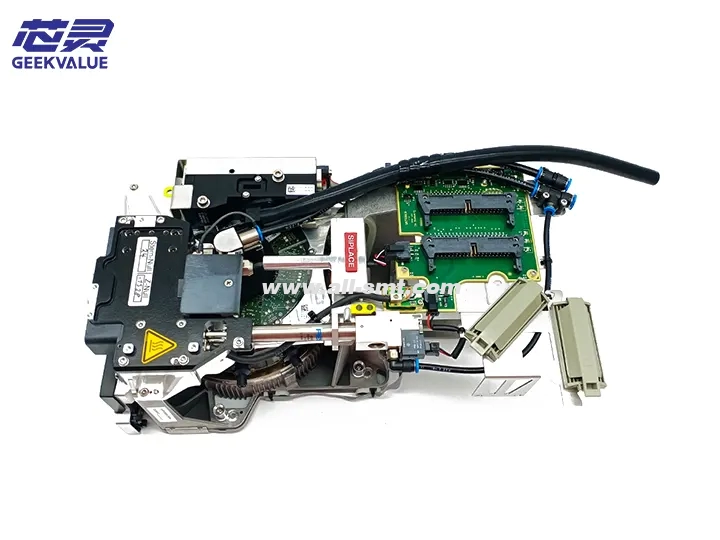

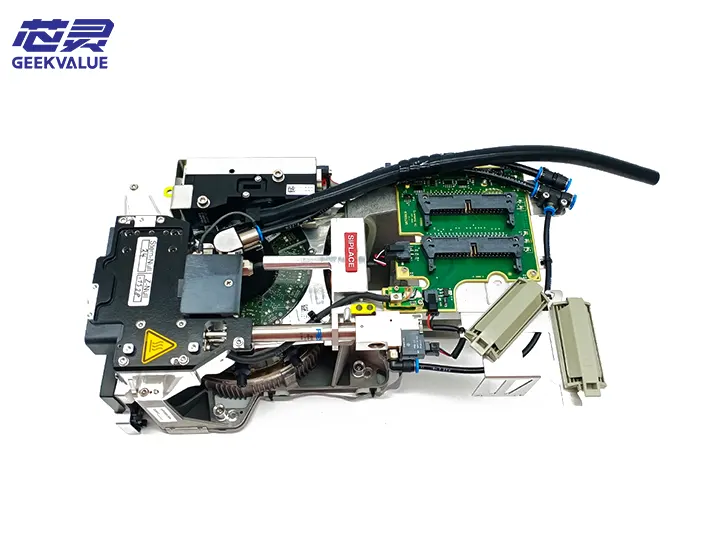

The CPP (Component Placement Head) work head is the core component of the ASM placement machine, responsible for picking up components from the feeder and accurately placing them on the PCB board. The CPP work head of ASM (now Siemens Electronic Assembly Systems Division) enjoys a high reputation in the SMT industry for its high precision, high speed and high reliability.

2. Structural composition

1. Mechanical structure

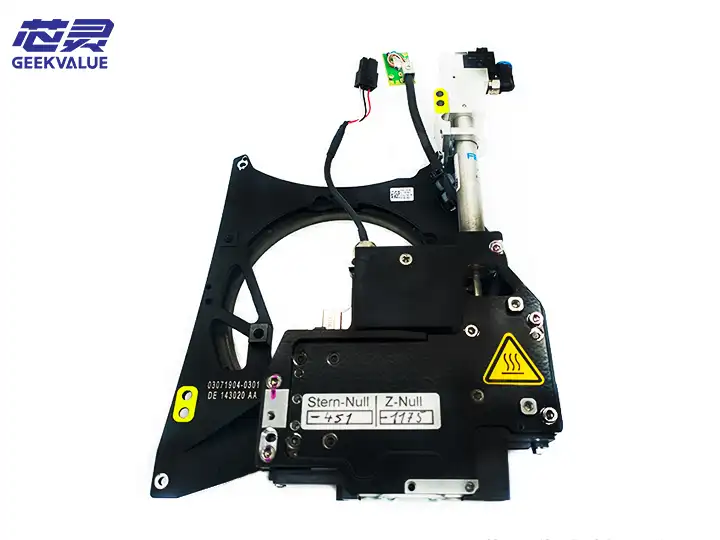

Spindle system: includes servo motor, high-precision ball screw and linear guide

Nozzle rod: replaceable nozzle mounting rod, usually with 12 or 16 stations

Vacuum system: includes vacuum generator, vacuum sensor and vacuum channel

Centering system: visual system and mechanical centering claw for component centering

Z-axis drive: servo or pneumatic system to control placement height

θ-axis rotation: stepper or servo motor for component angle rotation

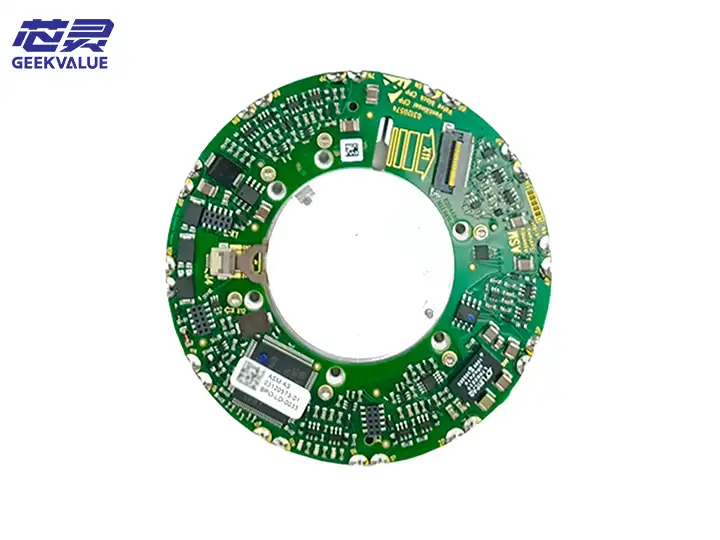

2. Electronic system

Encoder system: high-resolution encoder for precise positioning

Sensor system:

Vacuum sensor

Height sensor

Position sensor

Temperature sensor

Control board: dedicated control circuit board

3. Auxiliary system

Nozzle replacement device: automatic or semi-automatic nozzle replacement mechanism

Cleaning system: automatic nozzle cleaning device

Lubrication system: automatic lubrication device

III. Functions and effects

Component picking: Accurately pick up SMD components of various specifications from the feeder

Component detection: Check whether the component is picked up normally through vacuum

Component centering: Correct the position and angle of the component by visual or mechanical means

Precise placement: Accurately place the component on the specified position of the PCB with the set pressure and angle

Nozzle management: Automatically identify and replace nozzles of different specifications

Process monitoring: Real-time monitoring of various parameters during the placement process

IV. Common errors and fault information

1. Mechanical failures

E101: Z-axis over-limit error - Z-axis movement exceeds the set range

E205: Nozzle rod stuck - Nozzle rod cannot move up and down normally

E307: θ-axis positioning error - Rotation axis cannot reach the specified angle

2. Vacuum system failure

E401: Vacuum establishment failure - Unable to establish sufficient vacuum for picking

E402: Vacuum leak - vacuum drops too quickly after picking

E403: Vacuum release failure - unable to release component after mounting

3. Sensor failure

E501: Height sensor abnormality

E502: Encoder signal loss

E503: Temperature sensor out of limit

4. Electronic system failure

E601: Servo drive failure

E602: Control board communication interruption

E603: Power supply voltage abnormality

V. Maintenance methods

1. Daily maintenance

Cleaning work:

Clean the nozzle and nozzle rod daily

Clean the vacuum filter

Remove dust and residue around the work head

Lubrication work:

Lubricate the guide rails and lead screws regularly according to the manual requirements

Use the specified type of grease

Inspection work:

Check whether each sensor is working properly

Check whether the vacuum system pressure is normal

Check whether there are abnormal sounds in each moving part

2. Regular maintenance

Monthly maintenance:

Thoroughly clean the entire work head

Check and replace worn O-rings

Calibrate the position accuracy of each axis

Quarterly maintenance:

Replace the vacuum filter

Check and adjust the belt tension

Fully calibrate the visual system

Annual maintenance:

Replace worn mechanical parts

Fully check the electrical system

Perform comprehensive performance test

VI. Maintenance ideas

1. Fault diagnosis process

Observe the phenomenon: record the fault code and machine status

Analyze possible causes: List possible causes according to the manual and experience

Step-by-step troubleshooting: Check one by one from simple to complex

Verify and repair: Test and verify after repair

2. Common fault handling

Placement offset:

Check visual system calibration

Check mechanical centering mechanism

Check encoder signal

Component pickup failure:

Check vacuum system

Check nozzle selection and wear

Check feeder position

Abnormal movement:

Check servo drive and motor

Check mechanical transmission components

Check position sensor

3. Maintenance precautions

Safety first: Perform mechanical maintenance after power off

Anti-static measures: Take anti-static protection when handling electronic components

Use genuine spare parts: Try to use original spare parts

Record the maintenance process: Record the maintenance steps and replacement parts in detail

VII. Technology Development Trends

Higher speed: adopt lighter design and faster drive system

Higher precision: application of nano-positioning technology

Intelligence: integrate more sensors to achieve predictive maintenance

Modular design: convenient for quick replacement and repair

Multi-function integration: integrate more detection functions into the work head

Through the above comprehensive understanding of the structure, function, maintenance and repair methods of the CPP work head, you can better use and maintain the ASM placement machine to ensure the stable and efficient operation of the production line.