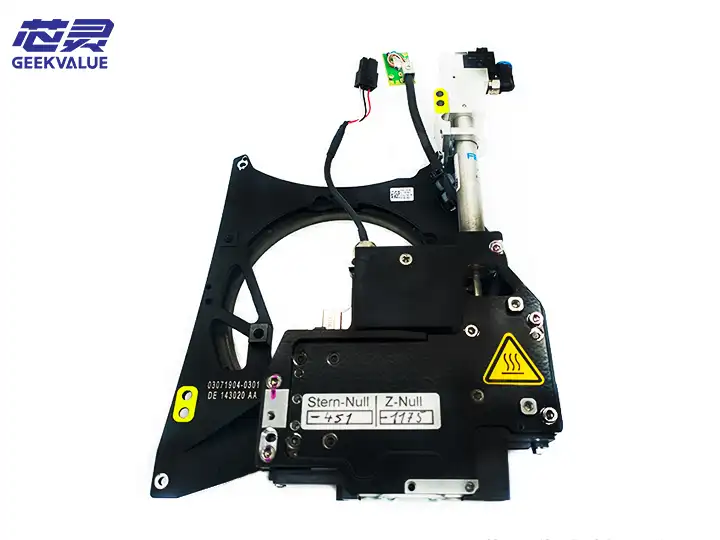

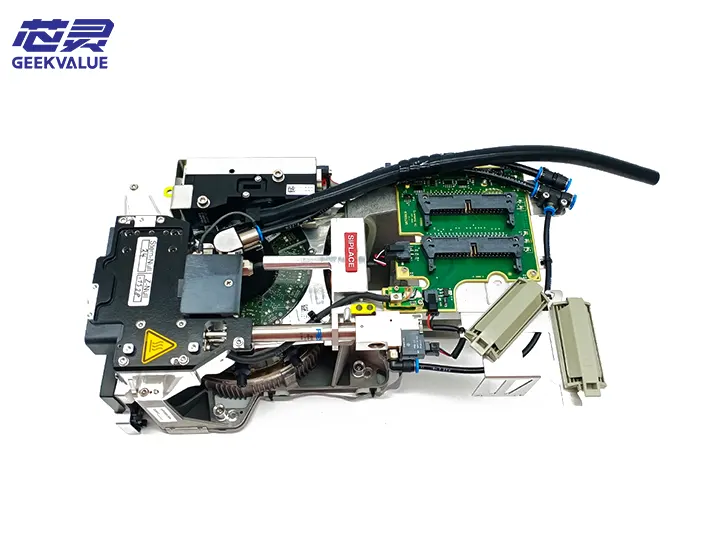

ASM 03039099 slider waa qaybta gudbinta xudunta u ah CPP (Processor Meelaynta Qaybaha) madaxa meelaynta. Waa qayb muhiim ah oo ka mid ah nidaamka dhaqdhaqaaqa toosan ee saxda ah oo si toos ah u saameeya:

Xaqiijinta meelaynta (± 25μm)

Xawaaraha orodka (ilaa 150mm/ms dardargelinta)

Nolosha qalabka (nakhshad nolosha ≥ 5 milyan wareegyada)

II. Tilmaamaha Muhiimka ah

Halbeegyada Farsamada Mashruuca Qodobbada Farsamo ee Farsamada

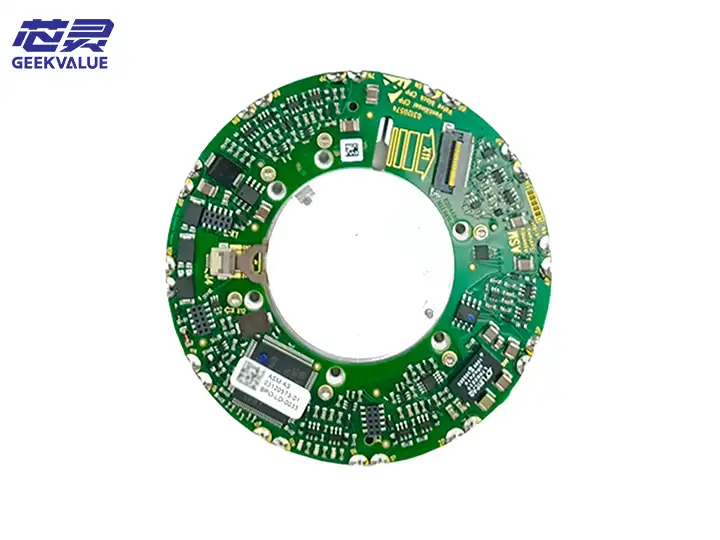

Qaab-dhismeedka Nooca Afar- Safka ah ee Kubadda Tusaha Tooska ah ee La Hagajin karo (Fasalka P0-P2)

Heerka Dhererka Hagaha 320mm (la beddeli karo ± 50mm) Naqshadaynta bannaan waxay yaraynaysaa miisaanka 30%

Saxnimada Fasalka C3 Fasalka (± 5μm/300mm) 40% ka sarreeya heerka caadiga ah ee C5

Awoodda Xamuulka Radial 50kg/Axial 25kg Cunsurka Culayska Dhaqdhaqaaqa 1.5

Habka Sifeynta Module Is-saliid (Kaydinta Saliida ≥ 5 Sano) Naqshad bilaa dayactir ah

Walxaha Sidda Birta GCr15+Oxidation-ka Daaweynta Adag HRC60±2

III. Shaqada iyo mabda'a shaqada

Shaqada asaasiga ah

Ku guulaysta dhaq-dhaqaaq toosan oo toosan oo xawaarihiisu sarreeyo oo madaxa meelaynta ah ee jihada X/Y

20G dardargelinta naxdinta leh ee habka wax-ku-qaadista

Tirtiridda caddaynta gadaal u soo shubista (≤2μm)

Nidaamka iskaashiga

Dhaqdhaqaaqa 3D waxaa lagu dhameeyay isku xirka DP motor (sida 03050314)

Udub dhexaadinta duulimaadka waxaa lagu xaqiijin karaa nidaamka aragga

IV. Farsamaynta farsamada

Nakhshad raadraac oo la xoojiyey

Xagasha xidhiidhka 45° waxa ay wanaajisaa qaybinta culayska

Dulqaadka dhexroorka kubbadda ± 0.5μm

Farsamada boodhka celinaysa

Nidaam saddex-heer ah oo shaabadeynta ah ( xoqida caag + labyrinth + shaabad birlab ah)

ISO 14644-1 Shahaadada heerka 5

Deganaanshaha kulaylka

Kordhinta balaadhinta kulaylka 11.5 × 10⁻⁶ / ℃ (ku habboon jir aluminium alloy ah)

Heerkulka kor u kaca ΔT≤15K@load buuxa

V. Habka fashilka caadiga ah iyo daaweynta

Dhacdadii fashilantay ee Xididku sababa Xalka

Dhaqdhaqaaq aan caadi ahayn Xirashada kubbadda/sifeyn liidata 1. Beddel kubbadda (φ3.175mm G10 darajo)

2. Ku dar Molykote PG-641 dufan

Meesha leexsanaan Horudhac daalka gu'ga Hagaaji lowska horudhaca ah (qulqulka 1.2N·m±0.1)

Slider ayaa ku dheggan Walax shisheeye ayaa soo gasha jidka 1. Kala saar oo nadiifi

2. Beddel kulanka shaabbada (ASM P/N: 03039100)

Gariirku waxa uu dhaafey heerka caadiga ah Rakibaadda oogada Rakibaadda ayaa dhaaftay dulqaadka Ku celi dusha korka ah (loo baahan ≤0.01mm/m)

VI. Tilmaamaha dayactirka iyo daryeelka

Kormeer maalinle ah

Maalin kasta:

Ausculte qaylada orodka (caadi ≤55dB)

Hubi daacadnimada xadhigga xidhitaanka

Todobaadle:

Cabbir heerkulka raadraaca (heerkulka deegaanka + ΔT ≤25℃)

Dayactirka xirfadeed

6dii biloodba mar:

Nadiifi jidka oo dib u saliid (qadarka dufanka 0.3g/100mm)

Hubi xirashada kubbadda (farqiga dhexroorka ≥0.002mm wuxuu u baahan yahay in la beddelo)

3dii sanoba mar:

Si buuxda u beddel kooxda kubbadda (NSK kubbadda asalka ah ayaa lagula talinayaa)

VII. Qodobbada farsamada ee kala dirida iyo isu-ururinta

Habka kala furfurida

Isticmaal xajin gaar ah si aad u hagaajisid slider-ka (si aad uga hortagto sii-deynta cadaadiska ka horreeya dadka dhaawaca ah)

U soo daa siday u kala horreeyaan:

Daboolka dhamaadka (M4×8, 4 meelood)

Raad raac boolalka hagaajinta (M6×12, 8 meelood)

Tilmaamaha rakibidda

Shuruudaha nadaafadda dusha sare ee fuulista:

Roughness Ra≤0.8μm

Baaxadda≤0.005mm

Isku hagaajinta cadaadiska ka hor waxay u baahan tahay Torque + barokacinta habka laba-koontorool

VIII. Hagaajinta iyo xalalka kale

Nooca cusboonaysiinta waxqabadka (03039099-PRO)

Kubbada dhoobada (cimrigu wuxuu kordhay 3 jeer)

Dareemaha heerkulka isku dhafan

Beddelka dhaqaale

Qaybaha dib loo warshadeeyay (ASM shahaado, 40% qiimo hoose)

Halbeegyada hore u-qaadista waxay u baahan yihiin in la hagaajiyo

IX. Horumarka tignoolajiyada

la socodka caqliga

Jiilka soo socda ayaa isku dari doona dareemayaasha gariir (ISO 10816 standard)

Codsiga alaabta cusub

Silicon nitride dhoobada track (marxaladda tijaabada)

X. Talooyinka isticmaalka

Shuruudaha deegaanka

Heerkulka 15-35 ℃, huurka 30-70% RH

Nadaafadda ≥ ISO Class 7

Istaraatiijiyada qaybaha qalabka

Talada khadka wax soo saarka ee muhiimka ah 1:5 saamiga agabka agabka

Alaabta waa in ay ku jiraan:

Kubbada dhejiska (03039101)

Xirmada shaabadda (03039100)