Mutu wa ntchito ya CPP (Component Placement Head) ndiye chigawo chachikulu cha makina oyika a ASM, omwe ali ndi udindo wotola zinthu kuchokera ku feeder ndikuziyika molondola pa bolodi la PCB. Mtsogoleri wa ntchito ya CPP wa ASM (tsopano Siemens Electronic Assembly Systems Division) amasangalala ndi mbiri yabwino mu makampani a SMT chifukwa cha kulondola kwake, kuthamanga kwambiri komanso kudalirika kwambiri.

2. Mapangidwe apangidwe

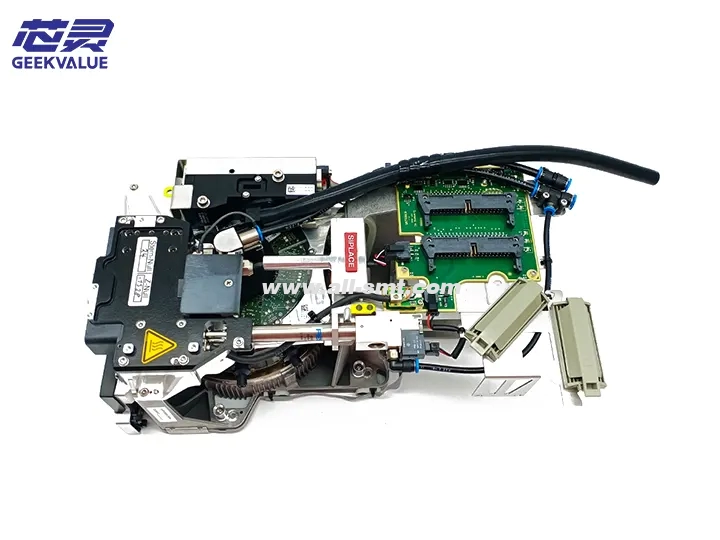

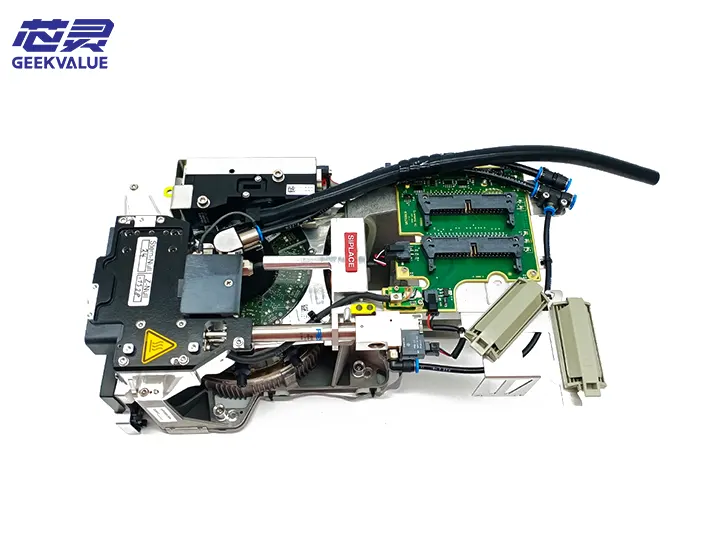

1. Kapangidwe ka makina

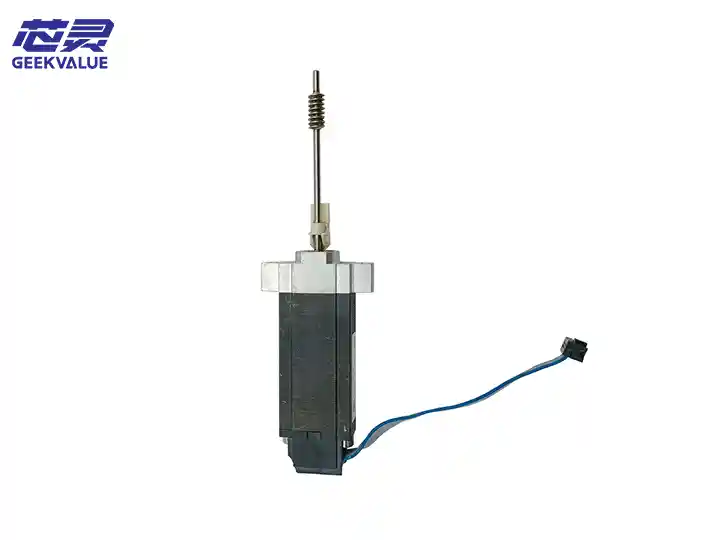

Spindle system: imaphatikizapo servo motor, high-decision ball screw ndi linear guide

Ndodo ya Nozzle: ndodo yosinthira nozzle, nthawi zambiri imakhala ndi masiteshoni 12 kapena 16

Vacuum System: imaphatikizapo vacuum generator, vacuum sensor ndi vacuum channel

Centering system: zowonera ndi makina opaka claw pagawo lapakati

Z-axis drive: servo kapena pneumatic system kuwongolera kutalika kwa malo

θ-axis kuzungulira: stepper kapena servo motor pakuzungulira kozungulira

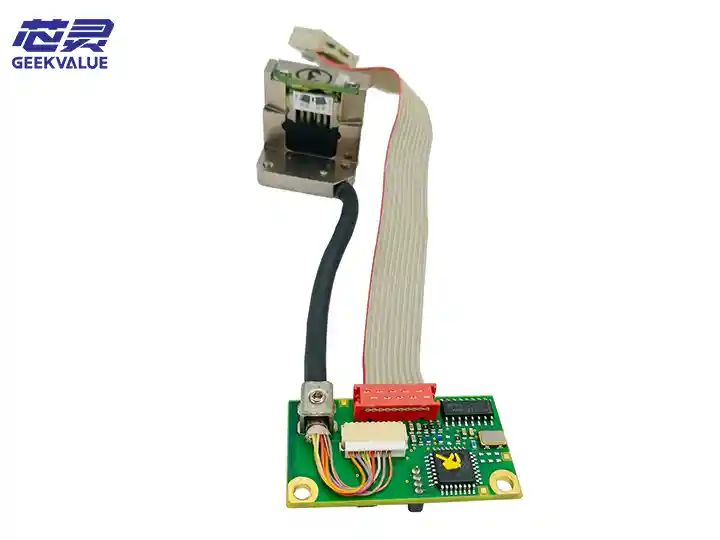

2. Dongosolo lamagetsi

Encoder system: encoder yokhazikika kwambiri kuti muyike bwino

Sensor System:

Sensa ya vacuum

Sensa ya kutalika

Sensor ya udindo

Sensa ya kutentha

Gulu lowongolera: gulu lodzipatulira loyang'anira dera

3. Dongosolo lothandizira

Chida chosinthira cha nozzle: makina osinthika kapena odziyimira pawokha

Makina otsuka: chipangizo chotsuka chodziwikiratu

Dongosolo lopaka mafuta: chipangizo chothira mafuta

III. Ntchito ndi zotsatira

Kutola zinthu: Tengani molondola zigawo za SMD zamitundu yosiyanasiyana kuchokera ku feeder

Kuzindikira kwachinthu: Onani ngati chigawocho chimatengedwa nthawi zonse kudzera mu vacuum

Chigawo chapakati: Konzani malo ndi mbali ya chigawocho pogwiritsa ntchito mawonekedwe kapena makina

Kuyika kolondola: Ikani bwino gawolo pamalo omwe atchulidwa pa PCB ndi kukakamiza kokhazikitsidwa ndi ngodya.

Kasamalidwe ka Nozzle: Zindikirani ndikusintha ma nozzles osiyanasiyana

Kuyang'anira ndondomeko: Kuyang'anira nthawi yeniyeni ya magawo osiyanasiyana panthawi yoyika

IV. Zolakwika zofala ndi zolakwika zambiri

1. Kulephera kwamakina

E101: Z-axis over-limit error - Z-axis movement imadutsa mulingo wokhazikitsidwa

E205: Ndodo ya mphuno yomata - Ndodo ya mphuno sikhoza kusuntha mmwamba ndi pansi nthawi zonse

E307: θ-axis poyikira zolakwika - Mzere wozungulira sungathe kufika pangodya yotchulidwa

2. Kulephera kwa dongosolo la vacuum

E401: Kulephera kukhazikitsa vacuum - Kulephera kukhazikitsa vacuum yokwanira kutola

E402: Kutayikira kwa vacuum - vacuum imatsika mwachangu mukatha kutola

E403: Kulephera kwa vacuum - kulephera kutulutsa chigawocho pambuyo kukwera

3. Kulephera kwa sensa

E501: Kusakhazikika kwa sensor ya kutalika

E502: Kutayika kwa chizindikiro cha encoder

E503: Sensa ya kutentha kunja kwa malire

4. Kulephera kwadongosolo lamagetsi

E601: Kulephera kwa galimoto ya Servo

E602: Kusokoneza kulumikizana kwa board board

E603: Kuwonongeka kwamagetsi kwamagetsi

V. Njira zosamalira

1. Kusamalira tsiku ndi tsiku

Ntchito yoyeretsa:

Tsukani nozzle ndi ndodo tsiku lililonse

Chotsani zosefera

Chotsani fumbi ndi zotsalira kuzungulira mutu wa ntchito

ntchito mafuta:

Patsani mafuta njanji zowongolera ndi zomangira zotsogola pafupipafupi malinga ndi zofunikira pamanja

Gwiritsani ntchito mafuta amtundu wotchulidwawo

Ntchito yoyendera:

Onani ngati sensa iliyonse ikugwira ntchito bwino

Onani ngati kuthamanga kwa vacuum system ndikwabwinobwino

Onani ngati pali mawu achilendo pagawo lililonse losuntha

2. Kusamalira nthawi zonse

Kukonza pamwezi:

Chotsani bwino mutu wonse wa ntchito

Yang'anani ndikusintha mphete za O-rings zomwe zidatha

Yang'anirani kulondola kwa malo a axis iliyonse

Kukonza kotala:

Bwezerani zosefera

Yang'anani ndikusintha kuthamanga kwa lamba

Konzani bwino dongosolo lowonera

Kukonza kwapachaka:

Sinthani zida zamakina zomwe zidatha

Yang'anani kwathunthu dongosolo lamagetsi

Chitani mayeso athunthu a magwiridwe antchito

VI. Malingaliro osamalira

1. Njira yodziwira zolakwika

Zindikirani chodabwitsa: lembani nambala yolakwika ndi momwe makina alili

Unikani zomwe zingatheke: Lembani zomwe zingatheke molingana ndi bukhuli komanso zomwe mwakumana nazo

Kuthetsa zovuta pang'onopang'ono: Yang'anani imodzi ndi imodzi kuchokera pa zosavuta mpaka zovuta

Tsimikizirani ndi kukonza: Yesani ndikutsimikizira mukamaliza kukonza

2. Kusamalira zolakwika wamba

Kuyikirapo:

Yang'anani mawonedwe a dongosolo la mawonedwe

Chongani makina centering limagwirira

Onani chizindikiro cha encoder

Kulephera kunyamula zinthu:

Onani vacuum system

Onani kusankha kwa nozzle ndi kuvala

Onani malo a feeder

Kuyenda kwachilendo:

Onani servo drive ndi mota

Chongani makina kufala zigawo zikuluzikulu

Onani malo sensa

3. Njira zodzitetezera

Chitetezo choyamba: Chitani kukonza makina mukatha kuzimitsa

Njira zotsutsana ndi ma static: Tengani chitetezo cha anti-static mukamagwira zida zamagetsi

Gwiritsani ntchito zida zosinthira zenizeni: Yesani kugwiritsa ntchito zida zosinthira zoyambirira

Lembani ndondomeko yokonza: Lembani masitepe okonza ndi zina zowonjezera mwatsatanetsatane

VII. Tekinoloje Zachitukuko

Kuthamanga kwakukulu: tengerani mapangidwe opepuka komanso makina oyendetsa mwachangu

Kulondola kwambiri: kugwiritsa ntchito ukadaulo wa nano-positioning

Luntha: Phatikizani masensa ambiri kuti mukwaniritse zolosera zam'tsogolo

Mapangidwe a modular: osavuta kusinthidwa mwachangu komanso kukonza

Kuphatikizika kwamitundu yambiri: kuphatikiza ntchito zambiri zodziwikiratu pamutu wantchito

Kupyolera mu chidziwitso chapamwamba cha mapangidwe, ntchito, kukonza ndi kukonza njira za mutu wa ntchito ya CPP, mungagwiritse ntchito bwino ndi kusunga makina opangira ASM kuti mutsimikizire kugwira ntchito mokhazikika komanso moyenera kwa mzere wopanga.