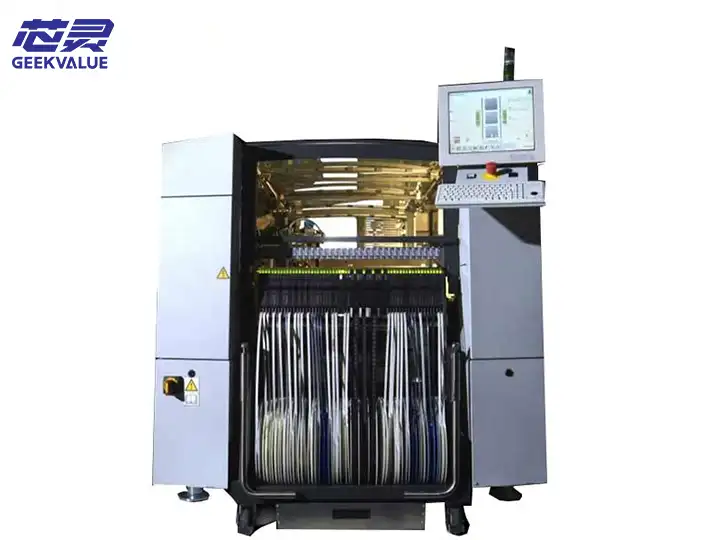

Siemens SIPLACE HS60 ເປັນເຄື່ອງຈັດວາງແບບໂມດູລາຄວາມໄວສູງສຸດທີ່ເປີດຕົວໂດຍ Siemens Electronic Assembly Systems, ເປັນຂອງ SIPLACE ຊຸດຄວາມໄວສູງຄລາສສິກ. ອຸປະກອນໄດ້ຖືກອອກແບບສໍາລັບການຜະລິດເອເລັກໂຕຣນິກປະລິມານສູງ, ໂດຍສະເພາະສໍາລັບ:

ເຄື່ອງເອເລັກໂຕຣນິກການບໍລິໂພກ (ໂທລະສັບມືຖື, ແທັບເລັດ)

ເຄື່ອງເອເລັກໂຕຣນິກລົດຍົນ (ລະບົບບັນເທີງລົດ)

ອຸປະກອນສື່ສານ (ເຣົາເຕີ, ສະວິດ)

ແຜງຄວບຄຸມເຄື່ອງໃຊ້ໃນເຮືອນ

II. ຫຼັກການເຕັກໂນໂລຊີຫຼັກການ

1. ລະບົບການເຄື່ອນໄຫວຄວາມໄວສູງ

ການດໍາເນີນງານແບບເອກະລາດຂອງ cantilever ຄູ່: 2 ການປະຕິບັດການ synchronous cantilever ເອກະລາດເພື່ອບັນລຸການຈັດວາງຂະຫນານທີ່ມີປະສິດທິພາບ

ຫົວການຈັດວາງຫໍ rotary: ການອອກແບບຫົວ rotary 12 nozzle, ຄວາມໄວສູງສຸດຂອງ 60,000CPH

ໄດຣຟ໌ລອຍແມ່ເຫຼັກເສັ້ນຊື່: ແກນ X/Y ໃຊ້ການຂັບເຄື່ອນມໍເຕີແບບເສັ້ນ, ການເລັ່ງ 3.5G

2. ລະບົບການຈັດຕໍາແຫນ່ງວິໄສທັດ

ເຕັກໂນໂລຊີການຈັດຕັ້ງສູນກາງຂອງການບິນ: ການກໍານົດອົງປະກອບທີ່ສົມບູນແລະຕໍາແຫນ່ງໃນລະຫວ່າງຂະບວນການຈັດວາງ

ລະບົບກ້ອງຄູ່:

ກ້ອງຖ່າຍຮູບລະດັບໂລກຄວາມລະອຽດສູງ (ສໍາລັບຕໍາແຫນ່ງ PCB)

ກ້ອງຖ່າຍຮູບທ້ອງຖິ່ນທີ່ມີຄວາມຊັດເຈນສູງ (ສໍາລັບການກໍານົດອົງປະກອບ)

3. ລະບົບການໃຫ້ອາຫານ

ແພລະຕະຟອມ feeder ອັດສະລິຍະ:

ຮອງຮັບ tape feeder 8mm ~ 56mm

ການຄວບຄຸມຄວາມກົດດັນ tape ອັດຕະໂນມັດ

ການລະບຸອັດຕະໂນມັດ feeder

III. ຂໍ້ມູນສະເພາະ ແລະຕົວກໍານົດການຫຼັກ

ຂໍ້ມູນຈໍາເພາະຂອງພາລາມິເຕີ

ຄວາມຖືກຕ້ອງຂອງການຈັດວາງ ±50μm @ 3σ

ຄວາມໄວການຈັດວາງ 60,000 CPH (ສູງສຸດຕາມທິດສະດີ)

ລະດັບອົງປະກອບ 0402 ~ 24 × 24 ມມ (ຄວາມສູງ 12.7 ມມ)

ຄວາມອາດສາມາດຂອງ feeders ສູງເຖິງ 72 8mm tape feeders

ຂະໜາດກະດານ 50×50mm~457×356mm

ຄວາມຕ້ອງການພະລັງງານ 400VAC 3 ໄລຍະ 7kVA

IV. ຂໍ້ໄດ້ປຽບຫຼັກ

1. ຄວາມໄວສູງສຸດ

ຄວາມໄວການຈັດວາງ 60k CPH ຊັ້ນນໍາໃນອຸດສາຫະກໍາ

0.06 ວິນາທີ/ວົງຈອນການຈັດວາງຊິບ

cantilever ສອງເຮັດວຽກຮ່ວມກັນ

2. ຫມັ້ນຄົງແລະເຊື່ອຖືໄດ້

ໂຄງປະກອບການກົນຈັກຊັ້ນອຸດສາຫະກໍາ Rugged

<1000ppm ອັດຕາຄວາມບົກພ່ອງການຈັດວາງ

ລະບົບປ້ອງກັນຄວາມຜິດພາດອັດຕະໂນມັດ

3. ຄຸ້ມຄ່າ

ຄ່າໃຊ້ຈ່າຍໃນການຈັດວາງຕ່ໍາຕໍ່ຈຸດ

ຜົນຕອບແທນຈາກການລົງທຶນໄວ (ປົກກະຕິ <18 ເດືອນ)

ການອອກແບບການບໍາລຸງຮັກສາຕ່ໍາ

V. ລັກສະນະອຸປະກອນ

1. ຫົວຫນ້າການຈັດວາງນະວັດຕະກໍາ

ການອອກແບບ tower ພືດຫມູນວຽນ: 12 nozzles rotate ຢ່າງຕໍ່ເນື່ອງ

ການຄັດເລືອກ nozzle ອັດສະລິຍະ: ອັດຕະໂນມັດເລືອກ nozzle ທີ່ດີທີ່ສຸດ

ລະບົບສູນຍາກາດຄວບຄຸມ: ຊ່ອງທາງສູນຍາກາດຄວບຄຸມເອກະລາດ

2. ລະບົບວິໄສທັດ

ເທັກໂນໂລຍີການວາງຈຸດກາງຂອງການບິນຊ່ວຍຫຼຸດເວລາຢຸດຊົ່ວຄາວ

ລະບົບກ້ອງຖ່າຍຮູບຄູ່ປັບປຸງຄວາມຖືກຕ້ອງຂອງການຮັບຮູ້

ການປັບແສງອັດຕະໂນມັດ

3. ລະບົບການໃຫ້ອາຫານ

ການອອກແບບການທົດແທນ feeder ໄວ

ການຕິດຕາມສະຖານະຂອງເທບ

ຂາດການທໍາງານຂອງການເຕືອນໄພວັດສະດຸ

VI. ໂມດູນທີ່ມີປະໂຫຍດ

1. ລະບົບການຄວບຄຸມການຈັດວາງ

ຂັ້ນຕອນການເພີ່ມປະສິດທິພາບຂອງເສັ້ນທາງການເຄື່ອນໄຫວ

ການຈັດການຖານຂໍ້ມູນອົງປະກອບ

ຟັງຊັນການເພີ່ມປະສິດທິພາບໂຄງການ

2. ລະບົບການຮັບປະກັນຄຸນນະພາບ

ການທໍາງານຂອງການກວດກາຄັ້ງທໍາອິດ

ການຕິດຕາມຂະບວນການຈັດວາງ

ຟັງຊັນບັນທຶກຂໍ້ມູນ

3. ລະບົບການຄຸ້ມຄອງການຜະລິດ

ການຕິດຕາມສະຖານະພາບອຸປະກອນ

ສະຖິຕິປະສິດທິພາບການຜະລິດ

ການວິເຄາະບັນທຶກຄວາມຜິດ

VII. ຂໍ້ຄວນລະວັງສໍາລັບການນໍາໃຊ້

1. ຄວາມຕ້ອງການດ້ານສິ່ງແວດລ້ອມ

ອຸນຫະພູມ: 20 ± 3 ℃

ຄວາມຊຸ່ມຊື່ນ: 40-70%RH

ການສັ່ນສະເທືອນ: <0.5G (ຕ້ອງການພື້ນຖານທີ່ໝັ້ນຄົງ)

2. ການດໍາເນີນງານປະຈໍາວັນ

ປະຕິບັດການປັບໄວກ່ອນທີ່ຈະເລີ່ມເຄື່ອງທຸກໆມື້

ລ້າງຫົວຫົວເປັນປະຈຳ (ແນະນຳທຸກໆ 4 ຊົ່ວໂມງ)

ໃຊ້ເຄື່ອງບໍລິໂພກຕົ້ນສະບັບ (ຫົວຫົວ, ເຄື່ອງປ້ອນ, ແລະອື່ນໆ)

3. ບໍາລຸງຮັກສາ

ເນື້ອໃນຮອບວຽນລາຍການ

Nozzle inspection ປະຈໍາວັນ ກວດສອບການສວມໃສ່ແລະທໍາຄວາມສະອາດ

ແນະນໍາ lubrication ການບໍາລຸງຮັກສາປະຈໍາອາທິດດ້ວຍນ້ໍາມັນຫລໍ່ລື່ນພິເສດ

ການປັບທຽບກ້ອງຖ່າຍຮູບປະຈໍາເດືອນການນໍາໃຊ້ຄະນະກໍານົດການປັບມາດຕະຖານ

ການກວດກາທີ່ສົມບູນແບບປະຈໍາໄຕມາດປະຕິບັດໂດຍວິສະວະກອນມືອາຊີບ

VIII. ຄວາມຜິດປົກກະຕິແລະການແກ້ໄຂ

1. ຄວາມຜິດ: ການເກັບ nozzle ບໍ່ດີ

ສາເຫດທີ່ເປັນໄປໄດ້:

ການອຸດຕັນ Nozzle

ສູນຍາກາດບໍ່ພຽງພໍ

ການຕັ້ງຄ່າຄວາມຫນາຂອງອົງປະກອບຜິດພາດ

ການແກ້ໄຂ:

ເຮັດຄວາມສະອາດຫຼືປ່ຽນ nozzle

ກວດເບິ່ງລະບົບສູນຍາກາດ

ວັດແທກຄວາມຫນາຂອງອົງປະກອບ

2. ຄວາມຜິດ: ຄວາມຜິດພາດການຮັບຮູ້ອົງປະກອບ

ສາເຫດທີ່ເປັນໄປໄດ້:

ການປົນເປື້ອນເລນກ້ອງຖ່າຍຮູບ

ການຕັ້ງຄ່າແສງສະຫວ່າງທີ່ບໍ່ຖືກຕ້ອງ

ຂໍ້ມູນອົງປະກອບຜິດ

ການແກ້ໄຂ:

ເຮັດຄວາມສະອາດເລນກ້ອງຖ່າຍຮູບ

ປັບຕົວກໍານົດການເຮັດໃຫ້ມີແສງ

ກວດເບິ່ງຖານຂໍ້ມູນອົງປະກອບ

3. ຄວາມຜິດ: ສັນຍານເຕືອນລະບົບການເຄື່ອນໄຫວ

ສາເຫດທີ່ເປັນໄປໄດ້:

ການປະທະກັນທາງກົນຈັກ

Servo drive ຜິດປົກກະຕິ

ການຫຼໍ່ລື່ນທາງລົດໄຟຄູ່ມືບໍ່ພຽງພໍ

ການແກ້ໄຂ:

ກວດເບິ່ງໂຄງສ້າງກົນຈັກ

ຣີສະຕາດລະບົບ servo

lubricate ຄູ່ມືເສັ້ນ

IX. ແນວຄວາມຄິດການບໍາລຸງຮັກສາ

1. ການແກ້ໄຂບັນຫາລະບົບ

ສັງເກດປະກົດການ: ບັນທຶກລະຫັດປຸກ ແລະສະຖານະອຸປະກອນ

ວິເຄາະສາເຫດທີ່ເປັນໄປໄດ້: ເບິ່ງຄູ່ມືເພື່ອກໍານົດຂອບເຂດຂອງຄວາມຜິດ

ຂັ້ນຕອນທີການລົບລ້າງ: ໃຫ້ກວດເບິ່ງຈາກງ່າຍດາຍໄປສະລັບສັບຊ້ອນ

2. ລໍາດັບການກວດສອບອົງປະກອບທີ່ສໍາຄັນ

ຫົວດູດ ແລະລະບົບສູນຍາກາດ

ສະຖານະ feeder

ລະບົບສາຍຕາ

ກົນໄກການເຄື່ອນໄຫວ

ລະບົບ ການຄວບຄຸມ

3. ການສະຫນັບສະຫນູນດ້ານວິຊາຊີບ

ໃຊ້ຊອບແວການວິນິດໄສ SIPLACE

ຕິດຕໍ່ຝ່າຍຊ່ວຍເຫຼືອດ້ານວິຊາການ Siemens

ປ່ຽນອາໄຫຼ່ກັບຊິ້ນສ່ວນຕົ້ນສະບັບ

10. ການຈັດຕໍາແຫນ່ງຕະຫຼາດ

ອຸປະກອນທີ່ຕ້ອງການສໍາລັບການຜະລິດມະຫາຊົນ

ກະແສຫຼັກສຳລັບການຜະລິດເຄື່ອງໃຊ້ອີເລັກໂທຣນິກ

ຮູບແບບຄວາມໄວສູງທີ່ມີຄ່າໃຊ້ຈ່າຍທີ່ມີປະສິດທິພາບສູງ

11. ບົດສະຫຼຸບ

Siemens SIPLACE HS60 SMT ເຄື່ອງແມ່ນທາງເລືອກທີ່ເຫມາະສົມສໍາລັບການຜະລິດເອເລັກໂຕຣນິກມະຫາຊົນທີ່ມີ:

ຄວາມໄວ 60k CPH ຊັ້ນນໍາໃນອຸດສາຫະກໍາ

ຄຸນະພາບ SMT ຄົງທີ່

ຄ່າໃຊ້ຈ່າຍໃນການດໍາເນີນງານທີ່ປະຫຍັດແລະປະສິດທິພາບ

ມັນເປັນທາງເລືອກທີ່ເຫມາະສົມສໍາລັບການຜະລິດເອເລັກໂຕຣນິກມະຫາຊົນ. ໂດຍຜ່ານການຮັກສາມາດຕະຖານປະຈໍາວັນແລະການແກ້ໄຂບັນຫາວິທະຍາສາດ, ອຸປະກອນສາມາດຮັບປະກັນການດໍາເນີນການຢ່າງຫມັ້ນຄົງເປັນເວລາດົນນານ, ສະຫນອງການຮັບປະກັນທີ່ເຊື່ອຖືໄດ້ສໍາລັບການຜະລິດເອເລັກໂຕຣນິກທີ່ມີຄຸນນະພາບສູງ.