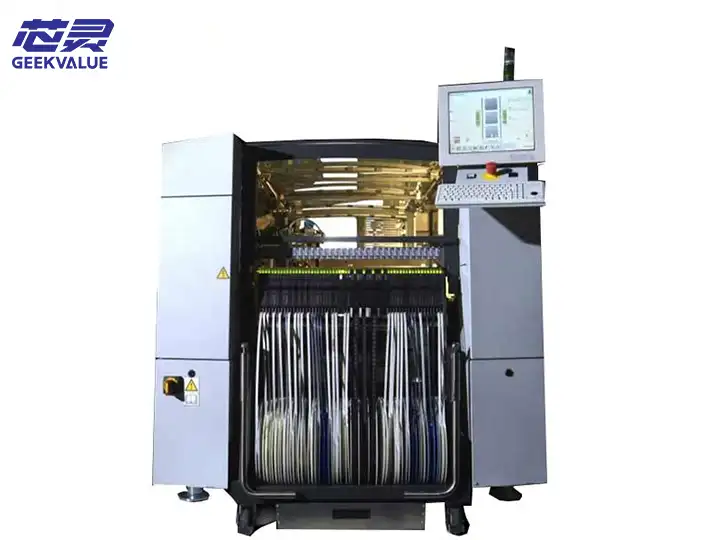

Siemens SIPLACE HS60 ndi makina opangira makina othamanga kwambiri omwe akhazikitsidwa ndi Nokia Electronic Assembly Systems, omwe ali m'gulu la SIPLACE lapamwamba kwambiri. Zipangizozi zidapangidwa kuti zizipanga zida zamagetsi zapamwamba kwambiri, makamaka za:

Consumer electronics (mafoni am'manja, mapiritsi)

Zamagetsi zamagalimoto (njira zosangalatsa zamagalimoto)

Zida zoyankhulirana (ma router, ma switch)

Zida zowongolera zida zapanyumba

II. Mfundo zamakono zamakono

1. Njira yoyenda mothamanga kwambiri

Ntchito yodziyimira pawiri ya cantilever: 2 yodziyimira payokha ya cantilever synchronous kuti ikwaniritse kuyika kofananira

Mutu woyika nsanja: 12 nozzle yozungulira mutu, liwiro lalikulu la 60,000CPH

Linear magnetic levitation drive: X/Y axis imagwiritsa ntchito liniya yamagalimoto, kuthamanga kwa 3.5G

2. Njira yoyikira masomphenya

Ukadaulo wa Flying centering: chizindikiritso chonse cha gawo ndikuyika panthawi yoyika

Makina apawiri kamera:

Kamera yapadziko lonse lapansi yowoneka bwino kwambiri (ya malo a PCB)

Kamera yam'deralo yolondola kwambiri (yozindikiritsa gawo)

3. Dongosolo la chakudya

Intelligent feeder platform:

Thandizani 8mm ~ 56mm tepi feeder

Makina owongolera amtundu wa tepi

Chizindikiritso cha feeder automatic

III. Mafotokozedwe apakati ndi magawo

Zofotokozera za Parameters

Kuyika kolondola ±50μm @ 3σ

Liwiro loyika 60,000 CPH (zongoyerekeza)

chigawo osiyanasiyana 0402 ~ 24 × 24mm (kutalika 12.7mm)

Kuchuluka kwa ma feed Kufikira 72 8mm tepi feeders

Kukula kwa board 50 × 50mm ~ 457 × 356mm

Mphamvu yofunikira 400VAC 3 gawo 7kVA

IV. Ubwino waukulu

1. Kuthamanga kwambiri

Liwiro lakuyika kwa 60k CPH patsogolo pamakampani

0.06 masekondi / kuyika kwa chip kuzungulira

Dual cantilever ikugwira ntchito limodzi

2. Wokhazikika komanso wodalirika

Kapangidwe ka makina olimba amakampani

<1000ppm chiwongola dzanja choyika

Makina otsimikizira zolakwika

3. Zotsika mtengo

Mtengo wotsika poika mfundo iliyonse

Kubwerera mwachangu pazachuma (nthawi zambiri Kukonzekera kochepa kokonza V. Zida zida 1. Kuyika mutu kwatsopano Mapangidwe a nsanja yozungulira: 12 nozzles amazungulira mosalekeza Kusankhidwa kwa nozzle mwanzeru: sankhani zokha mphuno yabwino kwambiri Dongosolo la vacuum control: njira yodziyimira payokha ya vacuum 2. Masomphenya dongosolo Ukadaulo wa Flying centering umachepetsa nthawi yopumira Makina apawiri amakamera amathandizira kuzindikira kulondola Kusintha kounikira zokha 3. Dongosolo la chakudya Kapangidwe kake ka feeder mwachangu Kuwunika mawonekedwe a tepi Kupanda ntchito zochenjeza zakuthupi VI. Ma modules ogwira ntchito 1. Dongosolo loyang'anira malo Motion trajectory optimization algorithm Component database management Ntchito kukhathamiritsa pulogalamu 2. Dongosolo lotsimikizira bwino Chigawo choyamba choyendera ntchito Kuyang'anira ndondomeko yoyika Ntchito yojambulira deta 3. Njira yoyendetsera ntchito Kuwunika mawonekedwe a zida Ziwerengero zopanga bwino Kusanthula zolemba zolakwika VII. Kusamala kuti mugwiritse ntchito 1. Zofuna zachilengedwe Kutentha: 20 ± 3 ℃ Chinyezi: 40-70% RH Kugwedezeka: <0.5G (maziko okhazikika amafunikira) 2. Opaleshoni ya tsiku ndi tsiku Chitani zowongolera mwachangu musanayambe makina tsiku lililonse Tsukani nozzle nthawi zonse (ndikulimbikitsidwa maola 4 aliwonse) Gwiritsani ntchito zopangira zoyambira (nozzles, feeders, etc.) 3. Kusamalira Zinthu Zozungulira Kuyang'ana kwa Nozzle Daily Check kuti yavala ndi kuyeretsa Kuwongolera mafuta Kukonzekera Kwamlungu ndi mlungu ndi mafuta apadera opaka mafuta Kuwongolera kwa kamera Mwezi ndi Mwezi Gwiritsani ntchito bolodi yoyezera Kuwunika kokwanira Kotala Kochitidwa ndi akatswiri odziwa ntchito VIII. Zolakwa zofala ndi zothetsera 1. Cholakwika: Kutopa kosakwanira kwa nozzle Zomwe zingatheke: Kutsekeka kwa nozzle Vacuum yosakwanira Kuyika kwachinthu kolakwika Yankho: Kuyeretsa kapena kusintha nozzle Onani vacuum system Yesaninso makulidwe agawo 2. Cholakwika: Cholakwika chozindikiritsa gawo Zomwe zingatheke: Kuwonongeka kwa lens ya kamera Kuyatsa kolakwika Zolakwika zamagulu Yankho: Yeretsani mandala a kamera Sinthani magawo owunikira Onani gawo la database 3. Cholakwika: Alamu ya kayendedwe ka kayendedwe Zomwe zingatheke: Kugunda kwamakina Servo drive abnormality Kusakwanira kondomulira njanji Yankho: Yang'anani kapangidwe ka makina Yambitsaninso dongosolo la servo Mafuta a linear kalozera IX. Malingaliro osamalira 1. Kuthetsa mwadongosolo Zindikirani chodabwitsachi: lembani nambala ya alamu ndi momwe zida ziliri Unikani zomwe zingayambitse: tchulani bukhuli kuti mudziwe kukula kwa vutolo Kuchotsa pang'onopang'ono: fufuzani kuchokera ku zosavuta mpaka zovuta 2. Kuwunika kwa gawo lofunikira Suction nozzle ndi vacuum system Wodyetsa udindo Zowoneka dongosolo Makina oyenda Dongosolo lowongolera 3. Thandizo la akatswiri Gwiritsani ntchito pulogalamu yoyezetsa matenda a SIPLACE Lumikizanani ndi Nokia thandizo laukadaulo Sinthani zida zosinthira ndi zida zoyambirira 10. Kuyika Msika Zida Zokondedwa Zopangira Misa Mainstream kwa Consumer Electronics Manufacturing Mtundu Wothamanga Kwambiri wokhala ndi Mtengo Wapamwamba-Mwachangu 11. Mwachidule Siemens SIPLACE HS60 SMT Machine ndiye chisankho chabwino kwambiri chopanga zamagetsi ndi: Liwiro lotsogola pamakampani 60k CPH Khalidwe lokhazikika la SMT Ndalama zoyendetsera bwino komanso zachuma Ndilo chisankho choyenera pakupanga magetsi ambiri. Kupyolera mu kukonza koyenera kwa tsiku ndi tsiku ndi kuthetsa mavuto a sayansi, zipangizozi zikhoza kutsimikiziridwa kuti zikugwira ntchito mokhazikika kwa nthawi yaitali, kupereka chitsimikizo chodalirika cha kupanga zamagetsi zapamwamba kwambiri.