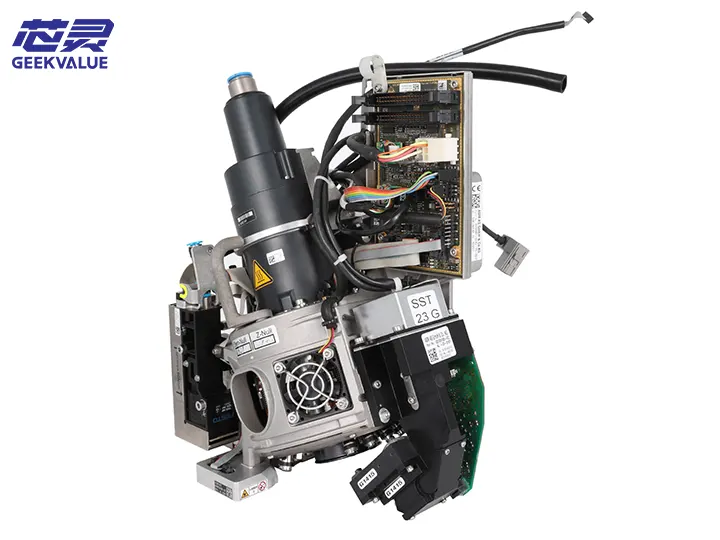

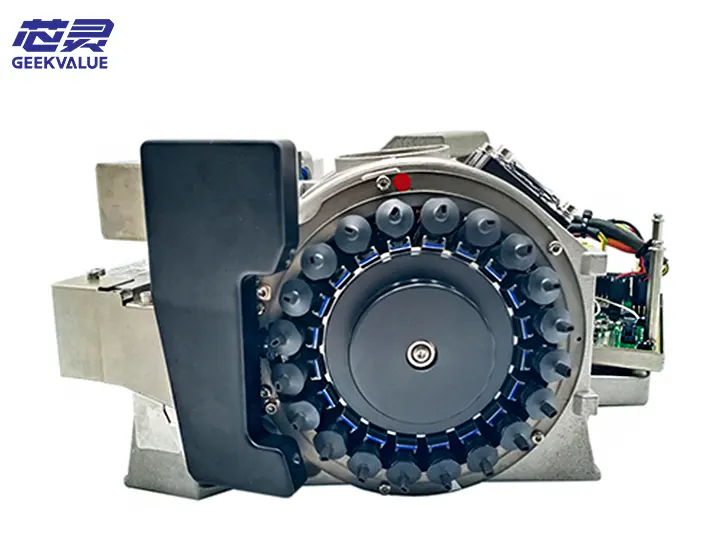

The ASM SIPLACE 2007 nozzle is a medium-to-large component placement nozzle specially designed for SIPLACE placement machines under Siemens. It is mainly used to pick up and place larger SMD components. The nozzle is widely used in SMT production due to its high stability, wear resistance and versatility, and is particularly suitable for production needs in the fields of industrial electronics, automotive electronics and power modules.

2. Core functions and applicable materials

(1) Main types of materials sucked

Power devices:

TO-220, TO-247, DPAK and other power MOSFET/diodes

Large-size electrolytic capacitors (such as φ10mm or above)

Connectors:

Board-to-Board connectors

Headers, sockets

Electromechanical components:

Relays, transformers, inductors

Special-shaped components:

Heat sinks, shielding covers, metal housing components

(2) Functional features

High suction design: The vacuum aperture is large and can stably absorb heavier components (usually supports 5-20g).

Anti-static treatment: Some models use ESD-safe materials to avoid damage to sensitive components.

Wear-resistant tip: Tungsten carbide or ceramic coating to extend service life.

3. Technical specifications

Parameter Specifications

Nozzle type 2007 (standard number)

Applicable component size 5mm×5mm ~ 30mm×30mm (depending on the specific model)

Maximum component weight About 20g (need to be used with a high vacuum generator)

Material Body: Stainless steel (SUS304)

Tip: Tungsten carbide/polyurethane (anti-scratch)

Interface standard Compatible with SIPLACE CP series placement heads (such as CP20, CP12)

Vacuum requirement -70kPa ~ -90kPa (adjusted according to component weight)

4. Structural design

(1) Mechanical structure

Body: Stainless steel precision processing to ensure long-term use without deformation.

Nozzle tip:

Flat head design: suitable for flat components (such as heat sinks).

Groove design: Some models have a concave structure to facilitate the adsorption of components with pins.

Sealing ring: Silicone/O-ring to ensure vacuum tightness.

(2) Special models

2007-ESD: Anti-static version for sensitive components.

2007-HV: High vacuum version for heavier components.

5. Precautions for use

(1) Installation and operation

Correctly match the placement head: Confirm that the nozzle is compatible with the placement head such as CP20/CP12.

Vacuum pressure test: Check for vacuum leakage after installing the new nozzle.

Z-axis height adjustment: Large components require a larger downward stroke to avoid collision.

(2) Maintenance

Regular cleaning:

Use an ultrasonic cleaner (alcohol + deionized water) to remove solder paste residue.

Check for tip wear and replace if necessary.

Sealing check: Use a vacuum detector to test the leakage rate every month.

(3) Taboos

Prohibitions from overweight use: Components over 20g need to be replaced with special nozzles.

Avoid collision with PCB: Large nozzles are easy to scratch the pads, so the height needs to be accurately calibrated.

6. Common problems and solutions

Fault phenomenon Possible cause Solution

Unstable picking 1. Insufficient vacuum

2. Nozzle blockage 1. Check the vacuum line

2. Clean or replace the nozzle

Component placement offset 1. Nozzle deformation

2. Calibration deviation 1. Replace the nozzle

2. Recalibrate the placement coordinates

Component surface scratches 1. The nozzle material is too hard

2. Press down too deep 1. Use polyurethane nozzle instead

2. Adjust Z-axis parameters

High throwing rate 1. Nozzle wear

2. Components are out of specification 1. Replace the nozzle

2. Verify component size matching

7. Alternative solutions

Original nozzle: ASM SIPLACE 2007 (high precision, but higher cost).

Third-party compatible nozzles: such as PH (Panasonic), NozzleMaster and other brands (need to verify compatibility).

8. Conclusion

ASM SIPLACE 2007 nozzles are ideal for handling medium and large components. Their rugged design, high stability and versatility make them indispensable in the fields of power electronics and industrial control. Regular maintenance, correct operation and timely replacement are the key to ensuring production efficiency.