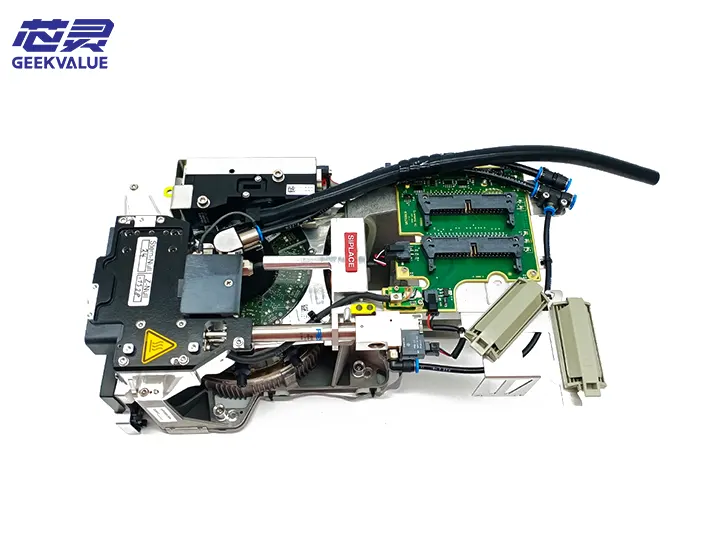

I-ASM 03039099 isilayidi yinxalenye yokuhanjiswa kwe-CPP (i-Component Placement Processor) intloko yokubeka. Liyinxalenye ephambili yenkqubo yentshukumo echanekileyo echanekileyo kwaye ichaphazela ngokuthe ngqo:

Ukubeka ukuchaneka (±25μm)

Isantya sokubaleka (ukuya kuthi ga kwi-150mm/ms yokunyusa)

Ubomi bezixhobo (ubomi boyilo ≥ imijikelo yezigidi ezi-5)

II. Iimpawu eziphambili

IiParameters zeProjekthi yobuGcisa Amanqaku aphezulu

Uhlobo Lwesakhiwo esineMiqolo emine yeBhola yesiKhokelo esiLungiselelayo ukuLayishwa kwangaphambili (iBanga le-P0-P2)

Ubude beSikhokelo soMgangatho oyi-320mm (Okunokwenzeka ±50mm) Uyilo olungenanto lunciphisa ubunzima ngama-30%

Ukuchaneka kweBakala C3 kwiBanga (±5μm/300mm) ngama-40% aphezulu kunoHlelo lwesiqhelo lweC5

Umthamo womthwalo weRadial 50kg/Axial 25kg Dynamic Load Factor 1.5

Indlela yokuthambisa iModyuli yokuSelf-lubricating (UGcino lwe-oyile ≥ iminyaka emi-5) Uyilo olungenaMafa

IMaterial Bearing Steel GCr15+Oxidation Treatment Ukuqina HRC60±2

III. Umsebenzi kunye nomgaqo wokusebenza

Umsebenzi ongundoqo

Ukufezekisa isantya esiphezulu kunye nesinyanzelo esichanekileyo somgca wentloko yokubeka kwi-X / Y indlela

I-20G yokukhawuleza umothuko wesixhobo sokuthwala umlomo

Susa umva umva ngokulayishwa kwangaphambili (≤2μm)

Inkqubo yentsebenziswano

Isindululo se-3D sigqitywe ngonxibelelwano ne-DP motor (efana ne-03050314)

I-Flying centering ifezekiswa kunye nenkqubo yombono

IV. Iimbalasane zoyilo lomatshini

Uyilo oluphuculweyo lwengoma

I-45 ° i-engile yoqhagamshelwano ilungisa ukuhanjiswa komthwalo

Unyamezelo lwedayamitha yebhola ± 0.5μm

Itekhnoloji yothuli

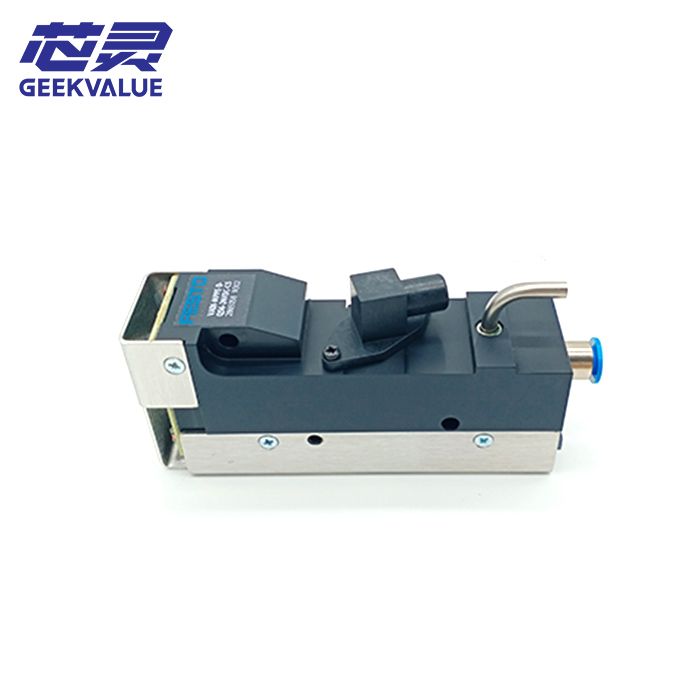

Inkqubo yokutywina enemigangatho emithathu (irabha iskrayi + ilabyrinth + isitywina somagnetic)

Isiqinisekiso se-ISO 14644-1 sodidi lwesi-5

Ukuzinza kwe-Thermal

I-Thermal i-coefficient yokwandisa 11.5×10⁻⁶/℃ (ehambelana nesakhelo se-aluminium alloy)

Ukunyuka kobushushu ΔT≤15K@umthwalo opheleleyo

V. Indlela yokungaphumeleli eqhelekileyo kunye nonyango

Ukusilela isenzeko Ingcambu imbangela Isisombululo

Intshukumo engaqhelekanga Ukunxiba kwebhola/ukuthambisa kakubi 1. Buyisela ibhola endaweni yayo (φ3.175mm ibakala le-G10)

2. Yongeza igrisi ye-Molykote PG-641

Indawo yokukhukuliseka Layisha kwangaphambili ukudinwa kwentwasahlobo Lungisa i-nati yokulayishwa kwangaphambili (torque 1.2N·m±0.1)

Isilayidi sibambekile Umba wangaphandle ungenelela kumzila 1. Uqhawule kwaye ucoceke

2. Faka endaweni yendibano yetywina (ASM P/N: 03039100)

Ukungcangcazela kodlula umgangatho Ukuhlohla umphezulu wokuthe tyaba ukodlula ukunyamezela Phinda ugaye umphezulu onyukayo (ofunekayo ≤0.01mm/m)

VI. Ugcino kunye neenkcukacha zokhathalelo

Ukuhlolwa kwemihla ngemihla

Yonke imihla:

Yandisa ingxolo ebalekayo (eqhelekileyo ≤55dB)

Jonga imfezeko yomgca wokutywina

Rhoqo ngeveki:

Ukulinganisa ubushushu bomzila (ubushushu obuphakathi + ΔT ≤25℃)

Ulondolozo lobungcali

Rhoqo kwiinyanga ezi-6:

Coca umkhondo kwaye uphinde ugaywe (isixa segrisi 0.3g/100mm)

Jonga ukunxiba kwebhola (umahluko wedayamitha ≥0.002mm ifuna ukutshintshwa)

Rhoqo kwiminyaka emi-3:

Libuyisele ngokupheleleyo iqela lebhola (ibhola ye-NSK yoqobo iyacetyiswa)

VII. Amanqaku obugcisa bokuqhaqha kunye nendibano

Inkqubo ye-Disassembly

Sebenzisa i-clamp ekhethekileyo ukulungisa isilayidi (ukuthintela ukukhululwa kwangaphambili koxinzelelo ekwenzakaleni abantu)

Khupha ngolandelelwano:

Izikrufu zesigqubuthelo sokuphela (M4×8, iindawo ezi-4)

Iibholithi zokulungisa umkhondo (M6×12, iindawo eziyi-8)

Iinkcukacha zofakelo

Iimfuno zokunyuka kococeko kumphezulu:

Uburhabaxa Ra≤0.8μm

Umcaba≤0.005mm

Uhlengahlengiso lwangaphambili loxinzelelo lufuna iTorque + ukufuduswa kwendlela yolawulo kabini

VIII. Uphuculo kunye nezinye izisombululo

Inguqulelo yokuphucula ukusebenza (03039099-PRO)

Ibhola yeCeramic (ubomi bunyuswe ngamaxesha ama-3)

Inzwa yobushushu edibeneyo

Enye indlela yezoqoqosho

Iindawo ezenziwe ngokutsha (eziqinisekisiweyo ze-ASM, ixabiso eliphantsi ngama-40%)

Iiparamitha zokulayisha kwangaphambili kufuneka zilungiswe

IX. Umkhwa wophuhliso lwetekhnoloji

Ukubeka iliso okukrelekrele

Isizukulwana esilandelayo siya kudibanisa iinzwa zokungcangcazela (ISO 10816 standard)

Ukusetyenziswa kwezinto ezintsha

Ingoma ye-Silicon nitride ceramic (isigaba sovavanyo)

X. Iingcebiso zokusetyenziswa

Iimfuno zokusingqongileyo

Ubushushu 15-35℃, ukufuma 30-70%RH

Ucoceko ≥ ISO Class 7

Isicwangciso sezixhobo ezisetyenzisiweyo

Isiphakamiso somgca wemveliso engundoqo 1: umlinganiselo we-spare parts ratio

Uluhlu kufuneka lubandakanye:

Iseti yebhola (03039101)

Ikhithi yotywino (03039100)