Surface Mount Technology (SMT) is the dominant method of assembling electronic components directly onto the surface of printed circuit boards (PCBs). Instead of inserting long leads through drilled holes as in through-hole technology (THT), SMT uses flat, compact components called surface mount devices (SMDs) that are soldered to pads on the PCB surface.

This innovation has enabled smaller, lighter, and faster electronics. From smartphones and laptops to automotive control systems and medical equipment, nearly every modern device relies on SMT for its production. Its advantages include:

High component density (miniaturization of circuits)

Faster production speeds with automation

Lower manufacturing cost per unit

Improved reliability through reduced parasitic effects

In simple terms: Without SMT, modern electronics as we know them would not exist.

The History of Surface Mount Technology

SMT did not appear overnight. Its evolution is closely tied to the rapid growth of electronics:

1960s – Origins in aerospace & military: Early experiments in the U.S. and Japan showed that surface mounting could reduce weight and size—crucial for satellites and defense systems.

1970s – Industrial adoption: Companies like IBM and Philips began adopting SMT for high-density computing applications.

1980s – Consumer electronics boom: Japanese companies such as Sony and Panasonic pioneered SMT in consumer products, allowing Walkmans, camcorders, and early mobile phones to shrink dramatically.

1990s – Standardization: Component packaging (SOIC, QFP, BGA) became globally standardized, making SMT the mainstream.

2000s – Miniaturization wave: The rise of smartphones, tablets, and IoT devices drove 0201 and 01005-sized passive components into mass production.

2020s – AI and Industry 4.0: Today, SMT integrates machine learning, robotics, and smart manufacturing to achieve real-time quality monitoring and predictive maintenance.

Core Principles of SMT Assembly

At its core, SMT relies on three pillars:

PCB Design for SMT – Land patterns and solder pad layouts must match SMD package requirements.

Precise Component Placement – Pick-and-place machines position thousands of SMDs per minute.

Controlled Soldering Process – Reflow ovens melt solder paste to form strong, reliable joints.

By combining these steps with inspection and testing, manufacturers achieve the accuracy and consistency required for mass electronics production.

Surface Mount Devices (SMDs)

SMT would not exist without specialized components designed for surface mounting:

Passive Components

Resistors (e.g., 0402, 0603 packages)

Capacitors (ceramic multilayer capacitors dominate SMT)

Inductors (used in RF circuits, filters, power supplies)

Active Components

Transistors & diodes (SOT-23 packages)

Integrated Circuits (ICs) – from microcontrollers to ASICs

Common IC Packages in SMT

SOIC (Small Outline Integrated Circuit) – compact, widely used.

QFP (Quad Flat Package) – leads on all four sides, good for high pin counts.

QFN (Quad Flat No-Lead) – leadless, excellent thermal performance.

BGA (Ball Grid Array) – uses solder balls; popular for processors and FPGAs.

CSP (Chip Scale Package) – nearly the same size as the die itself.

📌 Trend: The industry continues to shrink package sizes, moving from 0603 to 01005 (0.4 × 0.2 mm) components, challenging both equipment and human handling.

SMT Assembly Line and Equipment

Modern SMT production lines are highly automated. The main equipment includes:

Solder Paste Printer – Applies solder paste onto pads using a stencil.

Pick-and-Place Machines – High-speed robots that pick components from feeders and place them on the PCB.

Leading brands: ASM (Siemens), Fuji, Panasonic, Yamaha, JUKI, Samsung.

High-end models place over 100,000 components per hour.

Reflow Oven – Heats the board in controlled zones to melt solder paste.

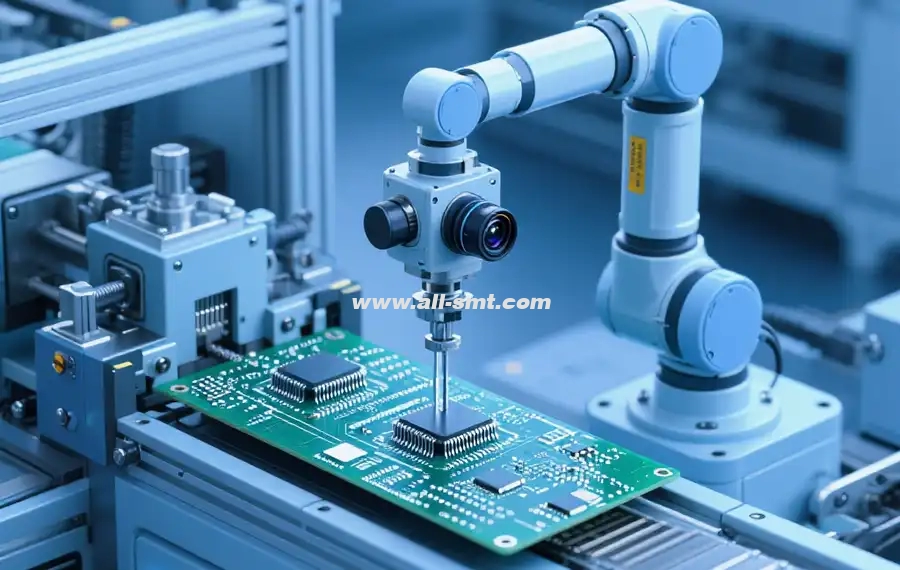

AOI (Automated Optical Inspection) – Checks placement accuracy and solder quality.

X-ray Inspection – Critical for BGAs and hidden joints.

Conveyor Systems – Automate transfer between machines.

Rework Stations – For correcting errors on complex boards.

SMT Assembly Process Step by Step

1. Solder Paste Printing

A stencil aligns with the PCB, and paste is applied to pads.

The quality of solder paste volume directly impacts yield.

2. Component Placement

Pick-and-place heads use vacuum nozzles to pick components.

High precision is required (±0.05 mm accuracy).

3. Reflow Soldering

The PCB passes through zones: preheat, soak, reflow, cooling.

Correct temperature profiles prevent defects like tombstoning or voids.

4. Inspection & Testing

AOI detects missing/misaligned parts.

X-ray identifies hidden defects in BGAs.

ICT (In-Circuit Test) ensures electrical continuity.

5. Cleaning and Conformal Coating

For high-reliability electronics (automotive, aerospace), boards may be cleaned and coated for protection.

Common SMT Defects and Solutions

Despite automation, defects can occur:

Tombstoning – Small resistors or capacitors stand upright due to uneven solder wetting.

Solution: Adjust solder paste volume and reflow profile.

Bridging – Solder connects adjacent pads, causing shorts.

Solution: Optimize stencil design, reduce paste volume.

Voids – Trapped gas inside solder joints.

Solution: Improve paste formulation, adjust heating.

Cold Joints – Weak soldering due to insufficient heat.

Solution: Modify reflow curve, ensure correct alloy.

Component Misalignment – Caused by vibration or improper placement.

Solution: Improve pick-and-place calibration.

Quality Control in SMT

To maintain high reliability, manufacturers implement:

SPI (Solder Paste Inspection) – Ensures correct paste thickness.

AOI – Detects missing, misaligned, or tombstoned parts.

ICT (In-Circuit Test) – Verifies circuit function.

Flying Probe Testing – Flexible testing for prototypes.

Functional Testing – Simulates end-use performance.

Applications of SMT Across Industries

Consumer Electronics – Smartphones, TVs, wearables.

Automotive Electronics – Engine Control Units (ECUs), ADAS systems.

Industrial Automation – PLCs, motor drivers, robotics.

Medical Devices – Endoscopy systems, portable diagnostics.

Aerospace & Defense – Avionics, satellite systems.

Telecommunications – 5G base stations, routers, fiber-optic systems.

Advantages of Surface Mount Technology

High component density → compact designs.

Faster production → up to 100,000 placements/hour.

Lower cost → less drilling, less material.

Higher reliability → fewer parasitic effects.

Scalability → suitable for both prototyping and mass production.

Challenges and Limitations of SMT

High initial investment – Machines and ovens cost millions.

Rework difficulty – Tiny components are hard to repair manually.

Thermal management – High-power ICs generate heat.

Miniaturization limits – Human handling impossible below 01005.

Counterfeit risk – SMD components can be faked in supply chains.

The Future of SMT

SMT continues to evolve:

AI and Machine Learning – Optimize placement and defect prediction.

3D Packaging & SiP – Combining multiple chips in one package.

Flexible & Wearable Electronics – SMT on plastic or textile substrates.

Eco-friendly Materials – Lead-free solder, RoHS compliance.

Industry 4.0 Integration – Smart factories with real-time data.

Market Outlook 2025–2035: Analysts predict the global SMT equipment market will exceed USD 15 billion by 2030, driven by automotive electronics and IoT.

Surface Mount Technology (SMT) is the foundation of the modern electronics industry. It enables miniaturization, mass production, and cost efficiency, making today’s high-tech lifestyle possible.

From smartphones and 5G networks to medical and automotive electronics, SMT is everywhere—and it will continue to evolve alongside new technologies like AI, IoT, and flexible devices.

For engineers, manufacturers, and buyers, mastering SMT is not just a skill—it is the key to staying competitive in the global electronics market.

FAQ

-

What is surface mount technology (SMT)?

Surface mount technology (SMT) is a PCB assembly method that solders surface-mount devices (SMDs) directly onto pads on the board, enabling high component density, smaller form factors, and automated high-speed production. Compared with through-hole technology (THT), SMT reduces drilling, improves signal integrity, and lowers unit cost for mass manufacturing.

-

How does SMT assembly work step by step?

The SMT process includes solder paste printing (stencil + SPI), pick-and-place of SMDs, reflow soldering (preheat/soak/reflow/cool), and inspection (AOI/X-ray) plus functional/ICT testing. Proper DFM pad design, paste volume control, and profile tuning drive first-pass yield.

-

SMT vs THT: which should I choose?

Use SMT for miniaturization, speed, and cost efficiency; choose THT where mechanical robustness matters (connectors, high-stress parts, big passives). Many designs adopt mixed technology: SMT for most components and THT for heavy or high-current connectors.