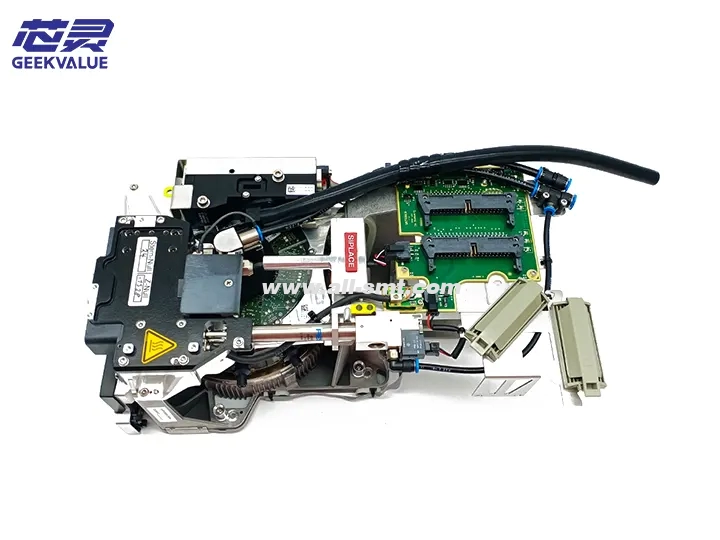

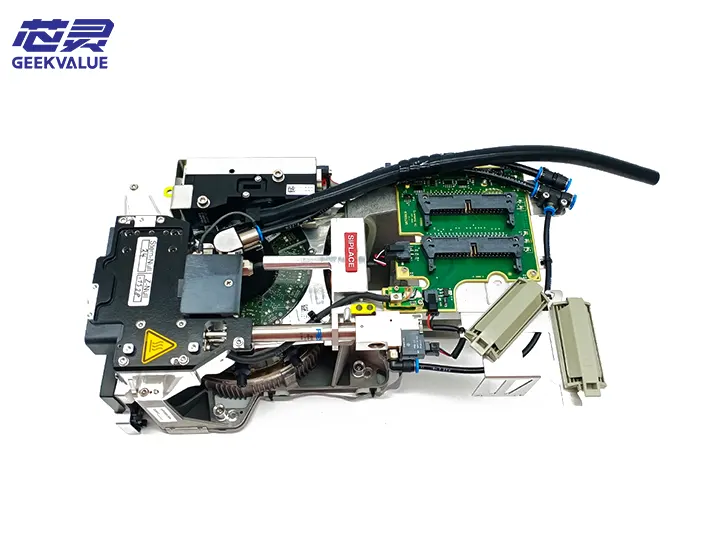

I-CPP (iNtloko yokubeka iCandelo) intloko yomsebenzi iyona nxalenye ephambili yomatshini wokubeka i-ASM, uxanduva lokuthabatha amacandelo kwi-feeder kunye nokubeka ngokuchanekileyo kwibhodi ye-PCB. Intloko yomsebenzi we-CPP ye-ASM (ngoku ye-Siemens Electronic Assembly Systems Division) inandipha udumo oluphezulu kwishishini le-SMT ngokuchaneka kwayo, isantya esiphezulu kunye nokuthembeka okuphezulu.

2. Ukwakhiwa kwesakhiwo

1. Ubume bomatshini

Inkqubo ye-Spindle: ibandakanya i-servo motor, i-high-precision ball screw kunye nesikhokelo somgca

Intonga yombhobho: intonga yokufakela umbhobho endaweni, ngokuqhelekileyo inezikhululo ezili-12 okanye ezili-16

Inkqubo yokucoca: iquka i-vacuum generator, i-vacuum sensor kunye neshaneli yokucoca

Inkqubo yokubeka iziko: inkqubo yokubonwayo kunye ne-mechanical centering claw yecandelo le-centering

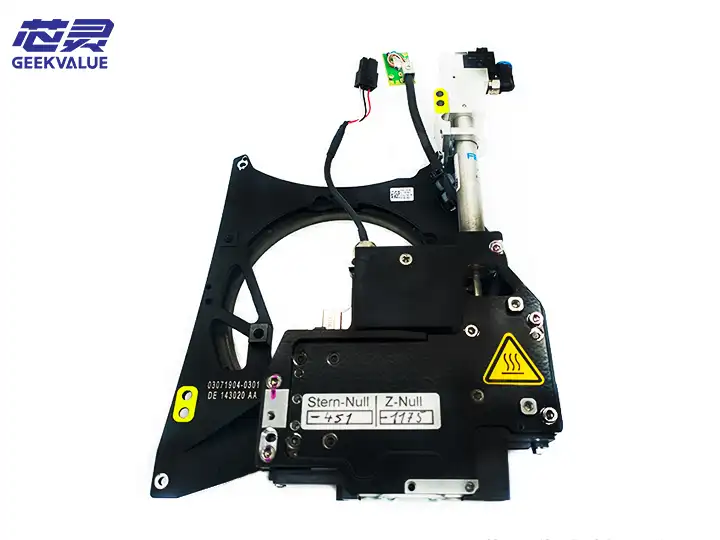

I-Z-axis drive: i-servo okanye inkqubo ye-pneumatic yokulawula ukuphakama kokubeka

θ-ukujikeleza kwe-axis: i-stepper okanye i-servo motor yecandelo lokujikeleza kwe-angle

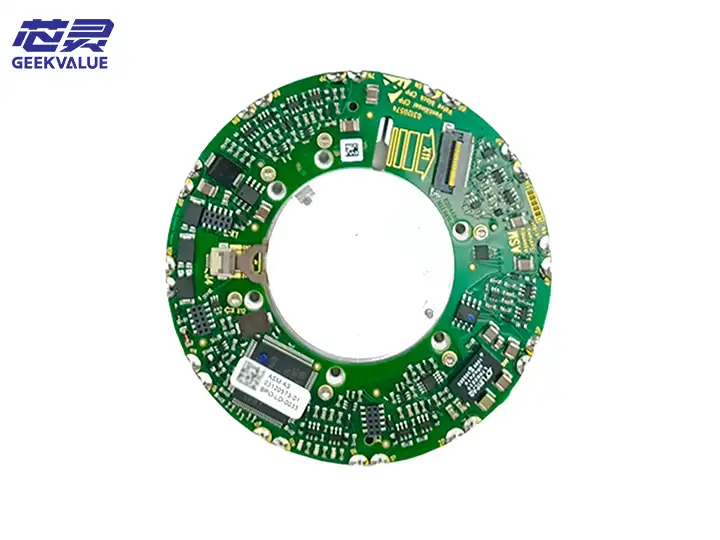

2. Inkqubo ye-elektroniki

Inkqubo ye-Encoder: i-high-resolution encoder yokubekwa okuchanekileyo

Inkqubo yoluvo:

Isivamvo sevacuum

Isivamvo sobude

Uluvo lwendawo

Isivamvo sobushushu

Ibhodi yokulawula: ibhodi yesekethe yolawulo oluzinikeleyo

3. Inkqubo encedisayo

Isixhobo sokubuyisela umbhobho: isixhobo esizenzekelayo okanye esizenzekelayo sokubuyisela umbhobho

Inkqubo yokucoca: isixhobo sokucoca umbhobho ngokuzenzekelayo

Inkqubo yokuthambisa: isixhobo sokuthambisa esizenzekelayo

III. Imisebenzi kunye neziphumo

Ukuchongwa kwecandelo: Chola ngokuchanekileyo amacandelo e-SMD eenkcazo ezahlukeneyo kwi-feeder

Ukufunyanwa kwelungu: Jonga ukuba icandelo licholwa ngokuqhelekileyo ngesifunxa

Ukugxilwa kwecandelo: Lungisa indawo kunye ne-angle yecandelo ngokubonwayo okanye ngoomatshini

Ukubekwa ngokuchanekileyo: Beka ngokuchanekileyo icandelo kwindawo echaziweyo yePCB ngoxinzelelo oluseti kunye ne-angle.

Ulawulo lombhobho: Chonga ngokuzenzekelayo kwaye ubuyisele imilomo yeempawu ezahlukeneyo

Ukujongwa kwenkqubo: Ukujongwa kwexesha lokwenyani kwiiparamitha ezahlukeneyo ngexesha lenkqubo yokubeka

IV. Iimpazamo eziqhelekileyo kunye nolwazi oluphosakeleyo

1. Ukusilela koomatshini

I-E101: Impazamo ye-Z-axis ngaphezulu komda - intshukumo ye-Z-axis idlula uluhlu olumiselweyo

E205: Intonga yombhobho ixingile - Intonga yomlomo ayikwazi ukunyuka ihle ngokwesiqhelo

E307: θ-impazamo yokumisa i-axis - I-axis yokujikeleza ayikwazi ukufikelela kwi-angle echaziweyo

2. Ukungaphumeleli kwenkqubo yevacuum

E401: Ukungaphumeleli kokusekwa kwevacuum-Akukwazi ukuseka isifunxa esaneleyo sokuchola

E402: Ukuvuza kwevacuum - ivacuum yehla ngokukhawuleza emva kokuchola

I-E403: Ukusilela kokukhutshwa kwevacuum-akukwazi ukukhulula icandelo emva kokunyuka

3. Ukusilela koluvo

E501: Ukuphakama kwesivamvo esingaqhelekanga

I-E502: Ilahleko yesiginali yeKhowudi

E503: Inzwa yobushushu ingaphaya komda

4. Ukusilela kwenkqubo ye-elektroniki

E601: Ukusilela kwe-Servo drive

E602: Uphazamiseko lonxibelelwano lwebhodi yokulawula

E603: Umbane wombane ongaqhelekanga

V. Iindlela zogcino

1. Ulondolozo lwemihla ngemihla

Umsebenzi wokucoca:

Coca i-nozzle kunye nentonga ye-nozzle yonke imihla

Coca isihluzi sevacuum

Susa uthuli kunye nentsalela ejikeleze intloko yomsebenzi

Umsebenzi wokuthambisa:

Gcoba iileyili zesikhokelo kunye nezikrufu zokukhokela rhoqo ngokweemfuno zemanuwali

Sebenzisa uhlobo oluchaziweyo lwegrisi

Umsebenzi wokuhlola:

Khangela ukuba ngaba uluvo ngalunye lusebenza ngokufanelekileyo

Khangela ukuba uxinzelelo lwenkqubo yevacuum luqhelekileyo

Jonga ukuba kukho izandi ezingaqhelekanga kwindawo nganye ehambayo

2. Ukugcinwa rhoqo

Ukugcinwa kwenyanga:

Coca ngokucokisekileyo yonke intloko yomsebenzi

Jonga kwaye ubuyisele i-O-rings ezigugileyo

Lungiselela indawo yokuchaneka kwe-axis nganye

Ukugcinwa kwekota:

Faka endaweni yesihluzi sevacuum

Jonga kwaye ulungise ukunyanzeliswa kwebhanti

Lungiselela ngokupheleleyo inkqubo yokubonwayo

Ukugcinwa konyaka:

Tshintsha amalungu omatshini agugileyo

Jonga ngokupheleleyo inkqubo yombane

Yenza uvavanyo olubanzi lokusebenza

VI. Izimvo zogcino

1. Inkqubo yokuxilongwa kwempazamo

Qwalasela isenzeko: rekhoda ikhowudi yempazamo kunye nesimo somatshini

Hlalutya oonobangela abanokubakho: Dwelisa oonobangela abanokubakho ngokwencwadana namava

Inyathelo ngenyathelo lokusombulula ingxaki: Jonga nganye nganye ukusuka kokulula ukuya kokuntsonkothileyo

Qinisekisa kwaye ulungise: Vavanya kwaye uqinisekise emva kokulungiswa

2. Ukuphatha iimpazamo eziqhelekileyo

Ukubekwa kokulinganisa:

Jonga ulungelelwaniso lwesixokelelwano esibonakalayo

Jonga i-mechanical centering mechanism

Jonga isignali ye-encoder

Ukusilela kokulanda icandelo:

Qwalasela inkqubo vacuum

Jonga ukhetho lomlomo kunye nokunxiba

Jonga indawo yokutya

Intshukumo engaqhelekanga:

Jonga i-servo drive kunye nemoto

Jonga amacandelo othumelo ngoomatshini

Jonga isivamvo sendawo

3. Amanyathelo olondolozo

Ukhuseleko kuqala: Yenza ulungiso lomatshini emva kokucima kombane

Amanyathelo achasene ne-static: Thatha ukhuseleko lwe-anti-static xa uphethe amacandelo e-elektroniki

Sebenzisa iindawo ezisecaleni zokwenyani: Zama ukusebenzisa iindawo ezizezinye

Rekhoda inkqubo yolondolozo: Rekhoda amanyathelo olondolozo kunye neendawo ezitshintshiweyo ngokweenkcukacha

VII. Iindlela zoPhuhliso lweTekhnoloji

Isantya esiphezulu: Yamkela uyilo olulula kunye nenkqubo yokuqhuba ngokukhawuleza

Ukuchaneka okuphezulu: ukusetyenziswa kweteknoloji ye-nano-positioning

Ubukrelekrele: hlanganisa abenzi boluvo abaninzi ukufezekisa ukugcinwa kwangaphambili

Uyilo lwemodyuli: ilungele ukutshintshwa ngokukhawuleza kunye nokulungiswa

Ukuhlanganiswa kwemisebenzi emininzi: hlanganisa imisebenzi emininzi yokufumanisa kwintloko yomsebenzi

Ngokuqonda oku ngasentla kwesakhiwo, umsebenzi, ukugcinwa kunye neendlela zokulungiswa kwentloko yomsebenzi we-CPP, ungasebenzisa kakuhle kunye nokugcina umatshini wokubeka i-ASM ukuqinisekisa ukusebenza okuzinzile kunye nokusebenza kakuhle komgca wokuvelisa.