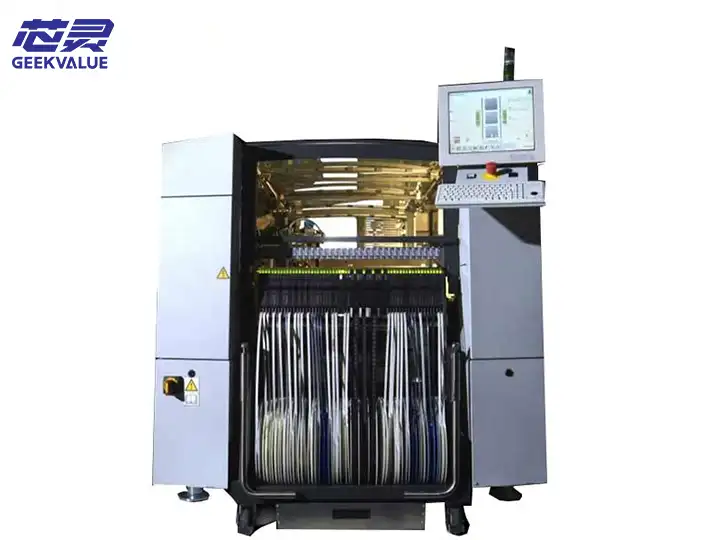

Siemens SIPLACE HS60 waa mishiin meelaynta modular-xawaaraha sare leh oo uu bilaabay Siemens Electronic Assembly Systems, oo ka tirsan SIPLACE taxanaha xawaaraha sare ee caadiga ah. Qalabka waxaa loogu talagalay wax soo saarka elegtarooniga ah ee mugga sare leh, gaar ahaan:

Qalabka elektarooniga ah ee macaamiisha (telefoonada gacanta, tablets)

Qalabka elektiroonigga ah (nidaamka madadaalada baabuurta)

Qalabka isgaadhsiinta (Routers, switches)

Qalabka kontoroolka qalabka guriga

II. Mabaadi'da tignoolajiyada aasaasiga ah

1. Nidaamka dhaqdhaqaaqa xawaaraha sare leh

Hawl-gal madax-bannaan oo laba-geesood ah: 2 hawl-gal is-bar-bar-dhigeed oo madaxbannaan si loo gaaro meelayn hufan

Madaxa meelaynta munaaradda Rotary: 12 nozzle rotary head design, xawaaraha ugu badan ee 60,000CPH

Wadaadka levitation birlabeedka toosan: dhidibka X/Y waxa uu isticmaalaa wadiiqooyin toosan, dardargelinta 3.5G

2. Nidaamka meelaynta aragga

Tiknoolajiyada udub dhexaad u ah duulista: aqoonsiga qaybaha dhamaystiran iyo meelaynta inta lagu jiro habka meelaynta

Nidaamka kamaradaha laba-geesoodka ah:

Kamarad caalami ah oo heer sare ah (oo loogu talagalay meelaynta PCB)

Kamarad maxalli ah oo sax ah oo saraysa (si loo aqoonsado qaybaha)

3. Nidaamka quudinta

Goobta quudiyaha caqliga leh:

Taageer 8mm ~ 56mm cajalad quudiyaha

Xakamaynta cajalka toosan

Aqoonsiga tooska ah ee feederiyaha

III. Tilmaamaha muhiimka ah iyo xuduudaha

Tilmaamaha Halbeegyada

Saxnaanta meelaynta ± 50μm @ 3σ

Xawaaraha meelaynta 60,000 CPH (ugu badnaan aragtida)

Qaybaha kala duwan 0402 ~ 24×24mm (dhererka 12.7mm)

Awoodda quudiyaha Ilaa 72 8mm cajalad quudiye

Cabbirka looxa 50 × 50mm ~ 457×356mm

Baahida tamarta 400VAC 3 waji 7kVA

IV. Faa'iidooyinka asaasiga ah

1. Xawaaraha aadka u sarreeya

Xawaaraha meelaynta CPH ee hogaaminaya warshadaha 60k

0.06 ilbiriqsi/chip meertada meelaynta

Dual cantilever oo wada shaqaynaya

2. Deggan oo la isku halayn karo

Qaab dhismeed farsamo oo heer warshadeed ah oo ruxsan

<1000ppm heerka cilladda meelaynta

Nidaamka qaladka-cadaynta tooska ah

3. Kharash wax ku ool ah

Qiimaha meelaynta hooseeya halkii dhibic

Soo celinta degdega ah ee maalgashiga (badanaa <18 bilood)

Naqshadaynta dayactirka hooseeya

V. Astaamaha qalabka

1. Madaxa meelaynta cusub

Naqshadda munaaradda wareegta: 12 nozzles ayaa si joogto ah u wareegaya

Xulashada biibiile ee caqliga leh: si toos ah u dooro nozzle-ka ugu fiican

Nidaamka xakamaynta vacuum: kanaalka vacuum si madax banaan loo xakameeyo

2. Nidaamka aragga

Tignoolajiyada udub dhexaad u ah duulista waxay yaraynaysaa wakhtiga hakadka

Nidaamka kamaradaha laba-geesoodka ah ayaa hagaajiya saxnaanta aqoonsiga

Isku hagaajin toos ah

3. Nidaamka quudinta

Naqshad beddelka quudiyaha degdega ah

Kormeerka heerka cajalad

La'aanta shaqada digniinta agabka

VI. Qaybaha shaqaynaya

1. Nidaamka xakamaynta meelaynta

Algorithm hagaajinta habka dhaqdhaqaaqa

Maaraynta xogta qaybaha

Hagaajinta barnaamijka

2. Nidaamka hubinta tayada

Shaqada kormeerida cutubka koowaad

la socodka habka meelaynta

Shaqada duubista xogta

3. Nidaamka maaraynta wax soo saarka

La socodka xaaladda qalabka

Tirakoobka waxtarka wax-soo-saarka

Falanqaynta qaladka diiwaanka

VII. Ka-hortagga isticmaalka

1. Shuruudaha deegaanka

Heerkulka: 20± 3℃

Qoyaanka: 40-70% RH

Gariir: <0.5G (aasaaska xasiloon ayaa loo baahan yahay)

2. Hawlgalka maalinlaha ah

Samee hagaajin degdeg ah ka hor inta aanad bilaabin mashiinka maalin kasta

Si joogto ah u nadiifi sanbabada (waxaa lagu talinayaa 4-tii saacadoodba mar)

Isticmaal alaabta asalka ah (nozzles, feeders, iwm.)

3. Dayactirka

Waxyaabaha ku jira meerto shayga

Kormeerka nozzle-ka maalin kasta Hubi xidhashada iyo nadiifinta

Sifeynta Hagaha Dayactirka toddobaadlaha ah oo leh saliid saliid saliideed oo gaar ah

Isku-habaynta kamarada bishiiba mar Isticmaal looxa cabirka caadiga ah

Kormeer dhamaystiran oo rubac-biloodle ah ay sameeyaan injineero xirfad leh

VIII. Cilladaha guud iyo xalalka

1. Khalad: Soo qaadis xun

Sababaha suurtagalka ah:

Xiritaanka sanka

Faakuum aan ku filnayn

Dejinta dhumucda qaybta khaldan

Xalka:

Nadiifi ama baddal sanbabada

Hubi nidaamka vacuum

Dib u qiyaas dhumucda qaybta

2. Khalad: Qaladka aqoonsiga qaybaha

Sababaha suurtagalka ah:

Wasakhda muraayadda kamarada

Goob iftiin aan habboonayn

Xogta qaybta khaldan

Xalka:

Nadiifi muraayadda kamarada

Hagaajin cabbirka iftiinka

Hubi xogta qaybta

3. Khalad: qaylo-dhaanta nidaamka dhaqdhaqaaqa

Sababaha suurtagalka ah:

Shil makaanik ah

Servo wad aan caadi ahayn

Saliida tareenka oo aan ku filnayn

Xalka:

Hubi qaabka farsamada

Dib u bilow nidaamka servo

Saliid hagaha toosan

IX. Fikradaha dayactirka

1. Cilad habaysan

U fiirso ifafaalaha: qor lambarka digniinta iyo heerka qalabka

Falanqee sababaha suurtogalka ah: tixraac buug-gacmeedka si aad u go'aamiso baaxadda cilladdu

Tillaabo tallaabo tallaabo ah tirtirista: iska hubi min fudud ilaa kakan

2. Qaybta muhiimka ah ee taxanaha kormeerka

Nuugista nuugista iyo nidaamka vacuum

Heerka quudiyaha

Nidaamka muuqaalka

Habka dhaqdhaqaaqa

Nidaamka xakamaynta

3. Taageerada xirfadeed

Isticmaal software-ka ogaanshaha SIPLACE

La xidhiidh Siemens taageero farsamo

Ku beddel qaybaha kaydka qaybo asalka ah

10. Meelaynta suuqa

Qalabka La Doorbiday ee Wax Soo Saarka Badan

Guud ahaan wax soo saarka Elektrooniga ee Macmiilka

Moodel Xawaaraha Sare leh oo leh qiimo-sare leh

11. Kooban

Siemens SIPLACE HS60 SMT Machine waa doorashada ugu fiican ee wax soo saarka elektaroonigga ballaaran ee leh:

Xawaaraha 60k CPH ee hogaaminaya warshadaha

Tayada SMT oo deggan

Dhaqaale iyo kharashyo hawleed oo hufan

Waa doorashada ugu fiican ee wax soo saarka elektarooniga ah ee tirada badan. Iyada oo loo marayo dayactirka maalinlaha ah ee caadiga ah iyo cilad-bixinta sayniska, qalabka waxaa lagu xaqiijin karaa inuu si deggan u shaqeeyo muddo dheer, iyadoo la siinayo dammaanad lagu kalsoonaan karo oo soo saarista tayada sare leh ee elektiroonigga ah.