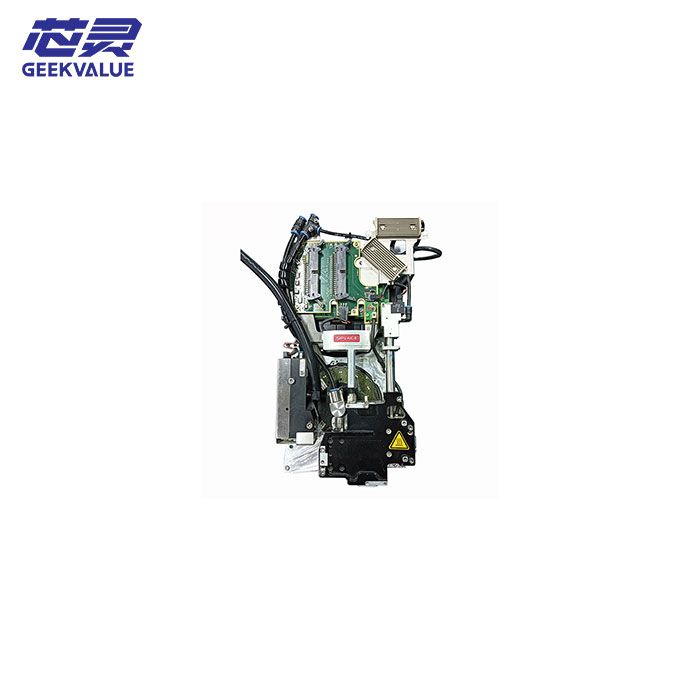

ASM 03039099 slider is the core transmission component of CPP (Component Placement Processor) placement head. It is a key component of high-precision linear motion system and directly affects:

Placing accuracy (±25μm)

Running speed (up to 150mm/ms acceleration)

Equipment life (design life ≥ 5 million cycles)

II. Core Specifications

Project Technical Parameters Technical Highlights

Structural Type Four-row Ball Linear Guide Adjustable Preload (P0-P2 Grade)

Guide Length Standard 320mm (Customizable ±50mm) Hollow design reduces weight by 30%

Accuracy Grade C3 Grade (±5μm/300mm) 40% higher than conventional C5 Grade

Load Capacity Radial 50kg/Axial 25kg Dynamic Load Factor 1.5

Lubrication Method Self-lubricating Module (Oil Storage ≥ 5 Years) Maintenance-free Design

Material Bearing Steel GCr15+Oxidation Treatment Hardness HRC60±2

III. Function and working principle

Core function

Achieve high-speed and precise linear motion of the placement head in X/Y direction

20G acceleration shock of the nozzle bearing mechanism

Eliminate reverse clearance by preloading (≤2μm)

Cooperative system

3D motion is completed by linkage with DP motor (such as 03050314)

Flying centering is realized with the vision system

IV. Mechanical design highlights

Enhanced track design

45° contact angle optimizes load distribution

Ball diameter tolerance ±0.5μm

Dustproof technology

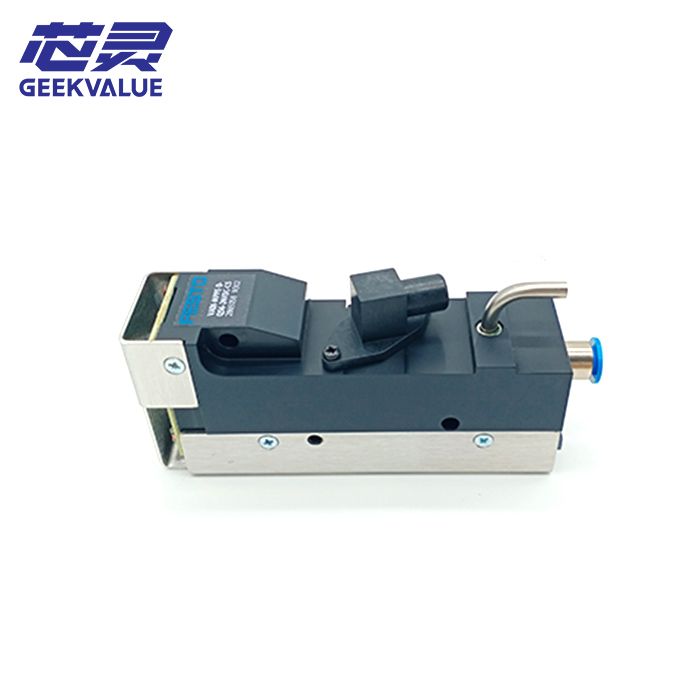

Three-level sealing system (rubber scraper + labyrinth + magnetic seal)

ISO 14644-1 Class 5 certification

Thermal stability

Thermal expansion coefficient 11.5×10⁻⁶/℃ (matching with aluminum alloy frame)

Temperature rise ΔT≤15K@full load

V. Typical failure mode and treatment

Failure phenomenon Root cause Solution

Abnormal movement Ball wear/poor lubrication 1. Replace the ball (φ3.175mm G10 grade)

2. Add Molykote PG-641 grease

Position drift Preload spring fatigue Adjust the preload nut (torque 1.2N·m±0.1)

Slider stuck Foreign matter intrudes into the track 1. Disassemble and clean

2. Replace the seal assembly (ASM P/N: 03039100)

Vibration exceeds the standard Installation surface flatness exceeds tolerance Regrind the mounting surface (required ≤0.01mm/m)

VI. Maintenance and care specifications

Daily inspection

Daily:

Auscultate the running noise (normal ≤55dB)

Check the integrity of the sealing strip

Weekly:

Measure the track temperature (ambient temperature + ΔT ≤25℃)

Professional maintenance

Every 6 months:

Clean the track and relubricate (grease amount 0.3g/100mm)

Check the ball wear (diameter difference ≥0.002mm needs to be replaced)

Every 3 years:

Fully replace the ball group (NSK original ball is recommended)

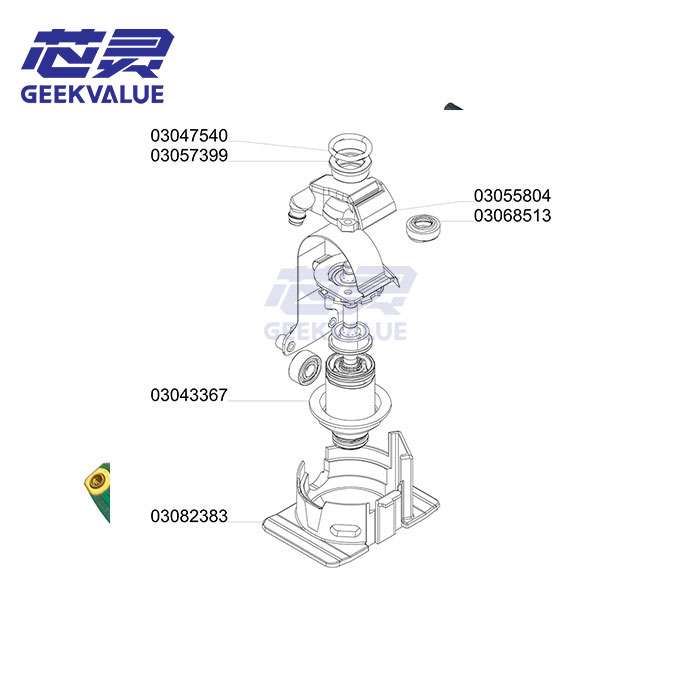

VII. Disassembly and assembly technical points

Disassembly process

Use a special clamp to fix the slider (to prevent pre-pressure release from injuring people)

Release in order:

End cover screws (M4×8, 4 places)

Track fixing bolts (M6×12, 8 places)

Installation specifications

Mounting surface cleanliness requirements:

Roughness Ra≤0.8μm

Flatness≤0.005mm

Pre-pressure adjustment requires Torque + displacement dual control method

VIII. Upgrade and alternative solutions

Performance upgrade version (03039099-PRO)

Ceramic ball (lifespan increased by 3 times)

Integrated temperature sensor

Economical alternative

Remanufactured parts (ASM certified, 40% lower price)

Preload parameters need to be adjusted

IX. Technology development trend

Intelligent monitoring

The next generation will integrate vibration sensors (ISO 10816 standard)

New material application

Silicon nitride ceramic track (test phase)

X. Usage recommendations

Environmental requirements

Temperature 15-35℃, humidity 30-70%RH

Cleanliness ≥ ISO Class 7

Spare parts strategy

Key production line recommendation 1:5 spare parts ratio

Inventory should include:

Ball set (03039101)

Seal kit (03039100)