ITekhnoloji yoMphezulu weMount (SMT)yeyona ndlela ibalaseleyo yokudibanisa amacandelo e-elektroniki ngqo kumphezulu weebhodi zesekethe eziprintiweyo (PCBs). Endaweni yokufaka iintambo ezinde kwimingxuma egrunjiweyo njengakwiteknoloji ye- through-hole (THT), i-SMT isebenzisa izinto ezisicaba, ezihlangeneyo ezibizwa ngokubaizixhobo zokukhwela umphezulu (SMDs)ezithengiswa kwipads kumphezulu PCB.

Olu tshintsho lwenziwe lwasebenzaezincinci, khaphukhaphu, kunye ne-elektroniki ekhawulezayo. Ukusuka kwii-smartphones kunye neelaptops ukuya kwiinkqubo zokulawula iimoto kunye nezixhobo zonyango, phantse zonke izixhobo zanamhlanje zixhomekeke kwi-SMT kwimveliso yayo. Izibonelelo zayo ziquka:

Ukuxinana kwecandelo eliphezulu(iminiaturization yeesekethe)

Izantya zemveliso ezikhawulezayonge-automation

Iindleko ezisezantsi zokuvelisangeyunithi nganye

Ukuthembeka okuphuculweyongokunciphisa iziphumo zeparasitic

Ngamagama alula:Ngaphandle kwe-SMT, ii-elektroniki zanamhlanje njengoko sizazi bezingayi kubakho.

Imbali yeTekhnoloji yoMphezulu weNtaba

I-SMT ayizange ivele ngobusuku nje. Indaleko yayo inxibelelene ngokusondeleyo nokukhula okukhawulezayo kwee-elektroniki:

1960s-Imvelaphi kwi-aerospace kunye nomkhosi: Uvavanyo lwangaphambili e-US naseJapan lubonise ukuba ukunyuka kwendawo kunokunciphisa ubunzima kunye nobukhulu-obubalulekileyo kwiisathelayithi kunye neenkqubo zokukhusela.

1970s - Ukwamkelwa kwemizi-mveliso: Iinkampani ezifana ne-IBM kunye ne-Philips zaqala ukwamkela i-SMT kwizicelo zekhompyutha ezixinanisa kakhulu.

1980s-Umthengi we-elektroniki uyakhula: Iinkampani zaseJapan ezifana ne-Sony kunye ne-Panasonic ziphayona i-SMT kwiimveliso zabathengi, zivumela i-Walkmans, i-camcorder, kunye neefowuni zokuqala ukuba zinciphise kakhulu.

1990s – Ukubekwa emgangathweni: Ukupakishwa kwecandelo (i-SOIC, i-QFP, i-BGA) yaba yinto eqhelekileyo kwihlabathi jikelele, okwenza i-SMT ibe yeyona nto iphambili.

2000s-i-Miniaturization wave: Ukunyuka kwee-smartphones, iipilisi, kunye nezixhobo ze-IoT ziqhube i-0201 kunye ne-01005-ubungakanani bezinto ezingenakwenziwa kwimveliso yobuninzi.

2020s-AI kunye neShishini 4.0: Namhlanje, i-SMT iyadibanisaukufunda koomatshini, iirobhothi, kunye nokuveliswa ngobuchuleukufezekisa ukubeka iliso ngexesha lokwenyani kunye nokugcinwa kwangaphambili.

Imigaqo-siseko engundoqo yeNdibano ye-SMT

Embindini wayo, i-SMT ixhomekeke kwiintsika ezintathu:

Uyilo lwePCB lwe-SMT- Iipateni zomhlaba kunye noyilo lwephedi ye-solder kufuneka luhambelaneSMDiimfuno zephakheji.

Ukubekwa kwecandelo elichanekileyo-Khetha-ubeke oomatshini babeka amawaka ee-SMD ngomzuzu.

Inkqubo yeSoldering elawulwayo-Ii-oveni zokuphinda zinyibilike intlama ye-solder ukwenza amalungu aqinileyo, athembekileyo.

Ngokudibanisa la manyathelo kunye nokuhlola kunye novavanyo, abavelisi bafezekisaukuchaneka kunye nokuhambelanaefunekayo kwimveliso ye-elektroniki yobuninzi.

IziXhobo zokuHlaba umphezulu (SMDs)

I-SMT ayinakubakho ngaphandle kwezinto ezikhethekileyo eziyilelwe ukunyuswa komphezulu:

Amacandelo angenakwenziwa

Abaxhathisi(umz., 0402, 0603 iipakethe)

IiCapacitors(i-ceramic multilayer capacitors ilawula i-SMT)

Ii-inductors(isetyenziswa kwiisekethe zeRF, izihluzi, izixhobo zombane)

Amacandelo asebenzayo

Iitransistor kunye neediode(Iiphakheji zeSOT-23)

IiSekethe eziDityanisiweyo (ICs)- ukusuka kwi-microcontrollers ukuya kwi-ASICs

Iiphakheji ze-IC eziqhelekileyo kwi-SMT

I-SOIC (Ulwandlalo oluNcinane lweSekethe eDityanisiweyo)– icwengile, isetyenziswa ngokubanzi.

I-QFP (iPhakeji yeFlethi eneQuad)-Ikhokelela kumacala omane, ilungile kumanani amaphini aphezulu.

QFN (Quad Flat No-Lead)-ukungasebenzi kakuhle kwe-thermal.

I-BGA (Uluhlu lweGridi yeBhola)– usebenzisa iibhola zesolder; idumile kubaqhubekekisi kunye neeFPGAs.

I-CSP (Ipakethe yesikali seChip)– iphantse ilingane nedayiti ngokwayo.

📌 Umzila: Umzi-mveliso uyaqhubeka nokucutha ubungakanani bephakheji, ukusuka ku-0603 ukuya01005 (0.4 × 0.2 mm)amacandelo, umngeni zombini izixhobo kunye nokuphathwa kwabantu.

Umgca weNdibano ye-SMT kunye neZixhobo

Imigca yemveliso ye-SMT yanamhlanje izenzekela kakhulu. Ezona zixhobo ziphambili ziquka:

Isishicileli seNcamathelo ye-Solder-Faka intlama yesolder kwiipads usebenzisa istensile.

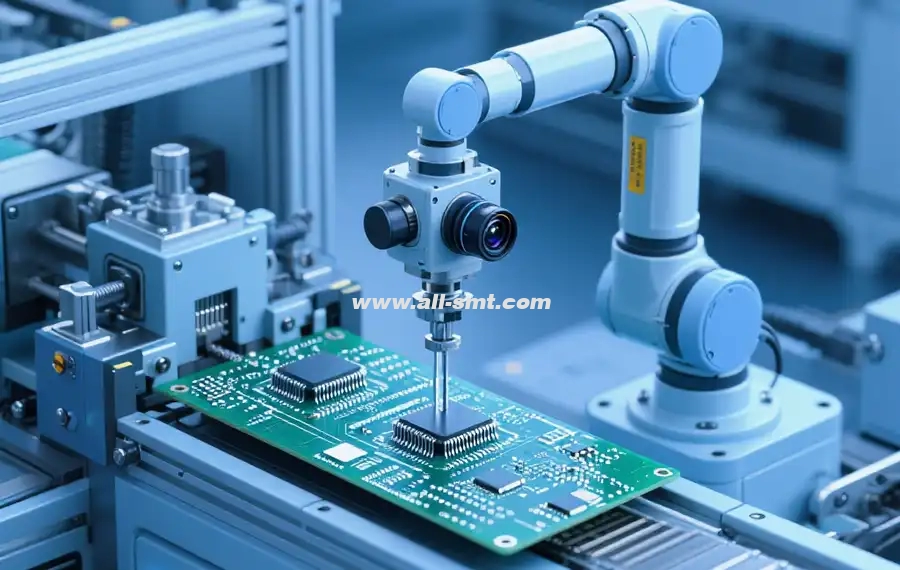

Khetha-ubeke oomatshini -Iirobhothi ezinesantya esiphezulu ezithatha amacandelo kwi-feeders kwaye ziwabeke kwi-PCB.

Iimpawu eziphambili:I-ASM (Siemens), Fuji, Panasonic, Yamaha, JUKI, Samsung.

Iimodeli ezikumgangatho ophezulu zibeka ngaphezulu kwe-100,000 yamacandelo ngeyure.

Hlaziya i-Oven- Ukushisa ibhodi kwiindawo ezilawulwayo ukuze kunyibilike intlama ye-solder.

I-AOI(Uhlolo oluzenzekelayo lwaMacho)-Ijonga ukuchaneka kokubekwa kunye nomgangatho we-solder.

Ukuhlolwa kweX-reyi-Kubalulekile kwi-BGAs kunye namalungu afihliweyo.

IiNkqubo zoMhambisi-Utshintshiselwano oluzenzekelayo phakathi koomatshini.

Rework Stations– Ukulungisa iimpazamo kwiibhodi ezinzima.

Inkqubo yeNdibano ye-SMT Inyathelo ngenyathelo

1. Ushicilelo lwe-Solder Paste

Istencil ihambelana nePCB, kwaye uncamathiselo lusetyenziswa kwiipads.

Umgangatho we-solder paste umthamo uchaphazela ngqo isivuno.

2. Ukubekwa kwecandelo

Iintloko zokuchola kunye nendawo zisebenzisa imilomo yokufunxa ukukhetha izinto.

Ukuchaneka okuphezulu kuyafuneka (± 0.05 mm ukuchaneka).

3. I-Reflow Soldering

I-PCB idlula kwiindawo:tshisa kuqala, thambisa, phinda uqukuqele, upholise.

Iiprofayili zobushushu ezichanekileyo zithintela iziphene ezifana ne-tombstoneing okanye i-voids.

4. Ukuhlolwa noVavanyo

I-AOI ibhaqa iindawo ezingekhoyo/ezingahambi kakuhle.

X-reyi ichonga iziphene ezifihlakeleyo BGAs.

I-ICT (In-Circuit Test) iqinisekisa ukuqhubeka kombane.

5. Ukucoca kunye neCoating Conformal

Kwizinto ze-elektroniki ezithembekileyo (i-automotive, i-aerospace), iibhodi zinokucocwa kwaye zigqunywe ukukhusela.

Iziphene ze-SMT eziqhelekileyo kunye nezisombululo

Ngaphandle kokuzenzekela, iziphene zinokwenzeka:

Ukungcwatywa kwamangcwaba-Izixhasi ezincinci okanye i-capacitors zime ngokuthe tye ngenxa yokumanzisa kwe-solder engalinganiyo.

Isisombululo: Lungisa ivolumu yokuncamathisela ye-solder kunye neprofayili yokubuyisela kwakhona.

Ukudibanisa-I-Solder idibanisa iipads ezikufutshane, ezibangela iifutshane.

Isisombululo: Lungiselela uyilo lwe-stencil, ukunciphisa umthamo wokunamathisela.

I-Voids– Irhasi ebanjiweyo ngaphakathi kumalungu e-solder.

Isisombululo: Ukuphucula ukuqulunqwa kwe-paste, lungisa ukufudumeza.

Amalungu Abandayo– I-soldering ebuthathaka ngenxa yobushushu obungonelanga.

Isisombululo: Guqula i-curve reflow, qinisekisa i-alloy echanekileyo.

Ulungelelwaniso lweCandelo-Ibangelwa kukungcangcazela okanye ukubekwa ngendlela engafanelekanga.

Isisombululo: Phucula ulungelelwaniso lokukhetha kunye nendawo.

Ulawulo lomgangatho kwi-SMT

Ukugcina ukuthembeka okuphezulu, abavelisi baphumeza:

I-SPI (Uhlolo lweNcama ye-Solder)– Iqinisekisa ubukhulu obuchanekileyo bokuncamathisela.

I-AOI-Ichonga iindawo ezingekhoyo, ezingalungelelwanga kakuhle, okanye ezinamatye amangcwaba.

I-ICT (Uvavanyo lweSekethe)– Iqinisekisa umsebenzi wesekethe.

Flying Probe Testing-Uvavanyo oluguquguqukayo lweeprototypes.

Uvavanyo olusebenzayo-Ukulinganisa ukusebenza kokuphela kokusetyenziswa.

Usetyenziso lwe-SMT kuwo wonke amaShishini

I-Electronics yabathengi-Ii-smartphone, iiTV, izinto ezinxitywayo.

I-Automotive Electronics– Iiyunithi zoLawulo lweeNjini (ECUs), iinkqubo ze-ADAS.

I-Industrial Automation-Ii-PLCs, abaqhubi beemoto, iirobhothi.

Izixhobo zonyango- Iinkqubo ze-Endoscopy, ukuxilongwa okuphathekayo.

I-Aerospace kunye noKhuseleko-IiAvionics, iinkqubo zesathelayithi.

Unxibelelwano-Izikhululo ezisisiseko ze-5G, iirotha, iinkqubo zefiber-optic.

Izinto eziluncedo kwiTekhnoloji yoMphezulu weNtaba

Uxinaniso oluphezulu lwecandelo → uyilo olubambeneyo.

Imveliso ekhawulezayo → ukuya kuthi ga kwi-100,000 yokubekwa ngeyure.

Iindleko eziphantsi → ukugrumba okuncinci, izinto ezincinci.

Ukuthembeka okuphezulu → iziphumo ezimbalwa zeparasitic.

Ukukala → ilungele zombini iprototyping kunye nemveliso yobuninzi.

Imingeni kunye neMida ye-SMT

Utyalo-mali lokuqala oluphezulu– Oomatshini nee-oveni zibiza izigidi.

Ubunzima bokusebenza kwakhona– Amacandelo amancinane kunzima ukulungisa ngesandla.

Ulawulo lobushushu-Ii-ICs ezinamandla aphezulu zivelisa ubushushu.

Imida ye-miniaturization-Ukuphatha abantu akunakwenzeka ngaphantsi kwe-01005.

Umngcipheko womgunyathi-Amacandelo e-SMD anokufakwa kwimixokelelwane yokubonelela.

Ikamva le-SMT

I-SMT iyaqhubeka nokuvela:

I-AI kunye nokuFunda koomatshini-Yengeza ukubekwa kunye noqikelelo lwesiphene.

Ukupakishwa kwe-3D kunye ne-SiP-Ukudibanisa iichips ezininzi kwiphakheji enye.

Ii-Eletroniki eziguquguqukayo kunye neziNxitywayo-I-SMT kwiplastiki okanye kwilaphu substrates.

I-Eco-friendly Materials-I-solder yasimahla, ukuthotyelwa kweRoHS.

Umzi-mveliso 4.0 Umanyano-Iifektri ezihlakaniphile ezinedatha yexesha lokwenyani.

Imbonakalo yeMarike 2025–2035: Abahlalutyi baqikelela ukuba imakethi yezixhobo ze-SMT yehlabathi iya kudlulaI-USD 15 yezigidigidingo-2030, eqhutywa yi-automotive electronics kunye ne-IoT.

I-Surface Mount Technology (SMT) sisiseko soshishino lwale mihla lombane. Yenza i-miniaturization, imveliso yobuninzi, kunye nokusebenza kakuhle kweendleko, okwenza indlela yokuphila yanamhlanje yobuchwepheshe obuphezulu yenzeke.

Ukusuka kwii-smartphones kunye neenethiwekhi ze-5G ukuya kwi-elektroniki yezonyango kunye neemoto, i-SMT ikhona yonke indawo-kwaye iya kuqhubeka nokuguquka kunye nobuchwepheshe obutsha njenge-AI, i-IoT, kunye nezixhobo eziguquguqukayo.

Kwiinjineli, abavelisi, kunye nabathengi, ukubamba i-SMT ayisosakhono nje—sisitshixo sokuhlala ukhuphisana kwimarike ye-elektroniki yehlabathi.

FAQ

-

Yintoni iteknoloji yokunyuka komphezulu (SMT)?

Itekhnoloji ye-Surface Mount (SMT) yindlela yokuhlanganisa ye-PCB ethengisa izixhobo eziphezu komhlaba (SMDs) ngokuthe ngqo kwiipadi ebhodini, ivumela ukuxinana kwecandelo eliphezulu, izinto ezincinci zeefom, kunye nemveliso ezenzekelayo enesantya esiphezulu. Xa kuthelekiswa nobuchwepheshe be- through-hole (THT), i-SMT inciphisa ukugrunjwa, iphucula imfezeko yomqondiso, kwaye yehlisa iindleko zeyunithi yokwenziwa kobuninzi.

-

Ingaba indibano ye-SMT isebenza njani inyathelo nenyathelo?

Inkqubo ye-SMT ibandakanya ukuprintwa kwe-solder paste (i-stencil + SPI), i-pick-and-place ye-SMDs, i-reflow soldering (preheat / soak / reflow / cool), kunye nokuhlolwa (AOI / X-ray) kunye novavanyo olusebenzayo / lwe-ICT. Uyilo olululo lwephedi yeDFM, uncamathisele lolawulo lwevolumu, kunye neprofayili yokulungisa iprofayili isivuno sokuqala sokupasa.

-

I-SMT vs THT: yeyiphi endimele ndiyikhethe?

Sebenzisa i-SMT ukwenza i-miniaturization, isantya, kunye nokusebenza kakuhle kweendleko; khetha i-THT apho ukuqina koomatshini kubaluleke kakhulu (iziqhagamshelo, iindawo ezinoxinzelelo oluphezulu, iziphumlisi ezinkulu). Uyilo oluninzi lwamkela itekhnoloji exubeneyo: i-SMT kuninzi lwamacandelo kunye neTHT kwizihlanganisi ezinzima okanye eziphezulu zangoku.