1. Isishwankathelo

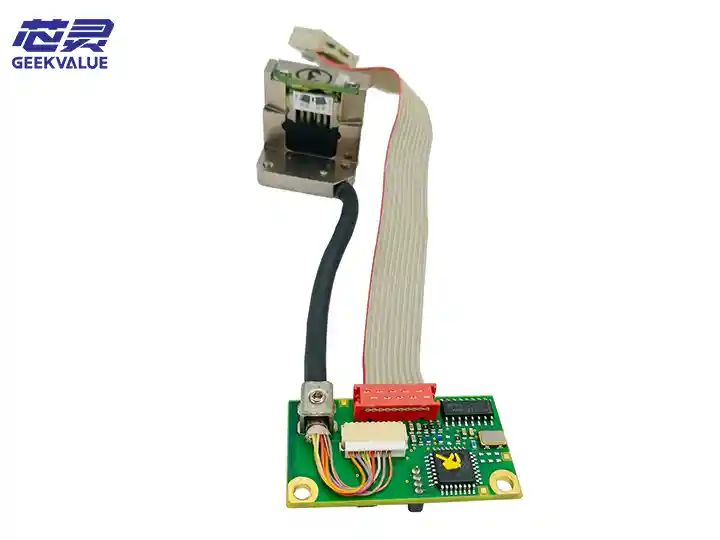

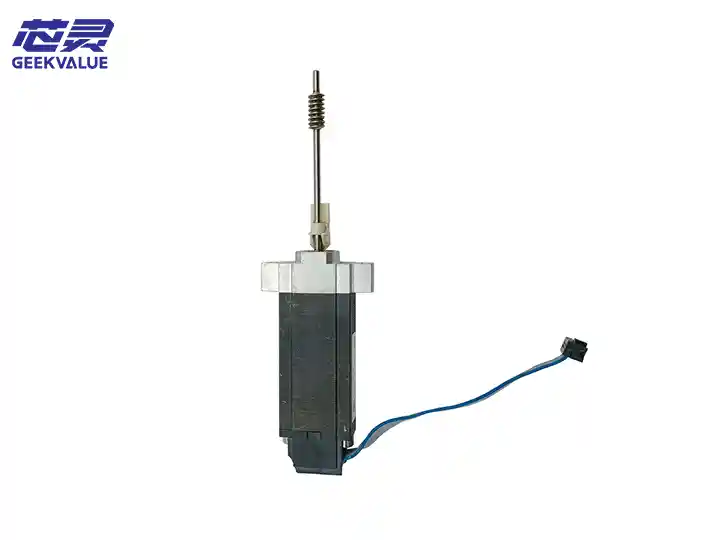

Umzekelo: 03106620

Izixhobo ezisebenzayo: I-ASM SIPLACE CP20P intloko yokubeka (ehlala isetyenziswa kwi-SIPLACE X yochungechunge kunye noomatshini bokubekwa kwe-D)

Umsebenzi ongundoqo: Ngexesha lokubekwa kwesantya esiphezulu, izixhobo ze-elektroniki zicholwa ngokuzinzileyo kwaye zibekwe ngomgaqo we-vacuum adsorption ukuqinisekisa ukuchaneka kokubeka kunye nokusebenza kakuhle.

2. Imisebenzi engundoqo

I-adsorption ye-vacuum: uxinzelelo olubi lwenziwa ukwenzela ukuba umlomo wombhobho ukwazi ukubhengeza izinto (ezifana ne-resistors, capacitors, ICs, njl.).

Impendulo ekhawulezayo: isekela ukusebenza kwesantya esiphezulu somatshini wokubeka (njengaphezulu kwe-30,000 CPH), kunye nesenzo sokuthatha kunye nendawo sigqitywe kwi-milliseconds.

Uxinzelelo olunokulungiswa: ukulungelelanisa kumacandelo obungakanani obuhlukeneyo kunye nobunzima (njenge-0201 amacandelo amancinci okanye i-BGA enkulu).

Ulungelelwaniso lwemilomo emininzi: ezinye izilungiso zixhasa ulawulo lwe-vacuum oluzimeleyo lwemilomo emininzi ukuphucula ukuguquguquka kokubeka.

3. Umgaqo wokusebenza

3.1 Ngokusekelwe kuMgaqo weVenturi

Igalelo lomoya oxinanisiweyo: igesi ephezulu yoxinzelelo (0.4 ~ 0.6 MPa) ingena kwi-generator ukusuka kwi-air inlet.

Isantya esiphezulu somoya sivelisa uxinzelelo olubi: Xa i-airflow idlula kumjelo omncinci, isantya sinyuka, senze indawo ephantsi yoxinzelelo kwi-vacuum room, kwaye icandelo libhengezwa ngombhobho.

Ukukhutshwa kwecandelo: Ivalve ye-solenoid itshintsha indlela yokuhamba komoya, inqumle ivacuum okanye ivuthele umoya ngokufutshane, ukuze inxalenye yohlulwe emlonyeni kwaye ifakwe ngokuchanekileyo.

3.2 Ukuhamba komsebenzi

umbhalo

Umoya oxinisiweyo → Igumbi leVenturi → I-adsorption yeVacuum → Choko zixhobo → Hambisa kwiPCB → Khupha izixhobo → Gqibezela ukunyuswa

4. Iimpazamo eziqhelekileyo kunye nezisombululo

4.1 Isitshixo esinganelanga (indawo engazinzanga yokulanda okanye ukulahla)

Izizathu ezinokwenzeka:

Ukungonelanga uxinzelelo lomoya (ngaphantsi kwe-0.4 MPa).

I-nozzle ivaliwe okanye igugile (i-aperture deformation).

Ukuvuza komgca wevacuum (ukuguga kweringi yokutywina okanye amalungu axengaxengayo).

I-vacuum generator ingcolisekile ngaphakathi (uthuli, intsalela ye-solder paste).

Isisombululo:

Jonga uxinzelelo lomthombo womoya kwaye ulungelelanise malunga ne-0.5 MPa.

Coca okanye ubuyisele umlomo wombhobho (qinisekisa ukuba akukho nto ivalekileyo).

Jonga ukuqina komgca womoya kwaye ubuyisele i-O-ring eyonakalisiweyo okanye umbhobho womoya.

Hlukanisa i-vacuum generator kwaye uhlambulule ngaphakathi ngotywala obungenamanzi.

4.2 Ivacuum ayinakuvalwa (icandelo alikhululwa)

Izizathu ezinokwenzeka:

Ukusilela kwevalve ye-Solenoid (ikhoyili etshileyo okanye undoqo wevalve uxinge).

Isiginali yokulawula engaqhelekanga (PLC okanye I/O ingxaki yemodyuli).

Umzimba wevalvu wangaphakathi wejenereyitha yofukula wonakele.

Isisombululo:

Vavanya ivalve ye-solenoid ekuvuleni nasekuvaleni kwaye ubuyisele umzimba wevalvu engalunganga.

Khangela ukuba isignali yolawulo yomatshini wokubeka iphuma ngokuqhelekileyo.

Ukuba umzimba wevalve yangaphakathi wonakalisiwe, yonke ijenereyitha yokufunxa (03106620) kufuneka itshintshwe.

4.3 Ingxolo engaqhelekanga (impempe okanye ukungcangcazela)

Izizathu ezinokwenzeka:

Isifihli siyasilela okanye siyawa.

Uxinzelelo lokuhamba komoya luphezulu kakhulu (ngaphezu kwe-0.6 MPa).

Ukunxiba kwangaphakathi kwe-vacuum generator (i-Venturi tube ikhubazekile).

Isisombululo:

Khangela ukuba i-muffler ifakwe endaweni kwaye uyibuyisele ukuba kuyimfuneko.

Lungisa i-valve yokunciphisa uxinzelelo ukuze uzinzise uxinzelelo lomoya kwi-0.4 ~ 0.6 MPa.

Ukuba isakhiwo sangaphakathi sonakalisiwe, i-vacuum generator kufuneka itshintshwe.

5. Iindlela zogcino

5.1 Ulondolozo lwemihla ngemihla

Ukucoca umlomo wokufunxa kunye nombhobho wokufunxa:

Sula umbhobho wokufunxa ngelaphu elingenathuli elifakwe kwi-anhydrous alcohol yonke imihla ukunqanda intlama ye-solder okanye intsalela ye-flux.

Coca umbhobho wokufunxa ngompu womoya ukunqanda ukufumba kothuli.

Jonga ukuzinza koxinzelelo lomoya:

Qinisekisa ukuba uxinzelelo lomthombo womoya luphakathi koluhlu lwe-0.5±0.1 MPa.

Ukulinganisa rhoqo usebenzisa i-barometer.

5.2 Ukugcinwa rhoqo (kucetyiswa kanye kwiinyanga ezi-3)

Susa i-vacuum generator:

Cima umthombo womoya, ukhuphe umbhobho womoya kunye nojongano lombane.

Susa izikrufu zokulungisa kwaye ususe ngokucophelela i-generator.

Ukucoca kwangaphakathi:

Coca igumbi le-Venturi nge-ultrasonic cleaner (okanye utywala + ibrashi ethambileyo).

Jonga ukuba i-O-ring iyaguga kwaye uyibuyisele ukuba kukho imfuneko (jonga kwi-ASM part number manual).

Faka kwakhona kwaye uvavanye:

Qhuba inkqubo yohlengahlengiso lwevacuum emva kofakelo (jonga kwi-SIPLACE isikhokelo sokusebenza sesoftware).

Vavanya i-adsorption kunye nokukhululwa ngento eqhelekileyo ukuze ubone ukuba iqhelekile na.

5.3 Iingcebiso zokutshintshwa kwezixhobo ezingasetyenziswanga

Kucetyiswa ukuba iinxalenye zokuqala ezisecaleni: ASM 03106620 (ukuqinisekisa ukuhambelana).

Ukutshintshwa komntu wesithathu: Qinisekisa ukuba ubungakanani bojongano, idigri yevacuum kunye nexesha lokuphendula lihambelana.

6. Iiparamitha zobugcisa (ireferensi)

Ukucaciswa kweParameter

Uxinzelelo lomoya osebenzayo 0.4 ~ 0.6 MPa

Isidanga seVacuum -60 kPa ~ -80 kPa

Ixesha lokuphendula ≤10 ms

Uhlobo lwe-Interface uhlobo lwe-G1/8 intshi yentambo okanye isinxibelelanisi esikhawulezayo

Ubushushu be-Ambient 5~40°C

Ubomi benkonzo Malunga nemijikelo engama-500,000 (kuxhomekeke kulondolozo)

7. Izilumkiso

Musa ukusebenzisa umoya oxinzelelweyo oqukethe ioli okanye umswakama, ngaphandle koko kuya kubangela ukubola kwangaphakathi okanye ukungcoliswa kwecandelo.

Xa unyuswa amacandelo amancinci (afana ne-01005), idigri ye-vacuum kufuneka incitshiswe ukukhusela amacandelo ukuba angabhabha.

Xa umatshini uvaliwe ixesha elide, indlela yomoya kufuneka iphelelwe kwaye i-interface kufuneka ivalwe ukukhusela uthuli ukuba lungene.