

Z-axis travel: 0-6mm adjustable

θ-axis adjustment: ±5° rotation correction capability

Substrate thickness range: 0.2-6mm

Control system

Adopts advanced VisionAlign™ visual alignment system

Multi-camera high-resolution imaging system

Real-time SPC data collection and analysis function

Support SECS/GEM communication protocol

Core technology and innovative features

1. Intelligent printing technology

Real-time adaptive control system: can automatically adjust printing parameters according to solder paste characteristics

Intelligent pressure control: dynamically adjust scraper pressure to adapt to different pad designs

Automatic screen cleaning system: programmable cleaning frequency and method

2. High-precision visual system

Adopts multi-angle lighting and high-resolution CCD camera

Supports multiple mark point recognition algorithms

Sub-pixel image processing technology

Automatic focus and lighting adjustment function

3. Advanced process control

Closed-loop controlled scraper system

Real-time monitoring of printing quality

Automatic solder paste volume detection function

3D solder paste detection option (additional modules are required)

4. User-friendly design

15-inch color touch screen interface

Graphical programming environment

Formula management system

Remote diagnosis and maintenance function

System architecture

Hardware composition

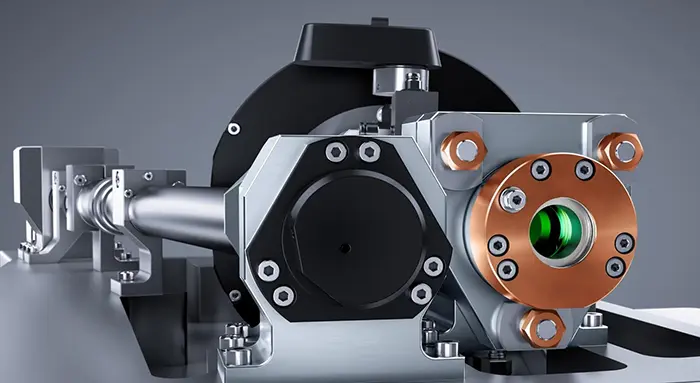

Host frame: high-strength aluminum alloy structure, providing stable support

Print head system: including dual scraper device, pressure sensor and height sensor

Vision system: upper and lower dual camera configuration

Transmission system: high-precision guide rail and belt drive

Stencil fixing system: pneumatic clamping device

Substrate positioning system: programmable support pin and edge clamp

Software system

DEK Instinctiv™ V9 operating system: dedicated software based on Windows platform

Process optimization module: automatic parameter suggestion function

Data analysis tool: real-time SPC chart and trend analysis

Network connection: support factory MES system integration

Application field

Typical application

Ultra-fine pitch printing of 01005 and smaller components

Flip chip Chip) applications

Wafer-level packaging (WLCSP)

High-density interconnect (HDI) boards

Flexible circuit board (FPC) printing

Special process capabilities

Mixed technology printing (solder paste and conductive glue)

Step stencil printing

Double-sided printing process

High viscosity material printing (such as bottom filler)

Performance advantages

Production efficiency

Quick line change time (<5 minutes)

High first pass yield (FPY)

High continuous production stability

Support non-stop stencil cleaning

Quality assurance

High printing consistency

Low defect rate

Solder paste Excellent molding quality

Automatic process compensation function

Cost-effective

Low material waste

Low maintenance cost

High energy efficiency

Significant total cost of ownership (TCO) advantage

Optional items

Hardware options

3D solder paste inspection system: real-time volume measurement

Dual track transmission system: support continuous production

Nitrogen protection device: for special processes

High viscosity material kit: for special slurries

Software options

Advanced data analysis package: in-depth process analysis

Remote monitoring module: real-time equipment status view

Intelligent maintenance system: predictive maintenance function

Maintenance and Service

Daily Maintenance

Recommended Daily Cleaning Items

Weekly Checklist

Monthly Maintenance Plan

Technical Support

Global Service Network

24/7 Technical Support Hotline

Online Knowledge Base and Troubleshooting Guide

Regular Software Updates

Market Positioning and Competitive Analysis

Target Market

Medium to High Volume SMT Production Lines

Electronics Manufacturers with High Mix Production

Fields with Strict Printing Quality Requirements

Comparison with Major Competitors

Compared with similar equipment such as MPM Ultraprint 3000, Ekra X5, DEK 03IX has advantages in the following aspects:

Friendlier user interface

More flexible configuration options

Lower maintenance requirements

Better cost-effectiveness

Development trends and future upgrades

Technology evolution direction

AI-assisted process optimization

Augmented reality (AR) maintenance assistance

Deeper integration of Industry 4.0

Environmentally friendly and energy-saving design improvements

Upgrade path

Hardware modular design for easy upgrade

Good software backward compatibility

Expandable I/O interface

User evaluation and industry recognition

Typical user feedback

"Printing stability exceeds expectations"

"Line change time is greatly reduced"

"Excellent adaptability to difficult PCBs"

"Intuitive and easy-to-use operation interface"

Awards and certifications

Won multiple industry innovation awards

Complies with safety certifications such as CE and UL

Meets IPC standard requirements

Summary

DEK 03IX represents the advanced level of current SMT printing technology, and provides reliable printing solutions for electronic manufacturing through its high precision, intelligent and user-friendly design. Whether it is mass production or high-mix environment, 03IX can provide excellent performance to help users improve quality, reduce costs and improve efficiency.