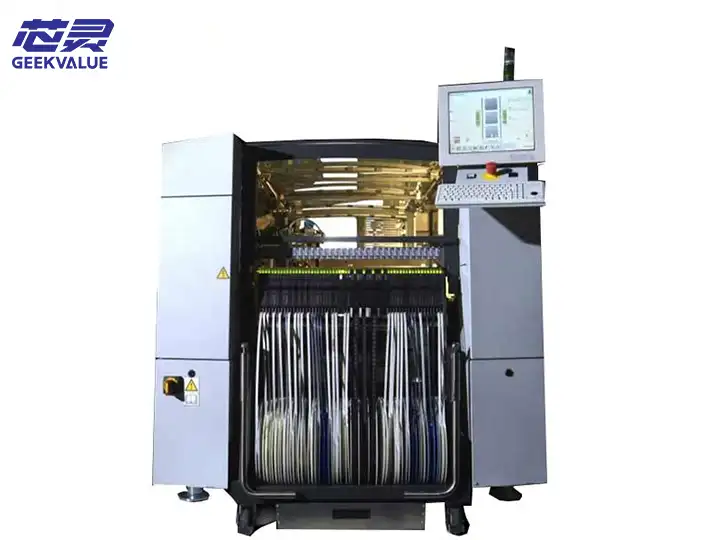

I-Siemens SIPLACE HS60 ngumatshini wokubekwa wemodyuli we-Ultra-high-speed owasungulwa yi-Siemens Electronic Assembly Systems, eyeye-SIPLACE classical high-speed series. Isixhobo senzelwe ukwenziwa komthamo omkhulu wombane, ngakumbi:

Ii-elektroniki zabathengi (iifowuni eziphathwayo, iitafile)

Ii-elektroniki zemoto (iinkqubo zokuzonwabisa kwimoto)

Izixhobo zonxibelelwano (iirutha, iiswitshi)

Iiphaneli zokulawula izixhobo zasekhaya

II. Imigaqo yetekhnoloji engundoqo

1. Inkqubo yentshukumo yesantya esiphezulu

Ukusebenza kabini okuzimeleyo kwe-cantilever: I-2 ezimeleyo ye-cantilever yokusebenza ehambelanayo ukufezekisa ukubekwa ngokufanelekileyo ngokuhambelana

Intloko yokubeka i-Rotary tower: uyilo lwentloko ye-nozzle eyi-12, isantya esiphezulu se-60,000CPH

I-Linear magnetic levitation drive: I-X / Y axis isebenzisa i-motor drive, isantya se-3.5G

2. Inkqubo yokubeka umbono

Itekhnoloji ye-Flying centering: ukuchongwa kwecandelo elipheleleyo kunye nokumiswa ngexesha lenkqubo yokubeka

Inkqubo yeekhamera ezimbini:

Ikhamera yelizwe jikelele enesisombululo esiphezulu (yokumisa kwiPCB)

Ukuchaneka okuphezulu kwekhamera yasekhaya (yokuchongwa kwecandelo)

3. Inkqubo yokutya

Iqonga lokutyisa elikrelekrele:

Inkxaso 8mm ~ 56mm tape feeder

Iteyiphu ezenzekelayo yokulawula uxinzelelo

Ukuchongwa okuzenzekelayo kwe-Feeder

III. Iimpawu eziphambili kunye neeparamitha

Iinkcazo zeeParameters

Ukuchaneka kokubekwa ±50μm @ 3σ

Isantya sokubeka 60,000 CPH (ubuninzi bethiyori)

Uluhlu lwecandelo 0402~24×24mm (ubude 12.7mm)

Umthamo we feeder Ukuya kuma 72 8mm tape feeders

Ubungakanani bebhodi 50 × 50mm ~ 457 × 356mm

Imfuno yombane 400VAC 3 isigaba 7kVA

IV. Iinzuzo eziphambili

1. Isantya esiphezulu

I-industry-ephambili ye-60k CPH yokubeka isantya

0.06 imizuzwana / umjikelo wokubekwa kwetshiphu

Ii-cantilever ezimbini zisebenza kunye

2. Izinzile kwaye zithembekile

Ubume bomatshini obumagingxigingxi bomgangatho woshishino

<1000ppm izinga lokubekwa kwesiphene

Inkqubo yokuqinisekisa iimpazamo

3. Ukonga imali

Iindleko zokubeka eziphantsi ngenqaku

Imbuyekezo ekhawulezayo kutyalo-mali (ngokuqhelekileyo <18 iinyanga)

Uyilo lolondolozo oluphantsi

V. Iimpawu zezixhobo

1. Intloko yokubeka izinto ezintsha

Uyilo lwenqaba ejikelezayo: Imilomo ye-12 ijikeleza ngokuqhubekayo

Ukukhetha umlomo wombhobho okrelekrele: khetha ngokuzenzekelayo owona mlomo ubalaseleyo

Inkqubo yokulawula i-vacuum: ishaneli yokucoca elawulwa ngokuzimeleyo

2. Inkqubo yombono

I-Flying centering technology inciphisa ixesha lokunqumama

Inkqubo yeekhamera ezimbini iphucula ukuchaneka kokuqaphela

Ukulungiswa kokukhanyisa okuzenzekelayo

3. Inkqubo yokutya

Uyilo lokutshintshwa kwesondlo esikhawulezayo

Tape ubume esweni

Ukungabikho komsebenzi wesilumkiso wezinto eziphathekayo

VI. Iimodyuli ezisebenzayo

1. Inkqubo yokulawula ukubeka

I-algorithm yokwenza i-Motion trajectory optimization

Ulawulo lwesiseko secandelo

Umsebenzi wokuphucula inkqubo

2. Inkqubo yokuqinisekisa umgangatho

Umsebenzi wokuqala wokuhlola

Ukubekwa esweni kwenkqubo yokubeka

Umsebenzi wokurekhoda idatha

3. Inkqubo yolawulo lwemveliso

Ukujongwa kwesimo sezixhobo

Iinkcukacha-manani zokuphumelela kwemveliso

Uhlalutyo lwerekhodi yempazamo

VII. Imiqathango yokusetyenziswa

1. Iimfuno zokusingqongileyo

Ubushushu: 20±3℃

Ukufuma: 40-70%RH

Ukungcangcazela: <0.5G (isiseko esizinzile siyafuneka)

2. Ukusebenza kwemihla ngemihla

Yenza ulungelelwaniso olukhawulezayo ngaphambi kokuba uqalise umatshini yonke imihla

Coca umlomo rhoqo (kucetyiswa rhoqo kwiiyure ezi-4)

Sebenzisa izinto ezityiwayo zantlandlolo (imilomo, iifidi, njl.njl.)

3. Isondlo

Umxholo womjikelo wento

Ukuhlolwa kweNozzle yonke imihla ukunxiba kunye nokucoca

Isikhokelo sokuthambisa Ukugcinwa kweVeki ngeoyile ekhethekileyo yokuthambisa

Ulungelelwaniso lwekhamera Ngenyanga Sebenzisa ibhodi yokulinganisa eqhelekileyo

Uhlolo oluBanzi ngekota Olwenziwa ziinjineli eziziingcali

VIII. Iimpazamo eziqhelekileyo kunye nezisombululo

1. Impazamo: Ukuchola umlomo okulambathayo

Unobangela onokwenzeka:

Ukuvaleka kombhobho

Ivacuum engonelanga

Ulungiselelo olungalunganga lwecandelo

Isisombululo:

Coca okanye ubuyisele umbhobho

Qwalasela inkqubo vacuum

Ukulinganisa kwakhona ubukhulu becandelo

2. Impazamo: Impazamo yokuqondwa kwecandelo

Unobangela onokwenzeka:

Ungcoliseko lwelensi yekhamera

Ukulungiswa kokukhanya okungafanelekanga

Idatha yecandelo elingalunganga

Isisombululo:

Coca ilensi yekhamera

Lungisa iiparamitha zokukhanyisa

Jonga isiseko sedatha yecandelo

3. Impazamo: I-alamu yesistim sokunyakaza

Unobangela onokwenzeka:

Ukungqubana koomatshini

Servo drive engaqhelekanga

Isikhokelo sokuthambisa sikaloliwe esinganelanga

Isisombululo:

Jonga ubume bomatshini

Qala kwakhona inkqubo ye-servo

Thambisa isikhokelo somgca

IX. Izimvo zogcino

1. Ukusombulula ingxaki ngendlela ecwangcisiweyo

Qwalasela isenzeko: rekhoda ikhowudi ye-alam kunye nesimo sesixhobo

Hlalutya oonobangela abanokubakho: bhekisa kwimanyuwali ukumisela umda wempazamo

Inyathelo ngenyathelo lokuphelisa: jonga ukusuka kokulula ukuya kokuntsonkotha

2. Ulandelelwano lokuhlolwa kwecandelo eliphambili

Umbhobho wokufunxa kunye nenkqubo yokufunxa

Ubume bomxhasi

Inkqubo ebonakalayo

Indlela yokunyakaza

Inkqubo yokulawula

3. Inkxaso yobungcali

Sebenzisa SIPLACE isoftwe yoxilongo

Qhagamshelana ne-Siemens inkxaso yobugcisa

Buyisela iindawo ezisetyenzisiweyo ngeendawo zokuqala

10. Ukuma kweMarike

Izixhobo ezikhethwayo zokuVeliswa koMninzi

Eyona nto ingundoqo kuMthengi weMveliso yoMbane woMbane

Imodeli ye-Speed-Speed kunye neNdleko ePhezulu-Esebenzayo

11. Isishwankathelo

Umatshini we-Siemens SIPLACE HS60 we-SMT lolona khetho lufanelekileyo lokwenziwa kobuninzi bezinto zombane:

Imboni-ekhokelayo 60k CPH isantya

Umgangatho we-SMT ozinzileyo

Iindleko zezoqoqosho kunye nokusebenza kakuhle

Lolona khetho lufanelekileyo kwimveliso ye-elektroniki yobuninzi. Ngokulungiswa okusemgangathweni kwemihla ngemihla kunye nokucombulula iingxaki zenzululwazi, izixhobo zinokuqinisekiswa ukuba zisebenza ngokuzinzileyo ixesha elide, zibonelela ngesiqinisekiso esithembekileyo sokwenziwa komgangatho ophezulu we-elektroniki.